Page 12 - Shimadzu Nexera XS inert

P. 12

Nexera Series Features for Auto-Diagnostics and Recovery

Assisting Analytical Operations In rare cases, air bubbles can form in the mobile phase and cause problems if inhaled into the pump. Nexera has the

ability to monitor baseline changes and pressure fluctuations to check for abnormalities. When it detects an unusual

fluctuation, it can automatically pause the analysis, purge the flow path, and restart analysis once it has confirmed

The same outstanding instrument performance capabilities offered by Nexera series systems are also available in recovery to normal pressure.

Nexera XS inert systems. For a more advanced analysis, Nexera XS inert can be used with Analytical Intelligence

Pressure

technology for automatic analysis.

Auto-Diagnostics for

Trapped Bubbles (patented) Fluctuation detected

If an air bubble becomes trapped in the pump Normal analysis Auto-purge Resume analysis

once stable

Stable Baseline head, it causes an abrupt drop in pressure, after

which periodic pressure changes (pulsations) will

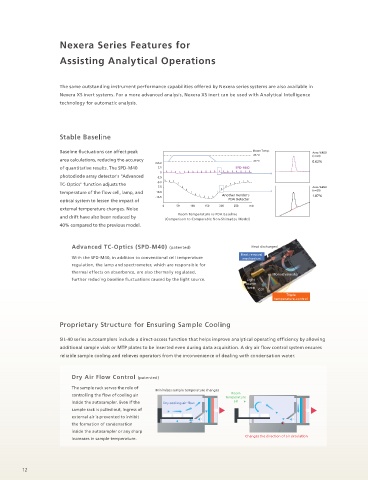

Baseline fluctuations can affect peak Room Temp. Area %RSD occur. This can be detected using Shimadzu's

25 °C (n=20) proprietary bubble detection algorithm which

area calculations, reducing the accuracy 20 °C 0.62% Sample 1 Sample 2 Sample 2

mAU assesses these distinctive pressure fluctuations (Failure) (Retry)

of quantitative results. The SPD-M40 2.5 SPD-M40

0 caused by trapped bubbles to distinguish them

photodiode array detector's "Advanced -2.5 from any expected changes in pressure.

TC-Optics" function adjusts the -5.0

-7.5 Area %RSD

temperature of the flow cell, lamp, and -10.0 Another Vender’s (n=20)

-12.5 1.87%

optical system to lessen the impact of PDA Detector

0 50 100 150 200 250 min

external temperature changes. Noise Mobile Phase Levels Measured in Real Time

Room Temperature vs PDA Baseline

and drift have also been reduced by

(Comparison to Comparable Non-Shimadzu Model)

40% compared to the previous model. Reservoir tray weight sensors (optional) can be used to monitor the volume of the mobile phase or autosampler rinse

solution in up to twelve* containers. The containers can also be checked remotely from a smart device. You will no

longer need to worry about running out of mobile phase mid-analysis, because the device will notify you before

Advanced TC-Optics (SPD-M40) (patented) Heat discharged starting the run if the volume remaining is too low.

Heat removal

With the SPD-M40, in addition to conventional cell temperature mechanism *Up to 12 solutions can be monitored using 1-liter containers or up to 4 solutions using larger containers (2-liter or up to 5-liter containers).

regulation, the lamp and spectrometer, which are responsible for

thermal effects on absorbance, are also thermally regulated,

Monochromator

further reducing baseline fluctuations caused by the light source. Light Comparing Solvent Volume Measurements with Predicted Consumption (patented)

source

lamp Cell

Triple The required mobile phase volume is predicted at the start of analysis from the weight sensor's measurement data, the

temperature-control instrument configuration information (the mobile phase used and the rinsing liquid configuration), and the analysis

method. If a shortage is expected, the user will be notified.

Proprietary Structure for Ensuring Sample Cooling

SIL-40 series autosamplers include a direct-access function that helps improve analytical operating efficiency by allowing

additional sample vials or MTP plates to be inserted even during data acquisition. A dry air flow control system ensures

reliable sample cooling and relieves operators from the inconvenience of dealing with condensation water.

Dry Air Flow Control (patented)

The sample rack serves the role of

Minimizes sample temperature changes

Room

controlling the flow of cooling air temperature

inside the autosampler. Even if the Dry cooling air flow air Monitoring Levels Even from Outside the Laboratory

sample rack is pulled out, ingress of

external air is prevented to inhibit • Automated support functions utilizing digital technologies, such as M2M, IoT, and Artificial Intelligence (AI),

that enable higher productivity and maximum reliability.

the formation of condensation

• Allows a system to monitor and diagnose itself, handle any issues during data acquisition without user input,

inside the autosampler or any sharp and automatically behave as if it were operated by an expert.

Changes the direction of air circulation

increases in sample temperature. • Supports the acquisition of high quality, reproducible data regardless of an operator's skill level for both

routine and demanding applications.

12 13