Page 35 - Shimadzu Journal vol.9 Issue2

P. 35

Latest topics 2

HYDROX 3D Nanofiber Enables

Three-Dimensional Cell Culturing

In cell research, drug discovery screening, regenerative medicine, Conventional cell culturing is typically performed by two-dimen-

and other fields, there is a need to build cell aggregates outside or- sional “plate culturing,” but the majority of human cells have

ganisms that function similar to the given organism. HYDROX 3D three-dimensional structures. Consequently, three-dimensional cul-

nanofiber* (Fig. 1) is a new material developed independently by turing has gained significant interest in recent years. However,

1

Shimadzu to assist the formation of cell aggregates by three-dimen- the animal-based components used as a scaffold material* for

3

sional cell culturing. In August 2021, Shimadzu collaborated with three-dimensional culturing involve difficulties with reproducibil-

a research group of Osaka University to show that HYDROX na- ity, safety, handling, and manufacturing.

nofibers can be used to efficiently derive hepatocyte-like cells from

human iPS cells by applying hepatic differentiation (reference 1). In 2016, Shimadzu Corporation developed HYDROX 3D nanofiber

That research group is headed by Professor Hiroyuki Mizuguchi from Shimadzu’s own chemically synthesized polymer (HYDROX

and Specially Appointed Assistant Professor Yukiko Toba in the raw material polymer) * (Fig. 2 and reference 2) and determined

4

Laboratory of Biochemistry and Molecular Biology, Graduate that HYDROX can be used to enable easy three-dimensional cul-

School of Pharmaceutical Sciences at Osaka University. turing. The actual culturing steps are illustrated in Fig. 3.

(1) Powdered HYDROX raw material polymer dissolved in solu-

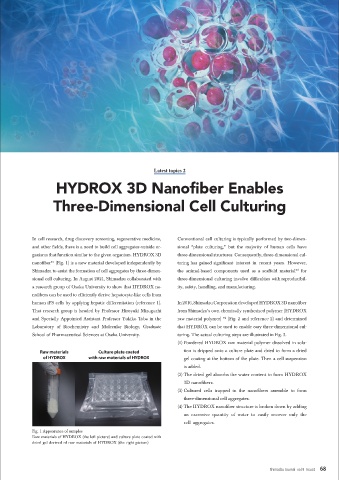

Raw materials Culture plate coated tion is dripped onto a culture plate and dried to form a dried

of HYDROX with raw materials of HYDROX gel coating at the bottom of the plate. Then a cell suspension

is added.

(2) The dried gel absorbs the water content to form HYDROX

3D nanofibers.

(3) Cultured cells trapped in the nanofibers assemble to form

three-dimensional cell aggregates.

(4) The HYDROX nanofiber structure is broken down by adding

an excessive quantity of water to easily recover only the

cell aggregates.

Fig. 1 Appearance of samples

Raw materials of HYDROX (the left picture) and culture plate coated with

dried gel derived of raw materials of HYDROX (the right picture)

Shimadzu Journal vol.9 Issue2 68