Page 37 - Application Notebook - Solution for Food Development

P. 37

LAAN-A-LM-E126

Application Liquid Chromatograph Mass Spectrometry

News

Analysis of Chiral Amino Acids within Fermented

Beverages Utilizing a Column Switching System

No. C156

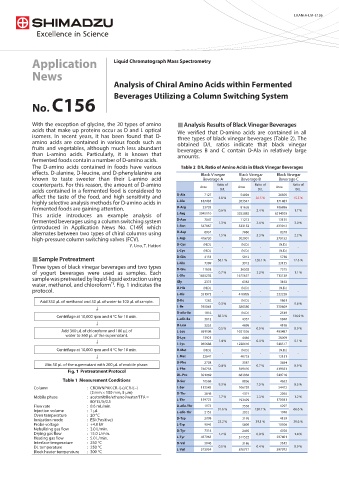

With the exception of glycine, the 20 types of amino Analysis Results of Black Vinegar Beverages

acids that make up proteins occur as D and L optical We verified that D-amino acids are contained in all

isomers. In recent years, it has been found that D- three types of black vinegar beverages (Table 2). The

amino acids are contained in various foods such as obtained D/L ratios indicate that black vinegar

fruits and vegetables, although much less abundant beverages B and C contain D-Ala in relatively large

than L-amino acids. Particularly, it is known that amounts.

fermented foods contain a number of D-amino acids.

The D-amino acids contained in foods have various Table 2 D/L Ratio of Amino Acids in Black Vinegar Beverages

effects. D-alanine, D-leucine, and D-phenylalanine are Black Vinegar Black Vinegar Black Vinegar

known to taste sweeter than their L-amino acid Beverage A Beverage B Beverage C

counterparts. For this reason, the amount of D-amino Area Ratio of Area Ratio of Area Ratio of

acids contained in a fermented food is considered to D/L D/L D/L

affect the taste of the food, and high sensitivity and D-Ala 7127 3.8 % 54094 20.5 % 26505 15.5 %

highly selective analysis methods for D-amino acids in L-Ala 187083 263547 171483

fermented foods are gaining attention. D-Arg 23703 0.6 % 81626 2.4 % 106896 1.7 %

This article introduces an example analysis of L-Arg 3945110 3353883 6214029

fermented beverages using a column switching system D-Asn 7047 1.3 % 11213 3.4 % 13135 3.0 %

(introduced in Application News No. C149) which L-Asn 547867 333152 433012

alternates between two types of chiral columns using D-Asp 6934 1.5 % 7086 2.3 % 8248 2.2 %

high-pressure column switching valves (FCV). L-Asp 476730 302901 370152

Y. Uno, T. Hattori D-Cys (N.D.) - (N.D.) - (N.D.) -

L-Cys (N.D.) (N.D.) (N.D.)

Sample Pretreatment D-Gln 4153 56.1 % 5013 128.1 % 5738 17.3 %

L-Gln 7399 3912 33155

Three types of black vinegar beverages and two types

D-Glu 11658 36502 7575

of yogurt beverages were used as samples. Each L-Glu 1635202 0.7 % 1675657 2.2 % 713130 1.1 %

sample was pretreated by liquid-liquid extraction using Gly 2375 6382 3163

*1

water, methanol, and chloroform . Fig. 1 indicates the D-His (N.D.) (N.D.) (N.D.)

protocol. - - -

L-His 351973 410895 232228

Add 350 μL of methanol and 50 μL of water to 100 μL of sample. D-Ile 1262 (N.D.) 1861

0.3 % - 0.6 %

↓ L-Ile 392041 580580 330869

D-allo-Ile 1816 (N.D.) 2519

Centrifuge at 10,000 rpm and 4 °C for 10 min. 50.3 % - 136.9 %

L-allo-Ile 3612 4357 1840

↓ D-Leu 3255 4698 4198

0.5 % 0.5 % 0.9 %

Add 360 μL of chloroform and 180 μL of L-Leu 691108 1031536 493487

water to 360 μL of the supernatant.

D-Lys 13921 4446 28009

↓ L-Lys 965688 1.4 % 1220610 0.4 % 548517 5.1 %

Centrifuge at 10,000 rpm and 4 °C for 10 min. D-Met (N.D.) (N.D.) (N.D.)

- - -

↓ L-Met 22647 48753 13151

D-Phe 2738 3587 3634

Mix 50 μL of the supernatant with 200 μL of mobile phase. 0.4 % 0.7 % 0.9 %

L-Phe 746758 549410 419561

Pretreatment Protocol

DL-Pro 301069 683984 549718

Table 1 Measurement Conditions D-Ser 10568 8036 4653

9.3 % 7.5 % 8.5 %

Column : CROWNPAK CR-I(+)/CR-I(−) L-Ser 113543 106729 54472

(3 mm × 150 mm, 5 μm) D-Thr 2646 4374 2036

Mobile phase : acetonitrile/ethanol/water/TFA = 1.7 % 2.3 % 1.2 %

80/15/5/0.5 L-Thr 159723 193429 170581

Flow rate : 0.6 mL/min. D-allo-Thr 1973 3538 1297

Injection volume : 1 μL L-allo-Thr 2153 91.6 % 2932 120.7 % 1946 66.6 %

Oven temperature : 20 °C

Ionization mode : ESI (Positive) D-Trp 2098 23.2 % 2195 39.1 % 4159 39.6 %

Probe voltage : +4.0 kV L-Trp 9045 5609 10506

Nebulizing gas flow : 3.0 L/min. D-Tyr 7314 2495 4026

Drying gas flow : 15.0 L/min. 1.7 % 0.8 % 1.4 %

Heating gas flow : 5.0 L/min. L-Tyr 437963 314522 297401

Interface temperature : 250 °C D-Val 3046 3186 3613

DL temperature : 250 °C L-Val 573054 0.5 % 870777 0.4 % 387972 0.9 %

Block heater temperature : 300 °C