Page 18 - Shimadzu Autograph AGS-X Series

P. 18

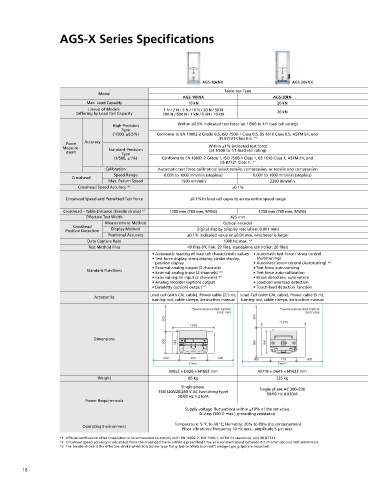

AGS-X Series Specifications

AGS-10kNX AGS-20kNX

Table-top Type

Model

AGS-10kNX AGS-20kN

Max. Load Capacity 10 kN 20 kN

Lineup of Models 1 N / 2 N / 5 N / 10 N / 20 N / 50 N

Differing by Load Cell Capacity 100 N / 500 N / 1 kN / 5 kN / 10 kN 20 kN

High-Precision Within ±0.5% indicated test force (at 1/500 to 1/1 load cell rating)

Type

(1/500, ±0.5%) Conforms to EN 10002-2 Grade 0.5, ISO 7500-1 Class 0.5, BS 1610 Class 0.5, ASTM E4, and

JIS B7721 Class 0.5. * 1

Force Accuracy

Measure- Standard-Precision Within ±1% indicated test force

ment Type (at 1/500 to 1/1 load cell rating)

(1/500, ±1%) Conforms to EN 10002-2 Grade 1, ISO 7500-1 Class 1, BS 1610 Class 1, ASTM E4, and

JIS B7721 Class 1. * 1

Calibration Automatic test force calibration: select tensile, compression, or tensile and compression

Speed Range 0.001 to 1000 mm/min (stepless) 0.001 to 1600 mm/min (stepless)

Crosshead

Max. Return Speed 1500 mm/min 2200 mm/min

Crosshead Speed Accuracy * 2 ±0.1%

Crosshead Speed and Permitted Test Force ±0.1%To load cell capacity across entire speed range

Crosshead – Table Distance (Tensile stroke) * 3 1200 mm (760 mm, MWG) 1250 mm (765 mm, MWG)

Effective Test Width 425 mm

Measurement Method Optical encoder

Crosshead

Position Detection Display Method Digital display (display resolution: 0.001 mm)

Positional Accuracy ±0.1% indicated value or ±0.01 mm, whichever is larger

Data Capture Rate 1000 Hz max. * 4

Test Method Files 40 files (PC link: 20 files, standalone controller: 20 files)

• Automatic reading of load cell characteristic values • Automatic test force / stress control

• Test force display, stress display, stroke display, (Autotuning)

position display • Automatic strain control (Autotuning) * 4

• External analog output (2 channels) • Test force auto-zeroing

Standard Functions

• External analog input (2 channels) * 4 • Test force auto-calibration

• External digital input (2 channels) * 4 • Break detection, auto-return

• Analog recorder (option) output • Load cell overload detection

• Dataletty (option) output * 5 • Touch-load detection function

Accessories Load cell (with CAL cable), Power cable (2.5 m), Load Cell (with CAL cable), Power cable (5 m),

turning rod, cable clamps, instruction manual turning rod, cable clamps, instruction manual

*Special-purpose desk (option) *Special-purpose desk (option)

(Unit: mm) (Unit: mm)

600 600

*1200

* 950

Dimensions

* 500 520 800 641

600 653 600 600 718 600

Front Front

W653 × D520 × H1603 mm W718 × D641 × H1633 mm

Weight 85 kg 235 kg

Single phase

100/120/220/240 V AC (switching type) Single phase AC 200–230

50/60 Hz 4.0 kVA

50/60 Hz 1.2 kVA

Power Requirements

Supply voltage fluctuations within ±10% of the set value.

D-class (100 max.) grounding resistance.

Temperature: 5 °C to 40 °C; Humidity: 20% to 80% (no condensation)

Operating Environment

Floor vibrations: frequency 10 Hz max., amplitude 5 m max.

*1 Of cial certi cation after installation is recommended to comply with EN 10002-2, ISO 7500-1, ASTM E4 standards, and JIS B7721.

*2 Crosshead speed accuracy is calculated from the crosshead travel within a prescribed time at a constant speed between 0.5 mm/minute and 500 mm/minute.

*3 The tensile stroke is the effective stroke when SCG (screw-type at grips) or MWG (non-shift wedge-type grips) are mounted.

18