Page 8 - Material Characterizations

P. 8

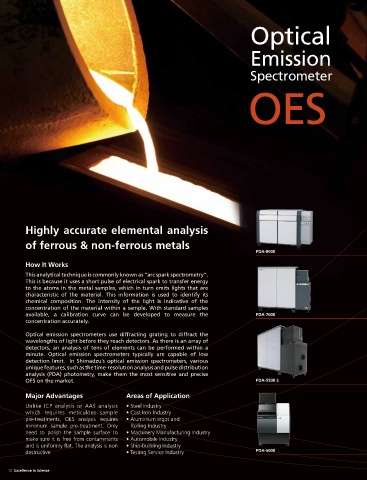

Optical

Emission

Spectrometer

OES

Highly accurate elemental analysis

of ferrous & non-ferrous metals

PDA-8000

How It Works

This analytical technique is commonly known as “arc spark spectrometry”.

This is because it uses a short pulse of electrical spark to transfer energy

to the atoms in the metal samples, which in turn emits lights that are

characteristic of the material. This information is used to identify its

chemical composition. The intensity of the light is indicative of the

concentration of the material within a sample. With standard samples

available, a calibration curve can be developed to measure the PDA-7000

concentration accurately.

Optical emission spectrometers use diffracting grating to diffract the

wavelengths of light before they reach detectors. As there is an array of

detectors, an analysis of tens of elements can be performed within a

minute. Optical emission spectrometers typically are capable of low

detection limit. In Shimadzu’s optical emission spectrometers, various

unique features, such as the time-resolution analysis and pulse distribution

analysis (PDA) photometry, make them the most sensitive and precise

OES on the market. PDA-5500 S

Major Advantages Areas of Application

Unlike ICP analysis or AAS analysis • Steel Industry

which requires meticulous sample • Cast Iron Industry

pre-treatments, OES analysis requires • Aluminium Ingot and

minimum sample pre-treatment. Only Rolling Industry

need to polish the sample surface to • Machinery Manufacturing Industry

make sure it is free from contaminants • Automobile Industry

and is uniformly flat. The analysis is non • Ship-building Industry

destructive. • Testing Service Industry PDA-5000

12 Excellence in Science