Page 11 - Electric&Electronics - Total Solution for Analyzing Electronic Devices

P. 11

Observation and Analysis/Evaluation

Elemental Analysis and Contaminant Analysis

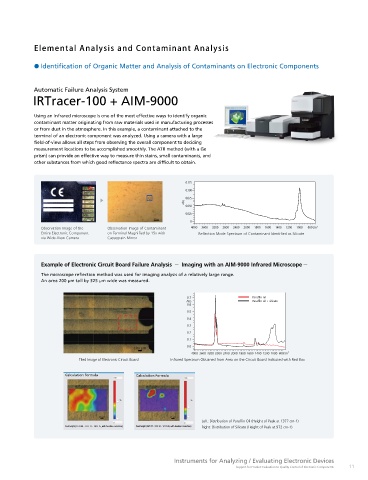

● Non-Destructive 3D Measurement of Plastic Connectors and Other Molded Parts ● Identi cation of Organic Matter and Analysis of Contaminants on Electronic Components

Dimensional X-Ray CT System Automatic Failure Analysis System

XDimensus 300 IRTracer-100 + AIM-9000

The XDimensus 300 is a dimensional X-ray CT system that can Using an infrared microscope is one of the most effective ways to identify organic

measure the 3D internal and external geometry of sample interiors. contaminant matter originating from raw materials used in manufacturing processes

In addition to a high-resolution X-ray detector with a large or from dust in the atmosphere. In this example, a contaminant attached to the

eld-of-view, a new Shimadzu X-ray generator, and new software terminal of an electronic component was analyzed. Using a camera with a large

with outstanding operability, the system features an air conditioning eld-of-view allows all steps from observing the overall component to deciding

system that maintains a constant temperature inside the instrument, measurement locations to be accomplished smoothly. The ATR method (with a Ge

a frame that ensures high geometric stability, and a stage with prism) can provide an effective way to measure thin stains, small contaminants, and

ultra-accurate sample positioning. Those features achieve a other substances from which good re ectance spectra are dif cult to obtain.

dimensional X-ray CT system with the highest measurement accuracy

available in Japan. The XDimensus 300 system can be expected to

help improve operating ef ciency and quality control systems for 0.125

various product inspections or drawing veri cations. 0.100

0.075

Abs

0.050

0.025

Unlike optical coordinate measuring devices, the

XDimensus 300 is unaffected by the color of sample 0

Observation Image of the Observation Image of Contaminant 4000 3600 3200 2800 2400 2000 1800 1600 1400 1200 1000 800cm -1

surfaces. Dimensions can be measured even if sample

Entire Electronic Component on Terminal Magnified by 15x with Reflection Mode Spectrum of Contaminant Identified as Silicate

surfaces are transparent or re ective like a mirror. via Wide-View Camera Cassegrain Mirror

In addition to measuring dimensions, it can compare

shape measurements from two sets of CT data.

Deviations in three-dimensional shapes can be

represented as color-coded maps to compare the Example of Electronic Circuit Board Failure Analysis ̶ Imaging with an AIM-9000 Infrared Microscope ̶

shapes of molded plastic parts and evaluate mold

deterioration over time. The microscope re ection method was used for imaging analysis of a relatively large range.

An area 200 µm tall by 325 µm wide was measured.

0.7 Paraf n oil

Abs Paraf n oil + silicate

0.6

0.5

0.4

0.3

0.2

Surface Data (Simultaneous Scan of Identical Products)

0.1

0.0

4000 3600 3200 2800 2400 2000 1800 1600 1400 1200 1000 800cm -1

Tiled Image of Electronic Circuit Board Infrared Spectrum Obtained from Area on the Circuit Board Indicated with Red Box

Calculation Formula Calculation Formula

Comparison of Shape Measurements in Two Sets of CT Data Left: Distribution of Paraf n Oil (Height of Peak at 1377 cm-1)

Peak height (1330.88 - 1377.17 - 1415.75, with baseline correction) Peak height (867.97 - 972.12 - 1211.30, with baseline correction) Right: Distribution of Silicate (Height of Peak at 972 cm-1)

10 11