Page 43 - Shimadzu Dynamic and Fatigue Testing Systems

P. 43

Actuator

The electromagnetic actuator is coupled with low-friction bearings to achieve high waveform reproducibility.

Electric Crosshead Drive and Manual Clamp Levers

The crosshead can be raised or lowered using an electric switch. The crosshead can be immobilized easily

Load cell

using manual clamp levers. EHF Series Electric Hydraulic Dynamic and Fatigue Testing System

Emergency stop switch

Servo Controller 4830 and Control/Data Analysis Software

The controller allows high-performance and high-functionality dynamic and fatigue testing.

Power Amplifier Unit

Internal electronic power circuits are used to drive the electromagnetic actuator. The top surface can be used

as a table for the controller.

Dual-Stage Crosshead Drive Mechanism

Using two buttons to operate the crosshead and clamps helps prevent operating errors and accidents. Air-cooling unit (inside main unit)

Specifications EMT/NJ-SERVO/MMT Series Electric Fatigue and Endurance Test System

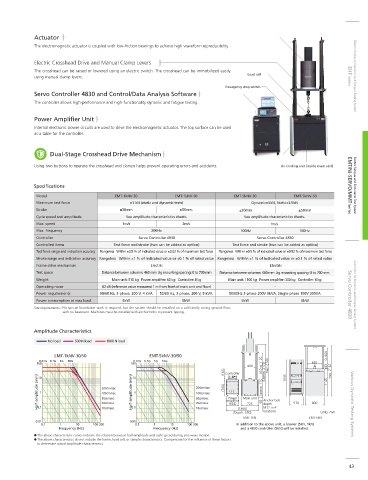

Model EMT-1kNV-30 EMT-1kNV-50 EMT-5kNV-30 EMT-5kNV-50

Maximum test force ±1 kN (static and dynamic tests) Dynamic±5kN, Static±3.5kN

Stroke ±30mm ±50mm ±30mm ±50mm

Cycle speed and amplitude See amplitude characteristics charts. See amplitude characteristics charts.

Max. speed 1m/s 2m/s 1m/s

Max. frequency 200Hz 100Hz 100Hz

Controller Servo Controller 4830 Servo Controller 4830

Controlled items Test force and stroke (two can be added as option) Test force and stroke (two can be added as option)

Test force range and indication accuracy Rangeless Within ±0.5 % of indicated value or ±0.02 % of maximum test force Rangeless Within ±0.5 % of indicated value or ±0.02 % of maximum test force

Stroke range and indication accuracy Rangeless Within ±1 % of indicated value or ±0.1 % of rated value Rangeless Within ±1 % of indicated value or ±0.1 % of rated value

Frame drive mechanism Electric Electric

Test space Distance between columns: 460 mm Jig mounting spacing: 0 to 700 mm Distance between columns: 460 mm Jig mounting spacing: 0 to 700 mm

Weight Main unit: 510 kg Power amplifier: 60 kg Controller: 8 kg Main unit: 1100 kg Power amplifier: 300 kg Controller: 8 kg

Operating noise 62 dB (reference value measured 1 m from front of main unit and floor) -

Power requirements 50/60 Hz, 3-phase, 200 V, 4 kVA 50/60 Hz, 3-phase, 200 V, 5 kVA 50/60Hz 3-phase 200V 9kVA, Single-phase 100V 300VA Servo Controller 4830 Controller for Dynamic and Fatigue Testing Systems

Power consumption at max load 4kW 5kW 5kW 6kW

Site requirements : No special foundation work is required, but the system should be installed on a suf ciently strong ground oor,

with no basement. Machines must be installed with anchor bolts to prevent tipping.

Amplitude Characteristics

No load 500 N load 1000 N load

EMT-1kNV-30/50 EMT-5kNV-30/50 0~900

0.01G 0.1G 1G 10G 0.01G 0.1G 1G 10G

100 100 620

460 410 to 1120 max. 2700 183

(165) Controller Approx. 2170 1535 1145 max. 2142

Half-amplitude (mm) 1 200cm/sec Half-amplitude (mm) 1 200cm/sec (700) ampli er Main unit Approx. 710 65 Anchor bolt

10

10

100cm/sec

100cm/sec

Power

50cm/sec

50cm/sec

20cm/sec

20cm/sec

725

(524)

M12 in 4

0.1

0.1

(1360)

10cm/sec

10cm/sec

locations

(Depth: 650) depth 570 800 Units: mm Various Dynamic Testing Systems

EMT-1kN EMT-5kN

0.01 0.01

0.1 1 10 100 200 0.1 1 10 100 200 In addition to the above unit, a blower (5kN, 1kN)

Frequency (Hz) Frequency (Hz) and a 4830 controller (5kN) will be installed.

The above characteristic curves indicate the relation between half-amplitude and cycle speed during sine wave motion.

The above characteristics do not include the frame, load cell, or sample characteristics. Compensate for the in uence of these factors

to determine actual amplitude characteristics.

43