Page 36 - Shimadzu Dynamic and Fatigue Testing Systems

P. 36

Energy-Conservation Unit for This product is certi ed as Shimadzu’s

Servopulser Series Hydraulic Power Supply Units Eco-Products Plus.

ECU1 Series: Up to 30% energy savings

ECU Series ECU2 Series: Up to 50% energy savings

compared to previous models

compared to previous models

Helps Reduce Energy Consumption, CO2 Emissions,

and Running Costs by Up to 50 %

Controller Hydraulic Power Source Unit Electric-Hydraulic Servopulser Series

Lower Running Costs

Up to 50 % Using the ECU energy-conservation unit enables an energy-saving mode that can switch OFF the hydraulic power supply unit power depending

Lower Power on the testing parameters and testing status. It also reduces the hydraulic power supply unit's power level when tests are in standby mode.

Consumption

Note: When using the ECU2 in a region with 60 Hz power supply (up to 30 % when using the ECU1).

Automatically Sets the Optimal Energy-Saving Mode

Automatic Used in combination with Microsoft Windows software, the ECU unit can automatically set the optimal energy-saving mode based on test

Energy-Saving parameters or testing status. This ef ciently reduces operating power consumption while continuing to perform intended tests.

Operation

Operation with a Hand-Held Controller

The unit can be operated with a hand-held controller.

The hydraulic power supply unit's energy-saving settings (motor frequency and supply pressure settings) can be set from the Servo

Remote Controller 4830 or from Windows software for 4830.

Operation

Lower Hydraulic Power Supply Unit Operating Noise and Heat Generation

The energy-saving mode reduces the operating noise and heat generated from the hydraulic power supply unit. It also reduces heat

generated from the oil, which helps extend the life of the oil.

ECU Units Can Be Retro tted on Existing Hydraulic Power Supply Units

(QF-A, QF-B, and AF Series)

Notes

For systems using a controller model prior to the Servo Controller 4830, an ECU controller is required.

Retro tting an ECU unit on an existing system requires an on-site survey of the system in advance.

ECU Controller It may not be possible to retro t an ECU unit on existing hydraulic power supply units in poor site conditions.

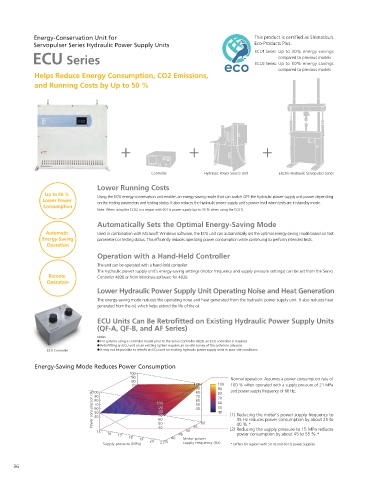

Energy-Saving Mode Reduces Power Consumption

100

90 Normal operation: Assumes a power consumption rate of

80

100

70 100 100 100 % when operated with a supply pressure of 21 MPa

90

60 90 90 and power supply frequency of 60 Hz.

Power consumption (%) 80 100 60 60 (1) Reducing the motor's power supply frequency to

80

80

100

80

50

70

90

70

40

70

60

100

50

50

70

50

90

90

40

40

60

80

80

40

50

70

70

40

35 Hz reduces power consumption by about 25 to

60

60

50

40 %.*

40

40

15 50 50 55 60 (2) Reducing the supply pressure to 15 MPa reduces

16 45 power consumption by about 45 to 55 %.*

17

18 40

19 20 Motor power

Supply pressure (MPa) 21 35 supply frequency (Hz) * Differs for regions with 50 Hz and 60 Hz power supplies

36