Page 64 - Shimadzu Dynamic and Fatigue Testing Systems

P. 64

Ultrasonic Fatigue Testing System For Evaluating Fatigue Strength at Cycle Level of Fatigue Strength of SNCM439(B) Steel

USF-2000A Steel, Metals, Machines R&D 10 or Higher 1100 SNCM439(B)

8

C. Masuda et al.

Conventionally, it was assumed that fatigue strength of steel was constant beyond 10 cycles. In

7

Rotating bending,50Hz

other words, it was assumed that fatigue failure would not occur at stresses below the fatigue 1000 Properties of SNCM439(B) Steel

7

limit for 10 cycles. However, we are now learning that in the case of materials strengthened by 900 f Yield stress: 1444 MPa

Tensile strength: 1870 MPa

20 kHz Fatigue Testing quenching or surface treatment, internal inclusions can cause fatigue fractures between 10 and Stress amplitude, S(MPa) f f Vickers hardness: 592 Hv EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

8

7

9

Ultra Efficient for Gigacycle Testing 10 cycles even for stress levels below the 10 fatigue limit. 800 f f f

Therefore, now that products are being used for longer periods at higher speeds, fatigue

Also for Analyzing Inclusions in Metals fractures between 10 and 10 cycles have become an extremely important issue. f

8

9

700

Fracture at stresses below

the 10 7 cycle fatigue limit

10

This ultrasonic fatigue testing system achieves a vibration rate of 20 kHz by applying a vibration Allows tests of 10 cycles to be completed in only six days, 600 f: Fracture from internal

defect

generated by a Piezoelectric element and amplified by a horn. This not only significantly which would normally take 3.2 years at 100 Hz. 1.0x10 4 1.0x10 5 1.0x10 6 1.0x10 7 1.0x10 8 1.0x10 9 1.0x10 10

reduces cycle times, it also helps discover microscopic defects and inclusions in high-strength Number of cycles, N

steel materials, which can cause fatigue fractures at the megacycle level.

Example of the fatigue

For Analyzing Inclusions in Test Materials fracture surface of

high-strength steel

In high-strength steels and other materials, fatigue can propagate from micro defects fractured by the Shimadzu

USF-2000 Ultrasonic

and inclusions inside the material, which are known to result in fatigue fractures at the Fatigue Testing System

Capable of Testing 1000 MPa Class Steel Material gigacycle level. Therefore, identifying and analyzing defects and inclusions in test

materials are useful for developing materials with high fatigue strength. Inclusion where the fatigue

High stresses can be generated by performing tests at resonance frequencies. With a 20 kHz cycle Due to the extremely small size of such defects and inclusions, they are very difficult to fracture originated can be

identified

capacity, this system is able to accelerate fatigue life evaluations of metals and other materials. It is identify using non-destructive methods. Typically, materials were sliced and the section

perfect for long service life evaluation of materials or high-speed vibration testing. surface visually inspected. EMT/NJ-SERVO/MMT Series Electric Hydraulic Dynamic and Fatigue Testing System

However, the efficiency of identifying and analyzing inclusions can be increased

dramatically by using an ultrasonic fatigue testing machine to the point of fatigue

Extremely Economical with Power Consumption of Only 100 W fracture, which ensures a defect or inclusion will be discovered on the fracture surface.

Use of resonance requires only minimal power consumption.

Example of Sample Dimensions (given Young's modulus of 206,000 MPa and density of 7.85 g/cm 3 )

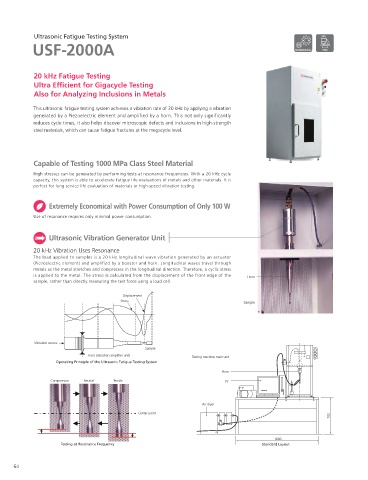

Ultrasonic Vibration Generator Unit

Circular Tapered Sample Notched Sample

20 kHz Vibration Uses Resonance (6.49)

The load applied to samples is a 20 kHz longitudinal wave vibration generated by an actuator M6×0.75 M6×0.75 R3.0

(Piezoelectric element) and amplified by a booster and horn. Longitudinal waves travel through (R58.9)

metals as the metal stretches and compresses in the longitudinal direction. Therefore, a cyclic stress Ø 3.0 Ø10.0 Ø 6.0

is applied to the metal. The stress is calculated from the displacement of the front edge of the Horn

sample, rather than directly measuring the test force using a load cell.

90° Ø10.0

40±0.05

Displacement 60.75±0.05 Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

Stress 9.8±0.05 9.8±0.05

Sample 121.5±0.05

Test stress range: About 200 to 1000 MPa nominal Test stress range: About 140 to 700 MPa nominal

Stress concentration factor: About 1.56 Units: mm

Specifications

Vibration source Test frequency 20 kHz ±500 Hz (recommended test range: 20 kHz ±30 Hz) Note: The test frequency is determined from the resonance frequency of the sample.

Sample Vibration at horn tip ±10 to ±50 µm

Horn (vibration amplifier unit)

Testing machine main unit Test stress range Stress given ±10 to ±50 µm displacement of sample Note: Stress values depend on sample shape and physical property values.

Operating Principle of the Ultrasonic Fatigue Testing System Stress ratio -1

Materials that can be resonated at 20 kHz and generate minimal heat during resonance

Horn Testable materials Example: High-strength steel, duralumin, titanium alloy, aluminum, etc.

Compression Neutral Tensile PC Materials that cannot resonate at 20 kHz

Materials for which samples are difficult to attach

Not-testable materials Materials that generate significant heat during resonance at 20 kHz, due to friction

Examples: Resins, ceramics, etc.

Power requirements 3-phase 200 V: 2 kVA (air compressor) , 1-phase 200V: 3.5 kVA (ultrasonic fatigue testing system) , 1-phase 100V: 1 kVA (computer, displacement logger, air dryer, etc.)

Air dryer USF-2000A Ultrasonic Fatigue Testing System main unit (including table), ultrasonic resonance system, control computer, Various Dynamic Testing Systems

Standard contents ultrasonic testing control and measurement software, and cooling unit (air dryer and compressed air lines)

Center point

700 Note: Air compressor for cooling is not included.

Air compressor (for regions with 50 Hz or 60 Hz power) 3-phase 200 V: 2 kVA

Displacement measuring system (eddy current displacement gauge with 0.5 µm resolution)

Required optional products

Note: A high-speed data logger or digital oscilloscope is required separately for reading voltages output from the displacement gauge.

1600 Displacement gauge calibrator (CDE-25 C1 high-performance micrometer)

Testing at Resonance Frequency Standard Layout Note: Systems can be selected without an air compressor in cases where the customer will supply the compressed air. A 150 L/m flow rate of compressed air at a minimum 0.2 MPa is required.

64 65