Page 27 - Shimadzu Dynamic and Fatigue Testing Systems

P. 27

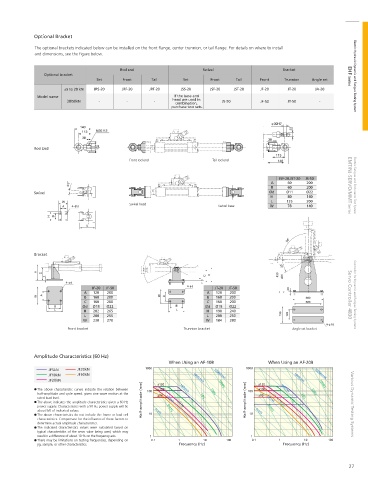

Optional Bracket

The optional brackets indicated below can be installed on the front ange, center trunnion, or tail ange. For details on where to install

and dimensions, see the gure below.

Rod end Swivel Bracket

Optional bracket EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

Set Front Tail Set Front Tail Front Trunnion Angle set

±5 to 20 kN JRS-20 JRF-20 JRT-20 JSS-20 JSF-20 JST-20 JF-20 JT-20 JA-20

Model name If the base and

30/50kN - - - head are used in JS-50 JF-50 JT-50 -

combination,

purchase two sets.

Rod End

Front rod end Tail rod end

JSF-20,JST-20 JS-50

A 60 200

B 60 200 EMT/NJ-SERVO/MMT Series Electric Fatigue and Endurance Test System

Swivel Ød Ø11 Ø22

H 80 140

L 135 200

Swivel head

Swivel base W 78 140

Bracket

JF-20 JF-50 JT-20 JT-50

A 120 200 A 120 200

B 160 200 B 160 200 Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

C 160 200 C 160 200

Ød Ø18 Ø22 Ød Ø18 Ø22

H 202 265 H 190 240

L 200 255 L 200 250

W 230 270 W 184 280

Front bracket Trunnion bracket Angle set bracket

Amplitude Characteristics (60 Hz)

When Using an AF-10B When Using an AF-20B

JF5kN JF30kN 1000 1000

JF10kN JF50kN 10000cm/s 10000cm/s

JF20kN ±150 1000cm/s 1000G ±150 1000cm/s 1000G

The above characteristic curves indicate the relation between 100 ±100 100cm/s 100 ±100 100cm/s

half-amplitude and cycle speed, given sine wave motion at the ±50 100G ±50 100G

rated load level. 10cm/s 10G 10cm/s 10G

The above indicates the amplitude characteristics given a 60 Hz Half-amplitude (mm) 1G Half-amplitude (mm) 1G

power supply. Characteristics with a 50 Hz power supply will be 0.1G 0.01G 0.1G Various Dynamic Testing Systems

about 5/6 of indicated values. 1cm/s 0.01G 1cm/s

The above characteristics do not include the frame or load cell 10 10

characteristics. Compensate for the in uence of these factors to

determine actual amplitude characteristics.

The indicated characteristics values were calculated based on

typical characteristics of the servo valve being used, which may

result in a difference of about 10 % on the frequency axis. 1 1

There may be limitations on testing frequencies, depending on 0.1 1 10 100 0.1 1 10 100

jig, sample, or other characteristics. Frequency (Hz) Frequency (Hz)

27