Page 10 - Shimadzu PDA-7000

P. 10

Principle of Optical Emission Spectrometry Applications of Optical Emission Spectrometry

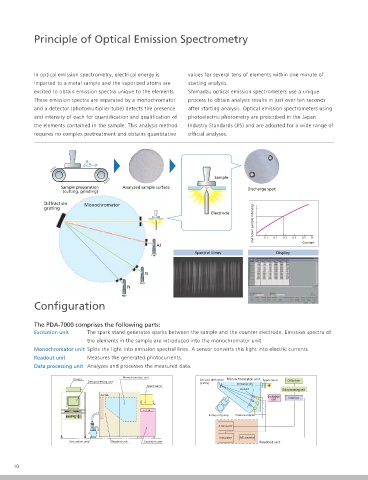

In optical emission spectrometry, electrical energy is values for several tens of elements within one minute of The Optical Emission Spectrometer covers a wide analysis components.

imparted to a metal sample and the vaporized atoms are starting analysis. range from trace levels to high concentrations of metals – It is used for process-control analysis and for raw materials

excited to obtain emission spectra unique to the elements. Shimadzu optical emission spectrometers use a unique including steel, aluminum, magnesium, copper, zinc, lead, delivery and product dispatch inspections in the metals

These emission spectra are separated by a monochromator process to obtain analysis results in just over ten seconds tin, titanium, nickel, and cobalt – in ingots or alloy refining and processing industries.

and a detector (photomultiplier tube) detects the presence after starting analysis. Optical emission spectrometers using

and intensity of each for quantification and qualification of photoelectric photometry are prescribed in the Japan Ferrous Applications

the elements contained in the sample. This analysis method Industry Standards (JIS) and are adopted for a wide range of

requires no complex pretreatment and obtains quantitative official analyses. Steel

- Quality control by rapid in-furnace analysis

at each stage of manufacture

- Analysis for product standards evaluation

- Materials deliver inspections

Cast Iron

Sample

- Quality control by rapid in-furnace analysis

Sample preparation Analyzed sample surface Discharge spot at each stage of manufacture

(cutting, grinding)

- Analysis for product standards evaluation

Diffraction Monochromator - Materials deliver inspections

Unknown sample intensity Non-ferrous Applications

grating

Electrode

Content

Al 0.1 0.2 0.3 0.4 0.5 % Aluminum Ingot and Rolling Industries

Spectral Lines Display Al - Quality control by rapid in-furnace analysis

PMT

at each stage of manufacture

- Analysis for product standards evaluation

Si - Materials deliver inspections

PMT

N Other Metals

- Quality control by rapid in-furnace analysis

PMT

at each stage of manufacture

Configuration - Analysis for product standards evaluation

other - Materials deliver inspections

The PDA-7000 comprises the following parts:

Excitation unit The spark stand generates sparks between the sample and the counter electrode. Emission spectra of

the elements in the sample are introduced into the monochromator unit. Machinery, Automobile, and

Monochromator unit Splits the light into emission spectral lines. A sensor converts this light into electric currents. Ship-building Applications

Readout unit Measures the generated photocurrents.

Data processing unit Analyzes and processes the measured data.

- Analysis for product standards evaluation

Monochromator unit - Materials deliver inspections

Printer Concave diffraction Monochromator unit Spark stand

Data processing unit grating Entrance slit CRT/printer

Spark stand

Exit slit Data processing unit

PDA-7000 Excitation

unit Interface

Rotary oil pump Photomultiplier

Attenuator

Integrator A/D converter

Evacuation unit Readout unit Excitation unit Readout unit

PDA-7000 Series

10 Optical Emission Spectrometer 11