Page 25 - Shimadzu Journal vol.10 Issue1

P. 25

Materials Science

All-Solid-State Lithium-Ion Batteries

and Related Issues

Fig. 2 is a schematic of an all-solid-state lithium-ion battery (hereaf-

ter: All-solid-state LiB). All-solid-state LiBs use a solid electrolyte,

so they are safer than LiBs that use a normal combustible liquid

electrolyte. However, the contact between the solid electrolyte

and the electrodes is poor, so the interface’s electrical resistance is

large, making high-speed charging and discharging difficult. The (a) ZXY Data (b) LCO Height Image

SPM can measure the distribution of current and electric forces at Fig. 4. LCO ZXY Data and Constructed Height Image

the microscopic scale, so it holds promise as one method for evalu-

ating the interface between solid electrolytes and electrodes.

In this article, sintered compacts of commercially available Table 1 Measurement Conditions

electrode material were observed and measured, in anticipation of Instrument: Scanning Probe Microscope SPM-8100FM

Deep type scanner

the analysis of electrodes in contact with a solid electrolyte. The Scanner: (maximum operation range XY: 55 μm, Z: 13 μm)

materials used were lithium cobaltite (LiCoO : hereafter LCO) for Holder: Micro current holder Measurement range: ±10 nA

2

the cathode and lithium titanate (Li Ti O : hereafter LTO), both of Observation Mode: ZXY measurement

4 5 12

which are used in all-solid-state LiBs. Fig. 3 shows an overview of Pixel Number: Z: 1024 X: 256 Y: 256

the observations. Note that the electrode material used here was in Purge Gas: Argon

its initial state, beforechargingor discharging. Atmosphere: Oxygen 0.7 ppm or less, water vapor 0.75 ppm or less

Image Construction and Inspection

The images in Fig. 5 (a) to (j) were constructed from ZXY data in

the measurement range from XY: 30 µm Z: 12 µm to XY: 5 µm

Z: 6 µm.

(1) Height Images

The 30 µm LCO height image (a) and the 30 µm LTO height image

(c) showed irregularities on the order of 2 µm, and the roughness

(Sa) analysis showed surface roughness at 341.5 nm and 333.6 nm.

Several gaps in the LCO were also found. In contrast, no gaps were

Fig. 2. Schematic Diagram of Fig. 3. Observation of a Sintered

All-Solid-State LiB Compact of Commercially Available found in the LTO, but residual marks from sample formation were

Electrode Material evident on the samples in the vertical direction.

The 5 µm LCO height image (e) showed that the grains in the

electrode material were about 1 µm in size, and that there were

small gaps between them. There were also grains several hundred

ZXY Current Measurements nm in size as indicated by the arrows. The LTO height image (h)

and Image Construction showed plate-like crystal structures as indicated by the arrows.

(2) Current Images

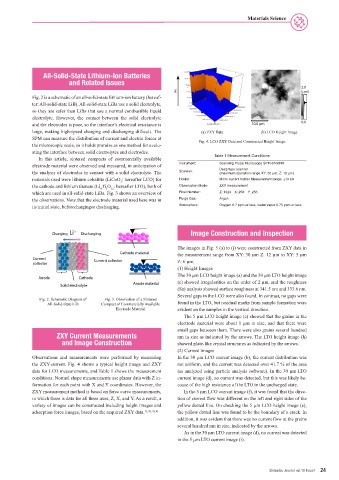

Observations and measurements were performed by measuring In the 30 µm LCO current image (b), the current distribution was

the ZXY-current. Fig. 4 shows a typical height image and ZXY not uniform, and the current was detected over 41.7 % of the area

data for LCO measurements, and Table 1 shows the measurement (as analyzed using particle analysis software). In the 30 µm LTO

conditions. Normal shape measurements use planar data with Z in- current image (d), no current was detected, but this was likely be-

formation for each point with X and Y coordinates. However, the cause of the high resistance of the LTO in the uncharged state.

ZXY measurement method is based on force curve measurements, In the 5 µm LCO current image (f), it was found that the direc-

in which there is data for all three axes, Z, X, and Y. As a result, a tion of current flow was different on the left and right sides of the

variety of images can be constructed including height images and yellow dotted line. On checking the 5 µm LCO height image (e),

adsorption force images, based on the acquired ZXY data. 1), 2), 3), 4) the yellow dotted line was found to be the boundary of a crack. In

addition, it was evident that there was no current flow at the grains

several hundred nm in size, indicated by the arrows.

As in the 30 µm LTO current image (d), no current was detected

in the 5 µm LTO current image (i).

Shimadzu Journal vol.10 Issue1 24