Page 13 - Shimadzu SALD-7500nano

P. 13

Specifications

Hardware Software

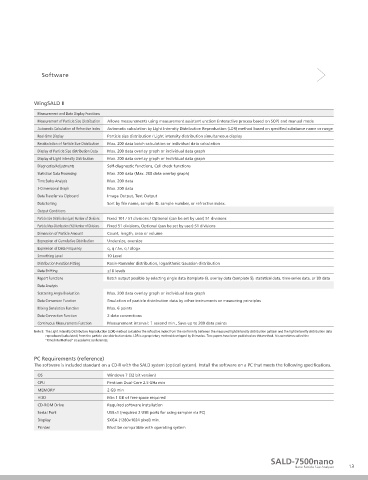

General Specifications WingSALD II

Measurement principle Laser Diffraction Method Measurement and Data Display Functions

Measurement range 7 nm (0.007 µm) to 800 µm (when using sampler) Measurement of Particle Size Distribution Allows measurements using measurement assistant unction (interactive process based on SOP) and manual mode

7 nm (0.007 µm) to 400 µm (when using batch cell) Automatic Calculation of Refractive Index Automatic calculation by Light Intensity Distribution Reproduction (LDR) method based on specified substance name or range

30 nm (0.03 µm) to 280 µm (when using high-concentration sample unit) Real-time Display Particle size distribution / Light intensity distribution simultaneous display

Note 1: The measurement range varies according to the shape etc. of the particle. Recalculation of Particle Size Distribution Max. 200 data batch calculation or individual data calculation

Display of Particle Size distribution Data Max. 200 data overlay graph or individual data graph

Measurement unit: SALD-7500nano (P/N 347-61710-42 [115V], 347-61710-44 [230V]) Display of Light Intensity Distribution Max. 200 data overlay graph or individual data graph

Diagnostics/Adjustments Self-diagnostic functions, Cell check functions

Light source Semiconductor laser (Wavelength 405 nm) Statistical Data Processing Max. 200 data (Max. 200 data overlay graph)

Light detector Detector elements for violet semiconductor laser Total 84 elements (78 forward, 1 side, 5 back) Time Series Analysis Max. 200 data

System compliance Class 1 Laser Product, CE

3-Dimensional Graph Max. 200 data

Required power supply AC 100 V±10 %, 1 A, 50/60 Hz Data Transfer via Clipboard Image Output, Text Output

Dimensions & weight Approx. W680 × D280 × H430 mm, Approx. 32 kg

Data Sorting Sort by file name, sample ID, sample number, or refractive index.

Operation environment Temperature: 10 to 30 °C , Humidity: 20 to 80 % (no condensation) Output Conditions

Note 2: Reference sample and USB cable (2 m) supplied as standard Particle Size Distribution (µm) Number of Divisions Fixed 101 / 51 divisions / Optional (can be set by user) 51 divisions

Note 3: Ultrasonic cleaning instruments are needed for the measurement of reference sample.

Particle Mass Distribution (%) Number of Divisions Fixed 51 divisions, Optional (can be set by user) 51 divisions

Dimension of Particle Amount Count, length, area or volume

Sampler: SALD-MS75 (P/N 347-61711-42 [115V], 347-61711-44 [230V]) Expression of Cumulative Distribution Undersize, oversize

Dispersing bath Capacity: 100 / 200 / 300 mL Expression of Data Frequency q, q / ∆×, q / ∆log×

Sonicator Frequency: about32 kHz, output: about 40 W Smoothing Level 10 Level

Liquid pump Radial pump, maximum flow rate 2000 cm /min Distribution Function Fitting Rosin-Rammler distribution, logarithmic Gaussian distribution

3

Liquid pump material Stainless (SUS 304, SUS 316), Tetrafluoroethylene (PTFE), Perfluoroelastmor (FEP) Data Shifting ±10 levels

Liquid supply pump Diaphragm pump, maximum flow rate: 750 cm /min Report Functions Batch output possible by selecting single data (template 6), overlay data (template 5), statistical data, time-series data, or 3D data

3

Liquid supply pump material Polypropylene Data Analysis

Flow cell Quartz glass Scattering Angle Evaluation Max. 200 data overlay graph or individual data graph

Required power supply AC 100 V±10 %, 2 A, 50/60 Hz Data Conversion Function Emulation of particle distribution data by other instruments or measuring principles

Dimensions & weight Approx. W390 × D520 × H430 mm, Approx.18 kg Mixing Simulation Function Max. 6 points

Operating environment Temperature: 10 to 30 °C, Humidity: 20 to 80 % (no condensation) Data Connection Function 2 data connections

Note 4: USB cable (2 m) supplied as standard Continuous Measurements Function Measurement interval: 1 second min., Save up to 200 data points

Note 5: The Light Intensity Distribution Reproduction (LDR) method calculates the refractive index from the conformity between the measured light intensity distribution pattern and the light intensity distribution data

reproduced (calculated) from the particle size distribution data. LDR is a proprietary method developed by Shimadzu. Two papers have been published on this method. It is sometimes called the

Batch Cell: SALD-BC75 (P/N 347-61712-42) "Kinoshita Method" at academic conferences.

Cell material Quartz glass

Required liquid volume Approx. 5 cm 3 PC Requirements (reference)

Stirrer mechanism Up-and-down movement of blade The software is included standard on a CD-R with the SALD system (optical system). Install the software on a PC that meets the following specifications.

Dimensions & weight Approx. W100 × D120 × H140 mm, Approx. 0.8 kg OS Windows 7 (32 bit version)

Operating environment Temperature: 10 to 30 °C, Humidity: 20 to 80 % (no condensation)

CPU Pentium Dual-Core 2.5 GHz min

MEMORY 2 GB min

High-concentration Measurement Unit: SALD-HC75 (P/N 347-61713-42) HDD Min 1 GB of free space required

CD-ROM Drive Required software installation

Cell material Borosilicate glass

Serial Port USB×1 (required 2 USB ports for using sampler via PC)

Required liquid volume Approx. 0.15 cm 3

Display SXGA (1280×1024 pixel) min.

Dimensions & weight Approx. W20 × D100 × H9 mm, Approx. 0.2 kg

Printer Must be compatible with operating system

Operating environment Temperature: 10 to 30 °C, Humidity: 20 to 80 % (no condensation)

SALD-7500nano

12 Nano Particle Size Analyzer 13