Page 13 - Shimadzu Autograph AGS-X Series

P. 13

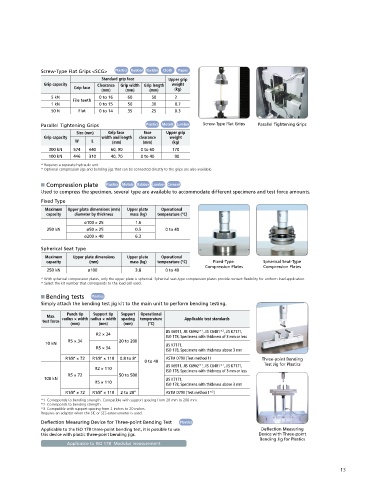

Screw-Type Flat Grips <SCG> Plastics Rubber Textiles Cloth Paper

Standard grip face Upper grip

Grip capacity Clearance Grip width Grip length weight

Grip face

(mm) (mm) (mm) (kg)

5 kN 0 to 16 60 50 2

File teeth

1 kN 0 to 15 50 30 0.7

50 N Flat 0 to 14 35 25 0.3

Parallel Tightening Grips Plastics Metals Lumber Screw-Type Flat Grips Parallel Tightening Grips

Size (mm) Grip face Face Upper grip

Grip capacity width and length clearance weight

W L (mm) (mm) (kg)

300 kN 574 440 60, 90 0 to 60 170

100 kN 446 310 40, 70 0 to 40 90

* Requires a separate hydraulic unit

* Optional compression jigs and bending jigs that can be connected directly to the grips are also available.

Compression plate Plastics Metals Rubber Lumber Cement

Used to compress the specimen, several type are available to accommodate different specimens and test force amounts.

Fixed Type

Maximum Upper plate dimensions (mm) Upper plate Operational

capacity diameter by thickness mass (kg) temperature (°C)

ø100 × 25 1.6

250 kN ø50 × 25 0.5 0 to 40

ø200 × 40 6.3

Spherical Seat Type

Maximum Upper plate dimensions Upper plate Operational

capacity (mm) mass (kg) temperature (°C) Fixed-Type Spherical Seat-Type

Compression Plates Compression Plates

250 kN ø100 3.8 0 to 40

* With spherical compression plates, only the upper plate is spherical. Spherical seat-type compression plates provide contact exibility for uniform load application.

* Select the kit number that corresponds to the load cell used.

Bending tests Plastics

Simply attach the bending test jig kit to the main unit to perform bending testing.

Punch tip Support tip Support Operational

Max.

test force radius × width radius × width spacing temperature Applicable test standards

(mm) (mm) (mm) (°C)

1

JIS K6911, JIS K6902* , JIS C6481* , JIS K7171,

2

R2 × 34

ISO 178, Specimens with thickness of 3 mm or less

R5 × 34 20 to 200

10 kN JIS K7171,

R5 × 34 ISO 178, Specimens with thickness above 3 mm

R1/8″ × 72 R1/8″ × 110 0.8 to 8″ ASTM D790 (Test method 1) Three-point Bending

0 to 40

1

2

JIS K6911, JIS K6902* , JIS C6481* , JIS K7171, Test Jig for Plastics

R2 × 110 ISO 178, Specimens with thickness of 3 mm or less

R5 × 72 50 to 500

100 kN JIS K7171,

R5 × 110

ISO 178, Specimens with thickness above 3 mm

R1/8″ × 72 R1/8″ × 110 2 to 20″ ASTM D790 (Test method 1* )

3

*1 Corresponds to bending strength. Compatible with support spacing from 20 mm to 200 mm.

*2 Corresponds to bending strength.

*3 Compatible with support spacing from 2 inches to 20 inches.

Requires an adaptor when the SIE or SES extensometer is used.

Deflection Measuring Device for Three-point Bending Test Plastics

Applicable to the ISO 178 three-point bending test, it is possible to use Deflection Measuring

this device with plastic three-point bending jigs. Device with Three-point

Bending Jig for Plastics

Applicable to ISO 178 Modulus measurement

13