Page 33 - Shimadzu Dynamic and Fatigue Testing Systems

P. 33

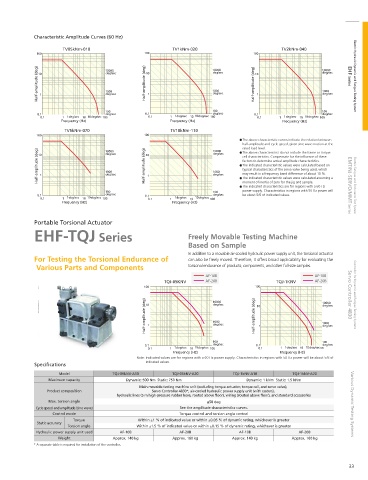

Characteristic Amplitude Curves (60 Hz)

TV05kNm-010 TV1kNm-020 TV2kNm-040

100 100 100

Half-amplitude (deg) 10 1 10000 Half-amplitude (deg) 10 1 10000 Half-amplitude (deg) 10 1 10000 EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

deg/sec

deg/sec

deg/sec

1000

1000

1000

deg/sec

deg/sec

deg/sec

100 100 100

0.1 deg/sec 0.1 deg/sec 0.1 deg/sec

0.1 1 1deg/sec 10 10deg/sec 100 0.1 1 1deg/sec 10 10deg/sec 100 0.1 1 1deg/sec 10 10deg/sec 100

Frequency (Hz) Frequency (Hz) Frequency (Hz)

TV5kNm-070 TV10kNm-110

100 100

The above characteristic curves indicate the relation between

half-amplitude and cycle speed, given sine wave motion at the

rated load level.

Half-amplitude (deg) 1 1000 Half-amplitude (deg) 1 1000 factors to determine actual amplitude characteristics.

10000

10000

The above characteristics do not include the frame or torque

deg/sec

deg/sec

10

10

cell characteristics. Compensate for the in uence of these

The indicated characteristic values were calculated based on

typical characteristics of the servo valve being used, which

may result in a frequency band difference of about 10 %.

deg/sec

deg/sec

The indicated characteristic values were calculated assuming a

moment of inertia of zero for the jig and sample.

The indicated characteristics are for regions with a 60 Hz EMT/NJ-SERVO/MMT Series Electric Fatigue and Endurance Test System

100 100 power supply. Characteristics in regions with 50 Hz power will

0.1 deg/sec 0.1 deg/sec be about 5/6 of indicated values.

0.1 1 1deg/sec 10 10deg/sec 100 0.1 1 1deg/sec 10 10deg/sec 100

Frequency (Hz) Frequency (Hz)

Portable Torsional Actuator

EHF-TQJ Series Freely Movable Testing Machine

Based on Sample

In addition to a movable air-cooled hydraulic power supply unit, the torsional actuator

For Testing the Torsional Endurance of can also be freely moved. Therefore, it offers broad applicability for evaluating the

Various Parts and Components torsional endurance of products, components, and other full-size samples.

AF-10B AF-10B

TQJ-05KNV AF-20B TQJ-1KNV AF-20B

100 10000 100 Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

Half-amplitude (deg) 10 1 deg/sec Half-amplitude (deg) 10 1 10000

deg/sec

1000

1000

deg/sec

deg/sec

100 100

0.1 deg/sec 0.1 deg/sec

0.1 1 1deg/sec 10 10deg/sec 100 0.1 1 1deg/sec 10 10deg/sec 100

Frequency (Hz) Frequency (Hz)

Note: Indicated values are for regions with a 60 Hz power supply. Characteristics in regions with 50 Hz power will be about 5/6 of

indicated values.

Specifications

Model TQJ-05kNV-A10 TQJ-05kNV-A20 TQJ-1kNV-A10 TQJ-1kNV-A20

Maximum capacity Dynamic: 500 Nm Static: 750 Nm Dynamic: 1 kNm Static: 1.5 kNm

Main movable testing machine unit (excluding torque actuator, torque cell, and servo valve),

Product composition Servo Controller 4830*, air-cooled hydraulic power supply unit (with casters),

hydraulic lines (5 m high-pressure rubber hose, routed above floor), wiring (routed above floor), and standard accessories

Max. torsion angle ±50 deg Various Dynamic Testing Systems

Cycle speed and amplitude (sine wave) See the amplitude characteristics curves.

Control mode Torque control and torsion angle control

Torque Within ±1 % of indicated value or within ±0.05 % of dynamic rating, whichever is greater

Static accuracy

Torsion angle Within ±1.5 % of indicated value or within ±0.15 % of dynamic rating, whichever is greater

Hydraulic power supply unit used AF-10B AF-20B AF-10B AF-20B

Weight Approx. 140 kg Approx. 160 kg Approx. 140 kg Approx. 160 kg

* A separate table is required for installation of the controller.

33