Page 17 - Application Notebook - Solution for Food Development

P. 17

Application No.C133

News

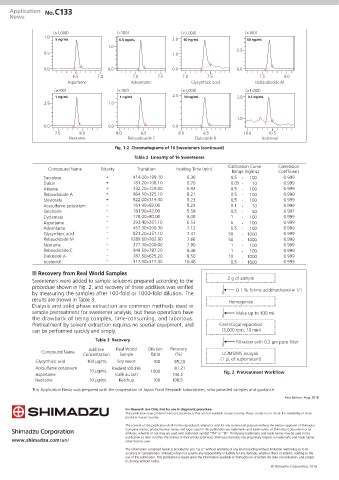

ʢ×1,000 ʣ ʢ×100ʣ ʢ ×1,000ʣ ʢ×100ʣ

1.0

2.0

5 ng/mL

0.5 ng/mL 50 ng/mL 50 ng/mL

1.0

2.5

0.5 1.0

0.0 0.0 0.0 0.0

6.5 7.0 7.0 7.5 7.0 7.5 7.5 8.0

"TQBSUBNF "EWBOUBNF (MZDZSSIJ[JD BDJE 3FCBVEJPTJEF .

ʢ×100ʣ ʢ×100ʣ ʢ×1,000 ʣ ʢ ×1,000ʣ

2.5

1 ng/mL 1 ng/mL 10 ng/mL 2.0 0.5 ng/mL

2.5 1.0

1.0

0.0 0.0 0.0

7.5 8.0 8.0 8.5 8.0 8.5 10.0 10.5

/FPUBNF 3FCBVEJPTJEF $ %VMDPTJEF " *TPTUFWJPM

Fig. 1-2 Chromatograms of 16 Sweeteners (continued)

Table 2 Linearity of 16 Sweeteners

Calibration Curve Correlation

Compound Name Polarity Transition Holding Time (min)

Range (ng/mL) Coefficient

Sucralose + 414.00>199.10 6.36 0.5 ‐ 100 0.999

Dulcin + 181.20>108.10 6.70 0.05 ‐ 10 0.999

Alitame + 332.20>129.00 6.92 0.5 ‐ 100 0.999

Rebaudioside A + 984.50>325.10 8.21 0.5 ‐ 100 0.999

Stevioside + 822.00>319.30 8.23 0.5 ‐ 100 0.999

Acesulfame potassium - 161.90>82.00 5.23 0.1 ‐ 10 0.999

Saccharin - 181.90>42.00 5.58 0.5 ‐ 50 0.997

Cyclamate - 178.00>80.00 6.08 1 ‐ 100 0.999

Aspartame - 293.40>261.10 6.53 5 ‐ 100 0.999

Advantame - 457.30>200.30 7.12 0.5 ‐ 100 0.999

Glycyrrhizic acid - 821.20>351.10 7.41 50 ‐ 1000 0.999

Rebaudioside M - 1289.60>802.90 7.66 50 ‐ 1000 0.999

Neotame - 377.30>200.00 7.90 1 ‐ 100 0.999

Rebaudioside C - 949.50>787.20 8.46 1 ‐ 100 0.999

Dulcoside A - 787.50>625.20 8.50 10 ‐ 1000 0.999

Isosteviol - 317.30>317.30 10.46 0.5 ‐ 1000 0.999

Q Recovery from Real World Samples

2 g of sample

Sweeteners were added to sample solutions prepared according to the

procedure shown in Fig. 2, and recovery of these additives was verified 0.1 % formic acid/methanol = 1/1

by measuring the samples after 100-fold or 1000-fold dilution. The

results are shown in Table 3. Homogenize

Dialysis and solid phase extraction are common methods used in

sample pretreatment for sweetener analysis, but these operations have Make up to 100 mL

the drawback of being complex, time-consuming, and laborious.

Pretreatment by solvent extraction requires no special equipment, and Centrifugal separation

can be performed quickly and simply. (3,000 rpm, 10 min)

Table 3 Recovery Filtration with 0.2 μm pore filter

Additive Real World Dilution Recovery

Compound Name

Concentration Sample Ratio (%) LC/MS/MS analysis

(1 μL of supernatant)

Glycyrrhizic acid 100 μg/mL Soy sauce 100 85.20

Acesulfame potassium Powdered soft drink 81.21

10 μg/mL 1000 Fig. 2 Pretreatment Workflow

Aspartame (café au lait) 104.2

Neotame 10 μg/mL Ketchup 100 108.5

This Application News was prepared with the cooperation of Japan Food Research Laboratories, who provided samples and guidance.

First Edition: Aug. 2016

For Research Use Only. Not for use in diagnostic procedure.

This publication may contain references to products that are not available in your country. Please contact us to check the availability of these

products in your country.

The content of this publication shall not be reproduced, altered or sold for any commercial purpose without the written approval of Shimadzu.

Company names, product/service names and logos used in this publication are trademarks and trade names of Shimadzu Corporation or its

affiliates, whether or not they are used with trademark symbol “TM” or “®”. Third-party trademarks and trade names may be used in this

publication to refer to either the entities or their products/services. Shimadzu disclaims any proprietary interest in trademarks and trade names

www.shimadzu.com/an/ other than its own.

The information contained herein is provided to you "as is" without warranty of any kind including without limitation warranties as to its

accuracy or completeness. Shimadzu does not assume any responsibility or liability for any damage, whether direct or indirect, relating to the

use of this publication. This publication is based upon the information available to Shimadzu on or before the date of publication, and subject

to change without notice.

© Shimadzu Corporation, 2016