Page 23 - Shimadzu Dynamic and Fatigue Testing Systems

P. 23

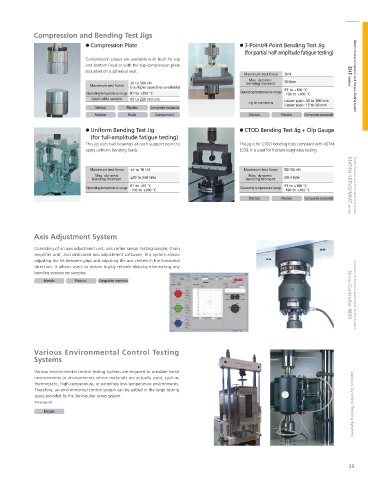

Compression and Bending Test Jigs

Compression Plate 3-Point/4-Point Bending Test Jig

(for partial half-amplitude fatigue testing)

Compression plates are available with both he top

and bottom xed or with the top compression plate

mounted on a spherical seat.

Maximum test force 2kN EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

Max. dynamic

20 to 500 kN bending moment 50 N/m

Maximum test force

(multiple capacities available) RT to +100 °C

Operating temperature range RT to +250 °C Operating temperature range -196 to +300 °C

Applicable sample 60 to 220 mm dia.

Jig dimensions Lower span: 30 to 100 mm

Metals Plastics Composite materials Upper span: 15 to 50 mm

Rubber Rock Component Metals Plastics Composite materials

Uniform Bending Test Jig CTOD Bending Test Jig + Clip Gauge

(for full-amplitude fatigue testing)

This jig uses ball bearings at each support point to This jig is for CTOD bending tests compliant with ASTM

apply uniform bending loads. E339. It is used for fracture toughness testing.

Maximum test force ±2 to 10 kN Maximum test force 50/100 kN

Max. dynamic Max. dynamic

bending moment ±20 to 250 N/m bending moment 2/6 k N/m

RT to +50 °C RT to +100 °C EMT/NJ-SERVO/MMT Series Electric Fatigue and Endurance Test System

Operating temperature range Operating temperature range

-196 to +200 °C -196 to +300 °C

Metals Plastics Composite materials

Axis Adjustment System

Consisting of an axis adjustment unit, axis center sensor testing sample, strain

ampli er unit, and dedicated axis adjustment software, this system allows

adjusting the tilt between grips and adjusting the axis centers in the horizontal

direction. It allows users to obtain highly reliable data by eliminating any

bending stresses on samples.

Metals Plastics Composite materials Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

Various Environmental Control Testing

Systems

Various environmental control testing systems are required to simulate harsh

environments or environments where materials are actually used, such as

thermostatic, high-temperature, or extremely low-temperature environments.

Therefore, an environmental control system can be added in the large testing

space provided by the Servopulser series system.

See page 58. Various Dynamic Testing Systems

Metals

23