Page 24 - Solutions for Plastic Evaluation

P. 24

n

Product Evaluation

Crystallization

Thermal Analysis

Evaluation of Plastic Materials Measurement of Commercial PET Bottles

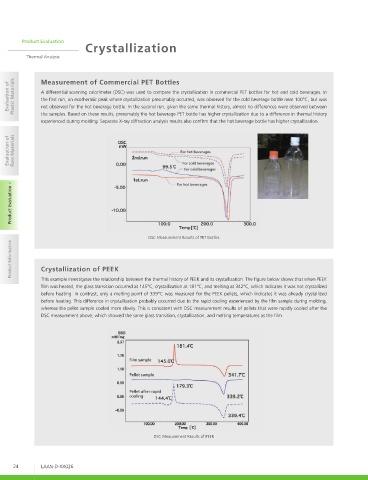

A differential scanning calorimeter (DSC) was used to compare the crystallization in commercial PET bottles for hot and cold beverages. In

the first run, an exothermic peak where crystallization presumably occurred, was observed for the cold beverage bottle near 100°C, but was

not observed for the hot beverage bottle. In the second run, given the same thermal history, almost no differences were observed between

the samples. Based on these results, presumably the hot beverage PET bottle has higher crystallization due to a difference in thermal history

experienced during molding. Separate X-ray diffraction analysis results also confirm that the hot beverage bottle has higher crystallization.

Evaluation of Raw Materials

Product Evaluation

DSC Measurement Results of PET Bottles

Product Information Crystallization of PEEK

This example investigates the relationship between the thermal history of PEEK and its crystallization. The figure below shows that when PEEK

film was heated, the glass transition occurred at 145°C, crystallization at 181°C, and melting at 342°C, which indicates it was not crystallized

before heating. In contrast, only a melting point of 339°C was measured for the PEEK pellets, which indicates it was already crystallized

before heating. This difference in crystallization probably occurred due to the rapid cooling experienced by the film sample during molding,

whereas the pellet sample cooled more slowly. This is consistent with DSC measurement results of pellets that were rapidly cooled after the

DSC measurement above, which showed the same glass transition, crystallization, and melting temperatures as the film.

DSC Measurement Results of PEEK

24 LAAN-D-XX026