Page 5 - Material Characterizations

P. 5

Energy EDX Energy Dispersive X-Ray Fluorescence Spectrometer EDX

Dispersive

X-Ray WINNER OF IBO 2014 GOLD AWARD

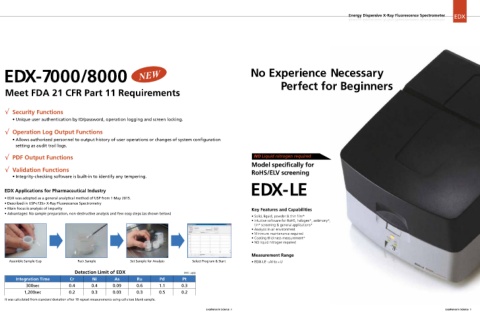

Fluorescence EDX-7000/8000 EDX-7000/8000 NEW No Experience Necessary

Spectrometer Perfect for Beginners

EDX One EDX over all others Meet FDA 21 CFR Part 11 Requirements

• Unique user authentication by ID/password, operation logging and screen locking.

NO Liquid nitrogen required √ Security Functions

Key Features and Capabilities √ Operation Log Output Functions

• High performance Silicon Drift Detector (SDD)

• High sensitivity, high resolution & high speed • Allows authorized personnel to output history of user operations or changes of system configuration

• Sleek design with small footprint setting as audit trail logs.

• Solid, liquid, powder & thin film

• Analysis in air, vacuum*, helium-purged* environment NO Liquid nitrogen required

• 12-sample turret* for solid & liquid samples √ PDF Output Functions

• New intuitive software for RoHS*, halogen*, antimony*, Model specifically for

tin* screening & general applications Validation Functions

• Minimum maintenance required √ RoHS/ELV screening

• Coating thickness measurement • Integrity-checking software is built-in to identify any tempering.

• NO liquid nitrogen required

Elemental Analysis EDX-LE

EDX Applications for Pharmaceutical Industry

Measurement Range

How It Works • EDX-7000 11Na to 92U • EDX was adopted as a general analytical method of USP from 1 May 2015.

An X-ray source irradiates a sample, which in turn emits fluorescent • EDX-8000 6C to 92U • Described in USP<735> X-Ray Fluorescence Spectrometry

x-rays. The fluorescent X-rays are characteristic of the material. This • Main focus is analysis of impurity Key Features and Capabilities

information is used to identify an unknown sample. • Advantages: No sample preparation, non-destructive analysis and few easy steps (as shown below)

• Solid, liquid, powder & thin film*

• Intuitive software for RoHS, halogen*, antimony*,

The intensity of the X-rays is indicative of the concentration of the

material within a sample. If a standard is available, a calibration curve tin* screening & general applications*

can be developed to measure the concentration accurately. • Analysis in air environment

• Minimum maintenance required

On the other hand, it is possible to estimate the concentration using NEW • Coating thickness measurement*

theoretical method in the absence of a standard. • NO liquid nitrogen required

Major Advantages Areas of Application Measurement Range

EDX-7000

Unlike ICP analysis or AAS analysis • Electrical & Electronic Materials Assemble Sample Cup Pack Sample Set Sample for Analysis Select Program & Start • EDX-LE 13AI to 92U

which requires meticulous sample • Chemical industry

pre-treatments, EDX analysis requires • Petroleum & Petrochemicals Detection Limit of EDX Unit : μg/g

minimum or no sample pre-treatment. • Building & Construction Materials

Quantitation is possible in the absence • Medical Supplies Integration Time Cr Ni As Ru Pd Pt

of a standard. This Is accomplished using • Agriculture and Food Products 300sec 0.4 0.4 0.09 0.6 1.1 0.3

theoretical approximation. • Iron, Steel & Non-Ferrous Metals

• Machinery & Automobiles 1,200sec 0.2 0.3 0.03 0.3 0.5 0.2

• Environment EDX-LE * Optional Item

It was calculated from standard deviation after 10 repeat measurements using cellulose blank sample.

6 Excellence in Science Excellence in Science 7 Excellence in Science 8 Excellence in Science 9