Page 14 - Shimadzu SALD-7500nano

P. 14

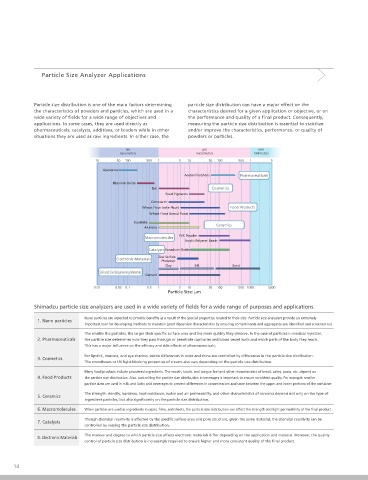

Particle Size Analyzer Applications Measurement Technology: Laser Diffraction Method – Measurement principle of SALD-7500nano –

Particle size distribution is one of the main factors determining particle size distribution can have a major effect on the There is a one-to-one correspondence between the particle diameter and the light intensity distribution pattern.

the characteristics of powders and particles, which are used in a characteristics desired for a given application or objective, or on When a particle is irradiated with a laser beam, light is emitted from the

wide variety of fields for a wide range of objectives and the performance and quality of a final product. Consequently, particle in every direction. This is “scattered light”. The intensity of the (Side) Scattered 1.0 µm

light

applications. In some cases, they are used directly as measuring the particle size distribution is essential to stabilize scattered light varies with the scattering angle and describes a spatial Scattering

pharmaceuticals, catalysts, additives, or binders while in other and/or improve the characteristics, performance, or quality of intensity distribution pattern, known as the “light intensity distribution angle

situations they are used as raw ingredients. In either case, the powders or particles. pattern”. If the particle diameter is large, the scattered light emitted (Back) Laser light (Forward)

from the particle isconcentrated in the forward direction (i.e., the Particle 0.5 µm

direction of the laser beam), and fluctuates intensely in an angular range

nm µm mm

nanometers micrometers millimeters too small to be represented in a diagram. Compared to the light emitted (Side)

in the forward direction, the intensity of all other light is extremely low.

10 5 0 1 0 0 5 0 0 1 5 1 0 5 0 1 0 0 500 1 5 Diffraction / Scattering by Particle

As the particle diameter becomes smaller, the pattern of the scattered 0.3

Liposomes light spreads outwards. As the particle becomes even smaller, the µm

Acetaminophens Pharmaceuticals intensity of the light emitted to the side and backwards becomes higher. The light intensity distribution pattern

becomes gourd-shaped and spreads out in every direction. Therefore, there is exists a one-to-one correspondence

Titanium Oxide between the particle diameter and the light intensity distribution pattern. This means that the particle diameter can

Talc Cosmetics

be ascertained by detecting the light intensity distribution pattern. 0.2 µm

Pearl Pigments

Cornstarch Violet Laser Allows Accurate Measurements of Ultra-Small Particles.

Wheat Flour (cake flour) Food Products

The light intensity distribution pattern varies little relative to the particle size distribution when the particle size

Wheat Flour (bread flour) 0.1 µm

drops to several tens of nanometers. This is the reason for the minimum limit of detection of the laser diffraction

Kaolinite Ceramics method. A violet laser creates clearer differences in the light intensity distribution pattern at ultra-small particle sizes

Alumina than a red laser. Consequently, a violet laser is used to enhance the measurement performance for ultrafine particles

of the order of several tens of nanometers.

PVC Powder

Macromolecules 0.05 µm

0.05 µm

Acrylic Polymer Beads

Measurement is performed on particle groups.

Catalysts Vanadium Oxide

Particle size distribution measurement is not performed on individual particles, but rather on particle groups made up

Zinc Sulfide

Electronic Materials of a large number of particles. Particle groups contain particles of different sizes, and the light intensity distribution

Phosphor Relationship between

a l C y t l i S S a n d pattern emitted by a group is composed of all the scattered light emitted from all the individual particles. The particle particle diameter

Soil and Civil Engineering Materials size distribution, in other words, what particle sizes are present in what proportions, can be obtained by detecting and Light Intensity

Cement and analyzing this light intensity distribution pattern. This is the basic principle behind the laser diffraction method. Distribution pattern

0.01 0.05 0.1 0.5 1 5 10 50 100 500 1000 5000

Particle Size: µm Forward diffracted/

scattered light

sensor: Wing sensor ll Optical System in SALD-7500nano

Particle

Shimadzu particle size analyzers are used in a wide variety of fields for a wide range of purposes and applications. group The laser beam emitted from the light source (semiconductor laser) is converted into a thick

beam with a collimator and this is directed at the particle group. The scattered light emitted

Nano particles are expected to provide benefits as a result of the special properties related to their size. Particle size analyzers provide an extremely Diffracted/scattered light from the group in a forward direction at up to a 60° angle is concentrated with a lens, and

1. Nano particles Collimator Diffraction/ concentric scattering images are formed at a detecting plane positioned at a distance equal to

important tool for developing methods to maintain good dispersion characteristics by ensuring contaminants and aggregates are identified and screened out. scattering image

the focal length. This is detected with the Wing sensor ll in which light-receiving elements are

The smaller the particles, the larger their specific surface area and the more quickly they dissolve. In the case of particles in medical injection, arranged concentrically. The scattered light emitted to the side and backwards is detected with

Condenser lens

2. Pharmaceuticals the particle size determines how they pass through or penetrate capillaries and blood vessel walls and which parts of the body they reach. side and back scattered light sensors. The light intensity distribution data can be obtained by

This has a major influence on the efficacy and side effects of pharmaceuticals. Violet Semiconductor laser Side/back scattered light sensors detecting scattered light data of all directions.

For lipstick, mascara, and eye shadow, subtle differences in color and shine are controlled by differences in the particle size distribution. Optical system in SALD-7500nano

3. Cosmetics

The smoothness or UV light-blocking properties of creams also vary depending on the particle size distribution.

Back scattered light sensors

Many food products include powdered ingredients. The mouth, tooth, and tongue feel and other characteristics of bread, cakes, pasta, etc. depend on Side scattered light sensors Flow of Light Intensity Detection and Data Processing

4. Food Products the particle size distribution. Also, controlling the particle size distribution in beverages is important to ensure consistent quality. For example, smaller

Detection

Wing sensors ll With the SALD-7500nano, particle size distributions are calculated using the light intensity

particle sizes are used in milk and lactic acid beverages to prevent differences in concentration and taste between the upper and lower portions of the container.

Light Intensity Distribution Pattern distribution data.

The strength, density, hardness, heat resistance, water and air permeability, and other characteristics of ceramics depend not only on the type of The overall flow of detection and data processing is shown in the diagram to the left. The

5. Ceramics whole range of operations from the detection of scattered light intensity distribution patterns

ingredient particles, but also significantly on the particle size distribution. to the calculation of the particle size distribution is executed as one process, and the particle

Light Intensity Distribution Date Light Intensity

6. Macromolecules When particles are used as ingredients in pipes, films, and sheets, the particle size distribution can affect the strength and light permeability of the final product. size distribution data is output.

Sencor Erement Number Recalculation of particle size distributions can be performed by using the previously detected

Calculation of the

Though chemical reactivity is affected by the specific surface area and pore structure, given the same material, the chemical reactivity can be particle size distribution and saved light intensity distribution data and selecting a refractive index that is different from

7. Catalysts

controlled by varying the particle size distribution. the time of measurement.

Particle size distribution data Narmalized Particle Amount

The manner and degree to which particle size affects electronic materials differ depending on the application and material. However, the quality

8. Electronic Materials

control of particle size distribution is increasingly required to ensure higher and more consistent quality of the final product. Particle Diameter (µm)

SALD-7500nano

14 Nano Particle Size Analyzer 15