Page 29 - Shimadzu Dynamic and Fatigue Testing Systems

P. 29

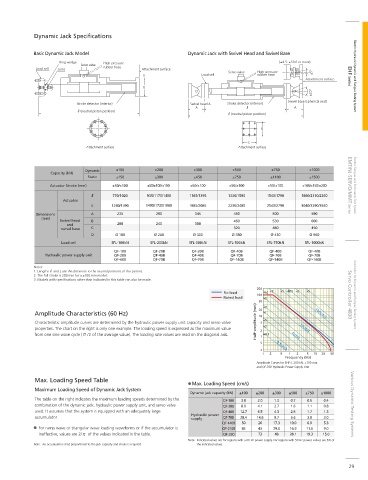

Dynamic Jack Speci cations

Basic Dynamic Jack Model Dynamic Jack with Swivel Head and Swivel Base

Ring wedge High-pressure (±4.5: ±50tf or more)

Servo valve

Load cell Joint rubber hose Attachment surface

Servo valve High-pressure ±5°

E Load cell rubber hose EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

Attachment surface

D

±20°

Swivel base (spherical seat)

Stroke detector (interior) Swivel head A Stroke detector (interior)

A A

(neutral piston position)

(neutral piston position)

B

C

Attachment surface Attachment surface

Dynamic ±100 ±200 ±300 ±500 ±750 ±1000

Capacity (kN)

Static ±150 ±300 ±450 ±750 ±1100 ±1500

Actuator Stroke (mm) ±50/±100 ±50/±100/±150 ±50/±100 ±50/±100 ±50/±100 ±100/±150/±200 EMT/NJ-SERVO/MMT Series Electric Fatigue and Endurance Test System

770/1020 935/1170/1400 1165/1395 1330/1580 1540/1790 1860/2110/2360

Actuator

L 1240/1490 1495/1730/1960 1885/2085 2230/2480 2540/2790 3040/3290/3540

Dimensions A 235 280 345 450 500 590

(mm)

Swivel head B 460 530 600

and 200 240 300

swivel base C 320 440 450

D Ø 180 Ø 240 Ø 300 Ø 380 Ø 430 Ø 560

Load cell SFL-100kN SFL-200kN SFL-300kN SFL-500kN SFL-750kN SFL-1000kN

QF-10B QF-20B QF-20B QF-40B QF-40B QF-40B

Hydraulic power supply unit QF-20B QF-40B QF-40B QF-70B QF-70B QF-70B

QF-40B QF-70B QF-70B QF-140B QF-140B QF-140B

Notes:

1. Lengths and L are the distances to the neutral positions of the pistons.

2. The full stroke is 200 mm for a ±100 mm model.

3. Models with speci cations other than indicated in this table can also be made.

200

No load 100 +10 +2 +5 +100 +2 +5 Controller for Dynamic and Fatigue Testing Systems

Rated load +5 Servo Controller 4830

50

Amplitude Characteristics (60 Hz) 20 +2 100cm/s

+1

10

Characteristic amplitude curves are determined by the hydraulic power supply unit capacity and servo valve Half-amplitude (mm) 5 +5

properties. The chart on the right is only one example. The loading speed is expressed as the maximum value 2 +2 10cm/s

from one sine wave cycle ( /2 of the average value). The loading rate values are read on the diagonal axis. 1 +0.1 1cm/s

5 0.1cm/s

2

1 2 5 1 2 5 10 20 50

Frequency (Hz)

Amplitude Curves for EHF-J, 200 kN, ±100 mm,

and QF-70B Hydraulic Power Supply Unit

Max. Loading Speed Table

Max. Loading Speed (cm/s)

Maximum Loading Speed of Dynamic Jack System

Dynamic jack capacity (kN) ±100 ±200 ±300 ±500 ±750 ±1000

The table on the right indicates the maximum loading speeds determined by the QF-10B 3.8 2.0 1.3 0.7 0.5 0.4

combination of the dynamic jack, hydraulic power supply unit, and servo valve QF-20B 8.0 4.1 2.7 1.6 1.1 0.8 Various Dynamic Testing Systems

used. It assumes that the system is equipped with an adequately large QF-40B 12.7 6.5 4.3 2.5 1.7 1.3

accumulator. Hydraulic power QF-70B 28.4 14.6 9.7 5.6 3.8 3.0

supply

QF-140B 50 26 17.3 10.0 6.9 5.3

For ramp wave or triangular wave loading waveforms or if the accumulator is QF-210B 85 43 29.0 16.9 11.6 9.0

ineffective, values are 2/ of the values indicated in the table. QF-330 73 48 28.1 19.3 15.0

Note: Indicated values are for regions with a 60 Hz power supply. For regions with 50 Hz power, values are 5/6 of

Note: An accumulator sized proportional to the jack capacity and stroke is required. the indicated values.

29