Page 11 - Pharmaceutical- Guide to Biopharmaceutical

P. 11

Cell Line Optimization

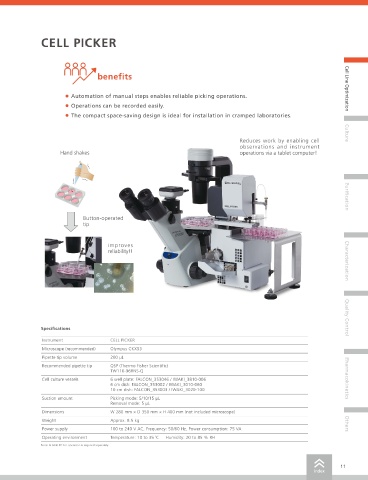

Cell Colony Picking CELL PICKER

Cell Colony Picking Method Used to Automate benefits

Picking Operations for Cell Genome Editing Cell Line Optimization

click here • Automation of manual steps enables reliable picking operations.

• Operations can be recorded easily.

Operating Principle and Features • The compact space-saving design is ideal for installation in cramped laboratories.

Table 1 Adherent Cell Cultivation Parameters

CELL PICKER has a technology to aspirate and discharge liquids. Cells: HCT116 cell line (human colon cancer cells)

After visually deciding the target cell colony, a button is pressed to McCoy’s 5A medium

automatically attach a pipette tip to the end of the nozzle and reliably Culture medium: with 10 % FBS, 2 mM glutamine added Culture

move the tip close to the target cell colony. When the tip scrapes Coating: Gelatin solution Reduces work by enabling cell

off the cell colony, the measuring pump simultaneously activates to Cultivation parameters: Let stand at 37 °C and 5 % CO2 observations and instrument

aspirate and then discharge the cell colony and a small amount of the Hand shakes operations via a tablet computer!

medium. Using a tablet computer for observations and operations can Genome-edited cells are

reduce the amount of work involved in operations. seeded to form colonies.

Procedure and Cultivation Parameters

6

A 6-well plate was seeded with 1×10 to 1×10 cells/well of human

4

colon cancer cells (HCT116 adherent cell line). After cultivating the cells Purification

for six days, the CELL PICKER was used to pick cells and seed a 96-well

plate. Then the same cultivation parameters were used to cultivate the

seeded cells for six days, after which the cell adhesion and proliferation

were checked. The operation process flow is illustrated in Fig. 1. Button-operated

tip

Results Cell colonies are picked with

CELL PICKER.

Cell colonies before and after picking are shown in Fig. 2. The picked improves

cells after cell proliferation are shown in Fig. 3. reliability!!

100 % of the seeded wells produced adherent cell cultures. Clones are established.

This example confirmed that cells can be picked and seeded without Characterization

causing cell damage. Fig. 1 Workflow image

Application Examples Before picking After picking

• Picking for establishing iPS cells

This confirmed that iPS cell colonies can be cultivated continuously

while maintaining their undifferentiated state.

• Collecting floating cell clusters (Spheroids)

The system can also be used for the purpose of collecting spheroids Fig. 2 Cell colonies before and after picking Quality Control

created by 3D cell culturing.

It can pick a single spheroid from among multiple spheroids in an Day1 Day4 Day5 Specifications

HEK293 cell line (400 to 500 μm) (Fig. 4).

Instrument CELL PICKER

Microscope (recommended) Olympus CKX53

Pipette tip volume 200 µL

Recommended pipette tip QSP (Thermo Fisher Scientific)

Note: These colonies are different than shown in “Cell colonies before and after picking.” TW110-96RNS-Q

Scale bar: 200 µm

Fig. 3 Cell proliferation after picking Cell culture vessels 6 well plate: FALCON_353046 / IWAKI_3810-006 Pharmacokinetics

6 cm dish: FALCON_353002 / IWAKI_3010-060

Before picking After picking 10 cm dish: FALCON_353003 / IWAKI_3020-100

Suction amount Picking mode: 5/10/15 µL

Removal mode: 5 µL

Dimensions W 280 mm × D 350 mm × H 400 mm (not included microscope)

Weight Approx. 8.5 kg Others

Power supply 100 to 240 V AC, Frequency: 50/60 Hz, Power consumption: 75 VA

The white dashed circles in the images are not shown in the software.

Note: The indicated operations require special operating software. Operating environment Temperature: 10 to 35 ˚C Humidity: 20 to 85 % RH

Fig. 4 Before and after picking spheroids Note: A table PC for operation is required separately.

10 11

index index