Page 44 - Pharmaceutical- Guide to Biopharmaceutical

P. 44

Quality Control

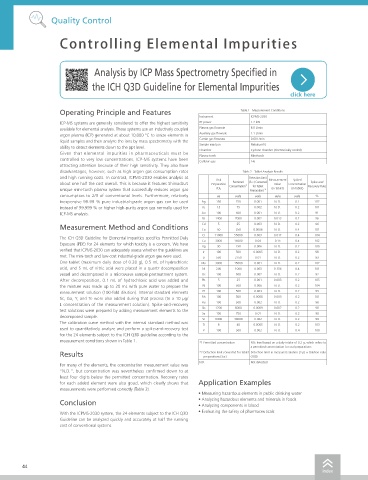

Controlling Elemental Impurities ICPMS-2030

Analysis by ICP Mass Spectrometry Specified in benefits

the ICH Q3D Guideline for Elemental Impurities Cell Line Optimization

click here • Using Shimadzu’s unique mini-torch plasma system, samples can be measured at half

the running cost of previous systems.

Operating Principle and Features Table 1 Measurement Conditions

Instrument ICPMS-2030 • The collision cell offers high sensitivity and low interference to enable simultaneous

ICP-MS systems are generally considered to offer the highest sensitivity RF power 1.2 kW measurement of all target elements evaluated.

available for elemental analysis. These systems use an inductively coupled Plasma gas flowrate 8.0 L/min

argon plasma (ICP) generated at about 10,000 °C to ionize elements in Auxiliary gas flowrate 1.1 L/min • If the Development and Diagnosis Assistant functions, an industry first, are used, Culture

liquid samples and then analyze the ions by mass spectrometry with the Carrier gas flowrate 0.60 L/min data can be analyzed in one tenth the time required previously. (Click here for the

Sample injection

Nebulizer10

ability to detect elements down to the ppt level. Chamber Cyclone chamber (electronically cooled)

Given that elemental impurities in pharmaceuticals must be Plasma torch Mini-torch assistant functions.)

controlled to very low concentrations, ICP-MS systems have been Collision gas He

attracting attention because of their high sensitivity. They also have

disadvantages, however, such as high argon gas consumption rates Table 2 Tablet Analysis Results

and high running costs. In contrast, ICPMS-2030 enables analysis at Oral Detection Limit Measurement Spiked

Spike and

Permitted

about one half the cost overall. This is because it features Shimadzu’s Preparation Concentration *1 (3 σ) Converted Value Concentration Recovery Rate

for Tablet

unique mini-torch plasma system that successfully reduces argon gas PDE Preparations *2 (in tablet) (in tablet)

consumption to 2/3 of conventional levels. Furthermore, relatively µg µg/g µg/g µg/g µg/g % Purification

inexpensive 99.99 % pure industrial-grade argon gas can be used Ag 150 750 0.001 N. D. 0.1 107

instead of 99.999 % or higher high-purity argon gas normally used for As 15 75 0.002 N. D. 0.2 101

ICP-MS analysis. Au 100 500 0.001 N. D. 0.2 91

Ba 1400 7000 0.002 0.013 0.2 96

96

0.003

25

Measurement Method and Conditions Cd 50 5 250 0.0006 N. D. 0.2 101

Co

0.4

N. D.

Cr 11000 55000 0.003 0.017 0.4 104

The ICH Q3D Guideline for Elemental Impurities specifies Permitted Daily Cu 3000 15000 0.04 0.15 0.4 102

Exposure (PDE) for 24 elements for which toxicity is a concern. We have Hg 30 150 0.006 N. D. 0.2 100

verified that ICPMS-2030 can adequately assess whether the guidelines are Ir 100 500 0.0005 N. D. 0.2 98

met. The mini-torch and low-cost industrial-grade argon gas were used. Li 550 2750 0.01 N. D. 0.2 93

One tablet (maximum daily dose of 0.20 g), 0.5 mL of hydrochloric Mo 3000 15000 0.001 N. D. 0.2 107 Characterization

acid, and 5 mL of nitric acid were placed in a quartz decomposition Ni 200 1000 0.003 0.156 0.4 101

vessel and decomposed in a microwave sample pretreatment system. Os 100 500 0.007 N. D. 0.2 92

After decomposition, 0.1 mL of hydrochloric acid was added and Pb 5 25 0.001 0.003 0.2 105

the mixture was made up to 20 mL with pure water to prepare the Pd 100 500 0.006 N. D. 0.2 104

measurement solution (100-fold dilution). Internal standard elements Pt 100 500 0.003 N. D. 0.2 99

Sc, Ga, Y, and Te were also added during that process (to a 10 μg/ Rh 100 500 0.0008 0.003 0.2 101 Specifications

0.002

100

500

N. D.

L concentration of the measurement solution). Spike-and-recovery Ru 1200 6000 0.0009 0.007 0.2 98

Sb

98

0.2

test solutions were prepared by adding measurement elements to the Se 150 750 0.01 N. D. 0.2 98 Instrument: ICPMS-2030

decomposed sample. Sn 6000 30000 0.002 N. D. 0.2 98 Quality Control

The calibration curve method with the internal standard method was Tl 8 40 0.0005 N. D. 0.2 103 Plasma ion source unit Spray chamber: Cyclone chamber (Thermoelectric cooling type)

used to quantitatively analyze and perform a spike-and-recovery test V 100 500 0.002 N. D. 0.4 100 Peristaltic pump: 4-channel

for the 24 elements subject to the ICH Q3D guideline according to the

measurement conditions shown in Table 1. *1 Permitted concentration PDE level based on a daily intake of 0.2 g, which refers to Plasma torch: Mini-torch plasma system

a permitted concentration for oral preparations Nebulizer: Coaxial

Results *2 Detection limit converted for tablet Detection limit in measured solution (3 σ) × Dilution ratio Torch position adjustment: X, Y, Z-axes automatic adjustment

(100)

preparations (3 σ)

N.D. Not detected

For many of the elements, the concentration measurement value was RF power supply unit Frequency: 27 MHz

“N.D.”, but concentration was nevertheless confirmed down to at High-frequency output: Max. 1.4 kW ± 0.3 %

least four digits below the permitted concentration. Recovery rates Pharmacokinetics

for each added element were also good, which clearly shows that Application Examples Mass spectrometer unit Mass analyzer: Quadruple type mass spectrometer

measurements were performed correctly (Table 2). Mass range: 5 to 260

• Measuring hazardous elements in public drinking water Collision cell: Octopole collision cell

Conclusion • Analyzing hazardous elements and minerals in foods Helium gas 0 to 10 mL/min

• Analyzing components in blood

With the ICPMS-2030 system, the 24 elements subject to the ICH Q3D • Evaluating the safety of pharmaceuticals Detector: Electron multiplier

Guideline can be analyzed quickly and accurately at half the running Exhaust system: 3-stage operation exhaust

cost of conventional systems. Others

Dimensions: W 870 mm × D 645 mm × H 587 mm

(excluding protrusion)

Weight: 145 kg

44 45

index index