Page 24 - Shimadzu Dynamic and Fatigue Testing Systems

P. 24

Compact Hydraulic Actuator System Example

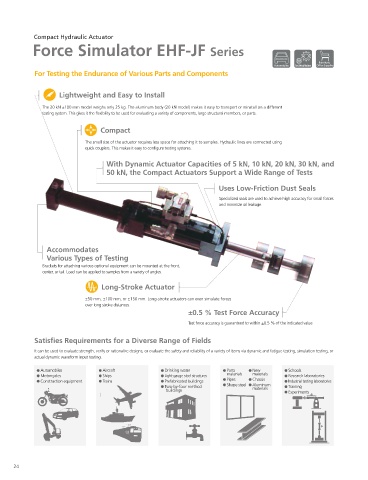

Force Simulator EHF-JF Series Rod end Hydraulic lines

Furniture, Load cell Wiring

Automobiles Steel, Metals, Machines Office Supplies

For Testing the Endurance of Various Parts and Components EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

Servo Controller 4830

Swivel Actuator

Lightweight and Easy to Install

The 20 kN ±100 mm model weighs only 25 kg. The aluminum body (20 kN model) makes it easy to transport or reinstall on a different AF Series Portable Air-Cooled

testing system. This gives it the flexibility to be used for evaluating a variety of components, large structural members, or parts.

Hydraulic Power Supply Unit

Bracket Software This air-cooled hydraulic power supply unit requires no

Compact cooling water. Also, all of the required hydraulic

equipment is installed in a case mounted on caster

The small size of the actuator requires less space for attaching it to samples. Hydraulic lines are connected using wheels so that it can be relocated easily.

quick couplers. This makes it easy to configure testing systems.

With Dynamic Actuator Capacities of 5 kN, 10 kN, 20 kN, 30 kN, and

50 kN, the Compact Actuators Support a Wide Range of Tests

Uses Low-Friction Dust Seals EMT/NJ-SERVO/MMT Series Electric Hydraulic Dynamic and Fatigue Testing System

Specialized seals are used to achieve high accuracy for small forces

and minimize oil leakage.

With a trunnion bracket With vertical and left/right With vertical movement and

Accommodates rotation mechanisms vertical rotation mechanisms

Various Types of Testing

Brackets for attaching various optional equipment can be mounted at the front,

center, or tail. Load can be applied to samples from a variety of angles.

Bed Endurance Evaluation System

Long-Stroke Actuator This system allows testing of bed mattresses or other large

samples. By installing an EHF-J system on a reaction frame, loads

can be repeatedly applied from perpendicular directions. Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

±50 mm, ±100 mm, or ±150 mm. Long-stroke actuators can even simulate forces

over long stroke distances.

±0.5 % Test Force Accuracy

Part Endurance Evaluation System

Test force accuracy is guaranteed to within ±0.5 % of the indicated value

This system features a reaction frame with a hydraulically actuated

crosshead installed on a large surface plate. The actuator can be

Satisfies Requirements for a Diverse Range of Fields adjusted to any angle or left/right position. Therefore, it can be

used as a general-purpose system for testing the endurance of

It can be used to evaluate strength, verify or rationalize designs, or evaluate the safety and reliability of a variety of items via dynamic and fatigue testing, simulation testing, or various parts and components.

actual dynamic waveform input testing.

Automobiles Aircraft Drinking water Parts New Schools

Motorcycles Ships Light-gauge steel structures materials materials Research laboratories XYZ 3-Axis Engine Mount Testing System

Construction equipment Trains Prefabricated buildings Pipes Chassis Industrial testing laboratories This system is capable of applying synchronized loads in three directions, X, Y, and Z.

Two-by-four method Shape steel Aluminum Training

materials

buildings Experiments It can also be used to accurately reproduce actual load profiles experienced by vehicles during travel. Various Dynamic Testing Systems

24 25