Page 12 - Shimadzu’s Solutions for Impurities Analysis

P. 12

FDA Regulations on

Quantitation of Ultra-trace Impurities

Genotoxic Impurities

Co-Sense for Impurities

˙ Quantitation of Ultra-trace Impurities Using the Co-Sense for

Impurities System

High-sensitivity quantitation of impurities using trap Recommended Approaches." This method can fully exploit

concentration, 2D separation, and an absorbance detector is various separation conditions, such as phosphoric acid buffers

another approach to achieving the quantitation of ultra-trace and ion-pair reagents, to achieve separation and high-sensitivity

impurities required in the FDA draft guidance, "Genotoxic and quantitation of specific ultra-trace impurities. This can be

Carcinogenic Impurities in Drug Substances and Products: achieved by the Shimadzu Co-Sense for Impurities system.

FDA Regulations on

Genotoxic Impurities

˙ The Co-Sense for Impurities Analysis System Features

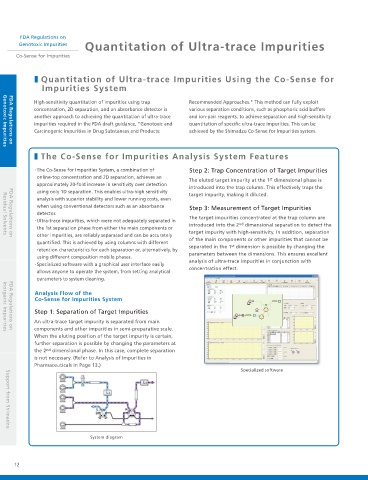

The Co-Sense for Impurities System, a combination of Step 2: Trap Concentration of Target Impurities

online-top concentration and 2D separation, achieves an

st

The eluted target impurity at the 1 dimensional phase is

approximately 20-fold increase in sensitivity over detection

introduced into the trap column. This effectively traps the

using only 1D separation. This enables ultra-high sensitivity

target impurity, making it diluted.

analysis with superior stability and lower running costs, even

when using conventional detectors such as an absorbance Step 3: Measurement of Target Impurities

detector.

The target impurities concentrated at the trap column are

Ultra-trace impurities, which were not adequately separated in

nd

introduced into the 2 dimensional separation to detect the

the 1st separation phase from either the main components or

target impurity with high-sensitivity. In addition, separation

other impurities, are reliably separated and can be accurately

Residual Solvents

of the main components or other impurities that cannot be

FDA Regulations on

quantified. This is achieved by using columns with different

st

separated in the 1 dimension is possible by changing the

retention characteristics for each separation or, alternatively, by

parameters between the dimensions. This ensures excellent

using different composition mobile phases.

analysis of ultra-trace impurities in conjunction with

Specialized software with a graphical user interface easily

concentration effect.

allows anyone to operate the system, from setting analytical

parameters to system cleaning.

Analysis Flow of the

Co-Sense for Impurities System

Step 1: Separation of Target Impurities

An ultra-trace target impurity is separated from main

components and other impurities in semi-preparative scale.

Inorganic Impurities

FDA Regulations on

When the eluting position of the target impurity is certain,

further separation is possible by changing the parameters at

nd

the 2 dimensional phase. In this case, complete separation

is not necessary. (Refer to Analysis of Impurities in

Pharmaceuticals in Page 13.)

Specialized software

Support from Shimadzu

System diagram

12