Page 21 - Shimadzu Dynamic and Fatigue Testing Systems

P. 21

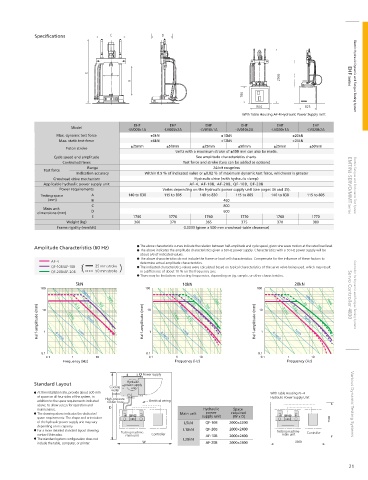

Specifications C D

E B

2566 EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

A

786

904 825

With Table Housing AF-4 Hydraulic Power Supply Unit

EHF EHF EHF EHF EHF EHF

Model

-LV005k1A -LV005k2A -LV010k1A -LV010k2A -LV020k1A -LV020k2A

Max. dynamic test force ±5kN ±10kN ±20kN

Max. static test force ±6kN ±12kN ±24kN

±25mm ±50mm ±25mm ±50mm ±25mm ±50mm

Piston stroke

Units with a maximum stroke of ±100 mm can also be made.

Cycle speed and amplitude See amplitude characteristics charts.

Controlled items Test force and stroke (two can be added as options)

Range 24-bit rangeless

Test force

Indication accuracy Within 0.5 % of indicated value or ±0.02 % of maximum dynamic test force, whichever is greater

Crosshead drive mechanism Hydraulic drive (with hydraulic clamp)

Applicable hydraulic power supply unit AF-4, AF-10B, AF-20B, QF-10B, QF-20B EMT/NJ-SERVO/MMT Series Electric Fatigue and Endurance Test System

Power requirements Varies depending on the hydraulic power supply unit (see pages 34 and 35).

Testing space A 140 to 830 115 to 805 140 to 830 115 to 805 140 to 830 115 to 805

(mm) B 460

C 800

Main unit

dimensions (mm) D 600

E 1760 1770 1760 1770 1760 1770

Weight (kg) 360 370 365 375 370 380

Frame rigidity (mm/kN) 0.0033 (given a 500 mm crosshead-table clearance)

Amplitude Characteristics (60 Hz) The above characteristic curves indicate the relation between half-amplitude and cycle speed, given sine wave motion at the rated load level.

The above indicates the amplitude characteristics given a 60 Hz power supply. Characteristics with a 50 Hz power supply will be

about 5/6 of indicated values.

The above characteristics do not include the frame or load cell characteristics. Compensate for the in uence of these factors to

AF-4 determine actual amplitude characteristics.

QF-10B/AF-10B 25 mm stroke The indicated characteristics values were calculated based on typical characteristics of the servo valve being used, which may result

QF-20B/AF-20B 50 mm stroke in a difference of about 10 % on the frequency axis.

There may be limitations on testing frequencies, depending on jig, sample, or other characteristics.

5kN 10kN 20kN

100 100cm/s 100G 100 100cm/s 100G 100 1G 100cm/s 100G Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

Half-amplitude (mm) 10 1 0.1cm/s 0.01G 0.1G 10cm/s 10G Half-amplitude (mm) 10 1 0.1cm/s 0.01G 10cm/s 0.1G 10G Half-amplitude (mm) 10 1 0.1cm/s 0.01G 0.1G 10cm/s 10G

1G

1G

1cm/s

1cm/s

1cm/s

0.1 0.1 0.1

0.1 1 10 0.1 1 10 0.1 1 10

Frequency (Hz) Frequency (Hz) Frequency (Hz)

Power supply

Hydraulic

Standard Layout power supply

Cooling unit

water

At the installation site, provide about 500 mm With Table Housing AF-4

of space on all four sides of the system, in High-pressure Hydraulic Power Supply Unit

addition to the space requirements indicated rubber hose Electrical wiring

above, to allow access for operation and Various Dynamic Testing Systems

maintenance. Hydraulic Space

The drawing above indicates the dedicated Main unit power required

space requirements. The shape and orientation supply unit (W x D)

of the hydraulic power supply unit may vary L5kN QF-10B 2000×2200

depending on its capacity.

For a more detailed standard layout drawing, Testing machine L10kN QF-20B 2000×2400 Testing machine Controller

contact Shimadzu. main unit Controller AF-10B 2000×2400 main unit

The standard system con guration does not L20kN

include the table, computer, or printer. AF-20B 2000×2400

21