Page 51 - Application Notebook - Solution for Food Development

P. 51

LAAN-A-LM-E105

Application Liquid Chromatography Mass Spectrometry

News Multi-Component Analysis of Five Beers

No.C134

Sensory test methods that present flavor and n Beer Sample Preparation and Analysis

t a s t e in n u m e r i c a l t er m s a r e w i d e l y us e d An internal standard was added to 0.2 mL of degassed

techniques for the quantitative evaluation of food beer, and ultrafiltration was performed on this mixture

quality. Recently, attempts have been made to using a molecular weight cut off filter. The filtrate was

obtain a greater amount of data by combining the recovered, diluted 200 times, and then used for

results of sensory tests with metabolomics data simultaneous analysis by LC/MS. LC/MS analysis was

that provides a comprehensive analysis of food performed according to analytical conditions in the

constituents. Combining comprehensive analytical primary metabolite method package. The analytical

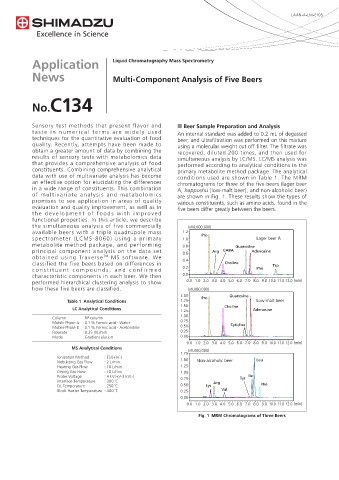

data with use of multivariate analysis has become conditions used are shown in Table 1. The MRM

an effective option for elucidating the differences chromatograms for three of the five beers (lager beer

in a wide range of constituents. This combination A, happoshu [low-malt beer], and non-alcoholic beer)

of multivariate analysis and metabolomics are shown in Fig. 1. These results show the types of

promises to see application in areas of quality various constituents, such as amino acids, found in the

evaluation and quality improvement, as well as in five beers differ greatly between the beers.

the development of foods with impr oved

functional properties. In this article, we describe

the simultaneous analysis of five commercially (x10,000,000)

available beers with a triple quadrupole mass 1.2

spectrometer (LCMS-8060) using a primary 1.0 Pro Lager beer A

metabolite method package, and performing 0.8 Guanosine

principal component analysis on the data set 0.6 Arg GABA Adenosine

obtained using Traverse TM MS software. We

classified the five beers based on differences in 0.4 Choline Trp

co nsti tuen t co mpou nds, and conf irm ed 0.2 Phe

characteristic components in each beer. We then 0.0

performed hierarchical clustering analysis to show 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0(min)

how these five beers are classified. (x1,000,000)

2.00 Pro Guanosine

Table 1 Analytical Conditions 1.75 Low-malt beer

1.50 Choline

LC Analytical Conditions Adenosine

1.25

Column : RP column 1.00

Mobile Phase A : 0.1 % Formic acid - Water 0.75 Cytidine

Mobile Phase B : 0.1 % Formic acid - Acetonitrile 0.50

Flowrate : 0.25 mL/min 0.25

Mode : Gradient elution 0.00

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0(min)

MS Analytical Conditions (x1,000,000)

1.75

Ionization Method : ESI(+)/(-) 1.50

Nebulizing Gas Flow : 2 L/min Non-alcoholic beer Leu

Heating Gas Flow : 10 L/min 1.25

Drying Gas Flow : 10 L/min 1.00

Probe Voltage : 4 kV(+)/-3 kV(-) 0.75 Tyr Ile

Interface Temperature : 300 ˚C Arg

DL Temperature : 250 ˚C 0.50 Lys Phe

Block Heater Temperature : 400 ˚C 0.25 Val

0.00

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0(min)

Fig. 1 MRM Chromatograms of Three Beers