Page 29 - Application Handbook - Liquid Chromatography

P. 29

LAAN-A-LC-E279

Application Supercritical Fluid Extraction / Chromatography

News Application of Nexera UC SFE Pretreatment System

for Extracting Pesticide Residues from Soil

No.L503

Evaluating the persistence of pesticides in environmental as shown in Fig. 2. This not only improves productivity

soil is an important criteria for evaluating the safety of and minimizes environmental impact, but also avoids

pesticides and analyzing pesticides in soil is extremely human errors involved in the sample pretreatment

important for initial evaluations or registration of process. Furthermore, a specially designed rack changer

pesticides. However, in most cases, analyzing pesticides can be used to perform extraction consecutively for up

in soil using liquid-liquid extraction to extract the to 48 samples.

pesticides is very time-consuming, requires special * "Miyazaki Hydro-Protect" Patent No. 3645552

equipment and reagents, and can cause problems, such

(A)

as metal ions or other introduced ionic substances (A) CO2 pump Back pressure

contaminating analytical instruments or the target SFE unit regulator Column oven Fraction collector

Pressure

substances being decomposed by oxidation, exothermic CO2 Solvent control ON

reactions, or other consequences of the extraction cylinder delivery pump Trap column

process. 15MPa Atmospheric

In contrast, supercritical fluid extraction (SFE) provides Extraction vessel pressure Collection

tubes

excellent extraction efficiency using supercritical carbon Modifier Eluent

(B)

dioxide as the extraction solvent, which offers the low (B) CO2 pump Back pressure

viscosity and high diffusivity of a gas and the high SFE unit regulator Column oven Fraction collector

Pressure

solubility of a fluid. Consequently, it extracts target CO2 Solvent control ON

substances quickly using smaller quantities of organic cylinder delivery pump Trap column

solvent than existing solvent extraction methods, 15MPa Atmospheric

pressure

making it a more environmentally-friendly method as Extraction vessel Collection

tubes

well. Modifier Eluent

This article describes an example of using the Nexera (C) CO2 pump Back pressure

(C)

UC SFE pretreatment system to extract residual SFE unit regulator Column oven Fraction collector

Pressure

pesticides from soil. CO2 control ON

Solvent

cylinder delivery pump

Trap column

15MPa Atmospheric

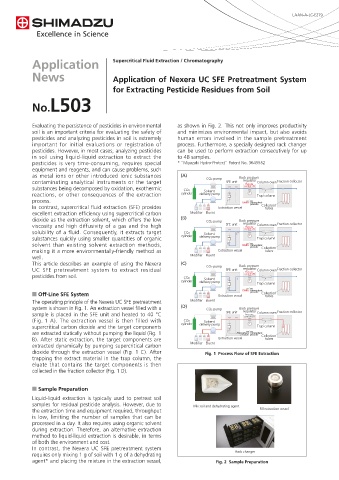

n Off-Line SFE System Extraction vessel pressure Collection

tubes

The operating principle of the Nexera UC SFE pretreatment Modifier Eluent

(D)

system is shown in Fig. 1. An extraction vessel filled with a (D) CO2 pump Back pressure

sample is placed in the SFE unit and heated to 40 °C SFE unit regulator Column oven Fraction collector

Pressure

control OFF

(Fig. 1 A). The extraction vessel is then filled with CO2 Solvent

supercritical carbon dioxide and the target components cylinder delivery pump Trap column

are extracted statically without pumping the liquid (Fig. 1 Atmospheric Atmospheric Collection

pressure

pressure

B). After static extraction, the target components are Extraction vessel tubes

extracted dynamically by pumping supercritical carbon Modifier Eluent

dioxide through the extraction vessel (Fig. 1 C). After Fig. 1 Process Flow of SFE Extraction

trapping the extract material in the trap column, the

eluate that contains the target components is then

collected in the fraction collector (Fig. 1 D).

n Sample Preparation

Liquid-liquid extraction is typically used to pretreat soil

samples for residual pesticide analysis. However, due to Mix soil and dehydrating agent

the extraction time and equipment required, throughput Fill extraction vessel

is low, limiting the number of samples that can be

processed in a day. It also requires using organic solvent

during extraction. Therefore, an alternative extraction

method to liquid-liquid extraction is desirable, in terms

of both the environment and cost.

In contrast, the Nexera UC SFE pretreatment system

requires only mixing 1 g of soil with 1 g of a dehydrating Rack changer

agent* and placing the mixture in the extraction vessel, Fig. 2 Sample Preparation