Page 16 - Shimadzu Dynamic and Fatigue Testing Systems

P. 16

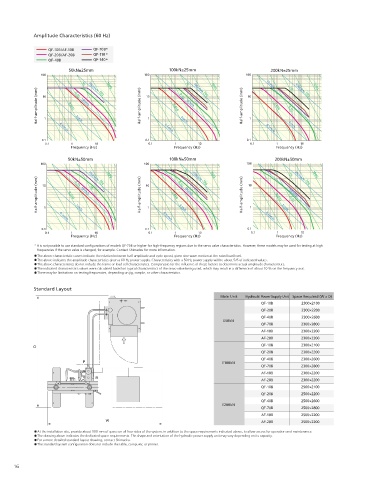

Amplitude Characteristics (60 Hz)

Electric-Hydraulic Dynamic and Fatigue Testing System

QF-10B/AF-10B QF-70B* EHF-U Series

QF-20B/AF-20B QF-110 *

QF-40B QF-140*

Civil Engineering,

Automobiles Steel, Metals, Machines Construction R&D

50kN±25mm 100kN±25mm 200kN±25mm

100 100 100 For Full-Scale Fatigue and Endurance Testing of EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

Structural Materials and Large Samples

1G

1G

10cm/s

100G

Half-amplitude (mm) 10 1 0.01G 0.1G 10cm/s Half-amplitude (mm) 10 1 0.01G 0.1G 10cm/s Half-amplitude (mm) 10 1 0.01G 0.1G By providing a T-slot surface plate at the bottom of a U-type loading frame with a top-mounted actuator, these systems allow installation of extra

100G

100G

1G

100cm/s 10G

100cm/s 10G

100cm/s 10G

large components and parts. Due to the large testing space, dynamic testing and evaluation can be performed on a variety of samples, including

full-size samples and structural members.

1cm/s

1cm/s

0.1 0.1cm/s 0.1 0.1cm/s 0.1 0.1cm/s 1cm/s Rated Actuator Capacities of

0.1 1 10 0.1 1 10 0.1 1 10

Frequency (Hz) Frequency (Hz) Frequency (Hz) 50 kN, 100 kN, and 200 kN Support

a Wide Range of Dynamic Testing

50kN±50mm 100kN±50mm 200kN±50mm

100 100cm/s 10G 100G 100 1G 100cm/s 10G 100G 100 1G 100cm/s 10G 100G

Half-amplitude (mm) 10 0.01G 0.1G 10cm/s 1G Half-amplitude (mm) 10 0.01G 0.1G 10cm/s Half-amplitude (mm) 10 0.01G 10cm/s Top-Mounted Actuator Hydraulically EMT/NJ-SERVO/MMT Series Electric Hydraulic Dynamic and Fatigue Testing System

Supports dynamic and endurance testing of full-size samples, large components,

and structural members.

lifting/lowering crosshead

0.1G

1

1

1

1cm/s

1cm/s

1cm/s

±0.5 % test force accuracy

0.1cm/s

0.1cm/s

0.1cm/s

0.1 0.1 0.1 Test force accuracy is guaranteed to within ±0.5 % of the indicated value.

0.1 1 10 0.1 1 10 0.1 1 10

Frequency (Hz) Frequency (Hz) Frequency (Hz)

* It is not possible to use standard configurations of models QF-70B or higher for high-frequency regions due to the servo valve characteristics. However, these models may be used for testing at high

frequencies if the servo valve is changed, for example. Contact Shimadzu for more information.

The above characteristic curves indicate the relation between half-amplitude and cycle speed, given sine wave motion at the rated load level.

The above indicates the amplitude characteristics given a 60 Hz power supply. Characteristics with a 50 Hz power supply will be about 5/6 of indicated values.

The above characteristics do not include the frame or load cell characteristics. Compensate for the influence of these factors to determine actual amplitude characteristics.

The indicated characteristics values were calculated based on typical characteristics of the servo valve being used, which may result in a difference of about 10 % on the frequency axis.

There may be limitations on testing frequencies, depending on jig, sample, or other characteristics.

High Rigidity and Large Testing Space

Standard Layout

A T-slot surface plate makes it easy to secure samples.

Main Unit Hydraulic Power Supply Unit Space Required (W x D) Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

The size of the surface plate and length of the columns can be customized High-accuracy column

QF-10B 2300×2100

based on the size of samples.

QF-20B 2300×2200

QF-40B 2300×2600

E50kN

QF-70B 2300×2800

AF-10B 2300×2200

AF-20B 2300×2200

QF-10B 2300×2100

QF-20B 2300×2200

QF-40B 2300×2600

E100kN

QF-70B 2300×2800

AF-10B 2300×2200

AF-20B 2300×2200

QF-10B 2500×2100

QF-20B 2500×2200

Crosshead drive handle

QF-40B 2500×2600

E200kN Various Dynamic Testing Systems

QF-70B 2500×2800

AF-10B 2500×2200 Crosshead Drive System with

AF-20B 2500×2200

Operating Error Prevention Mechanism

At the installation site, provide about 500 mm of space on all four sides of the system, in addition to the space requirements indicated above, to allow access for operation and maintenance.

The drawing above indicates the dedicated space requirements. The shape and orientation of the hydraulic power supply unit may vary depending on its capacity. The hydraulic crosshead drive and hydraulic clamp can be operated intuitively

For a more detailed standard layout drawing, contact Shimadzu.

The standard system configuration does not include the table, computer, or printer. using the handle.

16 17