Page 25 - Shimadzu EDX-8100

P. 25

Small Spot Analysis Kit (Option) Specifications

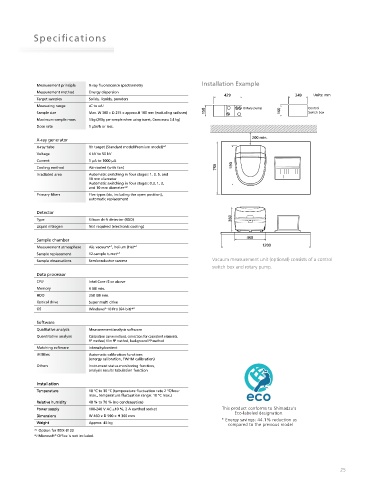

For Analysis of Small Contaminants and Defect Analysis in Small Regions Measurement principle X-ray fluorescence spectrometry Installation Example

Measurement method Energy dispersion

This option can be used to analyze even smaller areas by replacing the collimator plate and sample 429 249 Units: mm

Target samples Solids, liquids, powders

observation camera. It is especially useful for analyzing trace foreign matter and defects in micro areas, Measuring range 6C to 92U

and measuring plating thickness. Sample size Max. W 300 × D 275 × approx.H 100 mm (excluding radiuses) 158 Rotary pump 160 Control

Switch box

Maximum sample mass 5 kg (200g per sample when using turret, Gross mass 2.4 kg)

Minimum 0.3 mm X-Ray Irradiation Diameter Dose rate 1 Sv/h or less.

The excitation X-rays can be collimated to 0.3 mm in diameter, which is effective for the 200 min.

high-accuracy analysis of small contaminants and for defect analysis in small regions, X-ray generator

Sample Image at an Irradiation Diameter X-ray tube Rh target (Standard model/Premium model)* 1

analyses difficult with standard specifications (minimum 1 mm in diameter). of 0.3 mm (Extended Zoom)

Sample: stainless powder (approx. 0.1 mm) Voltage 4 kV to 50 kV

Enlarged Sample Images without Image Quality Degradation collected on filter paper Current 1 A to 1000 A

Cooling method Air-cooled (with fan) 750 590

This system supports smaller samples, which heightens the visibility of sample

Irradiated area Automatic switching in four stages: 1, 3, 5, and

observation images. Users can switch to an enlarged image approximately 2.5 times 10 mm diameter

Irradiation area Automatic switching in four stages: 0.3, 1, 3,

larger than a previous image, without image quality degradation. 0.3 mm in diameter and 10 mm diameter* 2

(yellow circle)

Primary filters Five types (six, including the open position),

Automatic Four-Stage Switching Between 0.3, 1, 3, and 10 mm in Diameter Irradiation area automatic replacement

1 mm in diameter

The irradiation diameter automatically switches between 0.3, 1, 3, and 10 mm in diameter. (green circle)

Detector

This system supports not only the analysis of small spots but also macro composition

Type Silicon drift detector (SDD) 360

analysis at 10 mm in diameter. Liquid nitrogen Not required (electronic cooling)

Note: The irradiation diameter is the size on the sample surface. Metal Plated Terminals

(At 1 mm in diameter, the irradiation area is not

Irradiation diameter Extended zoom button within the measurement area, so measurements 460

switching buttons (Enlargement to approx. Sample chamber

2.5 times the camera image) are impossible. At 0.3 mm in diameter, 1200

1

measurements are possible.) Measurement atmosphere Air, vacuum* , helium (He)* 1

Sample replacement 12-sample turret* 1

PCEDX Navi Sample Image Setting Fields Sample observations Semiconductor camera Vacuum measurement unit (optional) consists of a control

switch box and rotary pump.

Analysis Example—Small Metal Powder (Approx. 0.1 mm in Diameter) Adhered to the Surface of Snacks Data processor

CPU Intel Core i5 or above

A small metal powder approximately 0.1 mm in diameter adhered to the commercially available snacks was analyzed with irradiation diameters

Memory 4 GB min.

of 1 mm and 0.3 mm, respectively. At an irradiation diameter of 1 mm, the overall background is significantly increased due to the influence of

HDD 250 GB min.

scattered X-rays from the surrounding area of the metal powder (snacks), resulting in a poor S/N ratio. At an irradiation diameter of 0.3 mm, Optical drive Super multi drive

however, the influence of scattered X-rays from the surrounding area is small, and peak profiles with a good S/N ratio are obtained. OS Windows 10 Pro (64-bit)* 2

®

Copper (Cu) and Zinc (Zn) are detected as the major components with both irradiation diameters. It indicates that the metal powder is brass

regardless of the irradiation diameter used. However, at 0.3 mm in diameter, the peak of Lead (Pb) is also identified, which suggests that the Software

Qualitative analysis Measurement/analysis software

metal powder is “free cutting brass”.

Quantitative analysis Calibration curve method, correction for coexistent elements,

By using an irradiation diameter of 0.3 mm, more accurate analyses can be performed, even for small contaminants on substances such as FP method, film FP method, background FP method

organic materials that strongly scatter X-rays. Matching software Intensity/content

Utilities Automatic calibration functions

CuKa ø1 mm (energy calibration, FWHM calibration)

ø0.3 mm RhKaC Others Instrument status monitoring function,

analysis results tabulation function

CaKa

ZnKa

ZnKb Installation

Installation

10 °C to 30 °C (temperature fluctuation rate 2 °C/hour

Temperature

Temperature 10 °C to 30 °C (temperature fluctuation rate 2 °C/hour

Sample Image max., temperature fluctuation range: 10 °C max.)

max., temperature fluctuation range: 10 °C max.)

(The yellow circle at the center is 0.3 mm.)

PbLa PbLb1 Relative humidity 40 % to 70 % (no condensation)

40 % to 70 % (no condensation)

Relative humidity

100-240 V AC ±10 %, 2 A earthed socket

Power supply

CuKb RhKa Power supply 100-240 V AC ±10 %, 2 A earthed socket This product conforms to Shimadzu's

Eco-labeled designation.

W 460 × D 590 × H 360 mm

W 460 × D 590 × H 360 mm

Dimensions

Dimensions

CaKb FeKa ZnKb SrKa RhKbC Weight Approx. 45 kgɹ * Energy savings: 44.1% reduction as

Weight

Approx. 45 kgɹ

KKa PbLa PbLb1 RhKb * 1 Option for EDX-8100 compared to the previous model

* 2 Microsoft ® Office is not included.

24 25