Page 15 - Shimadzu PDA-7000

P. 15

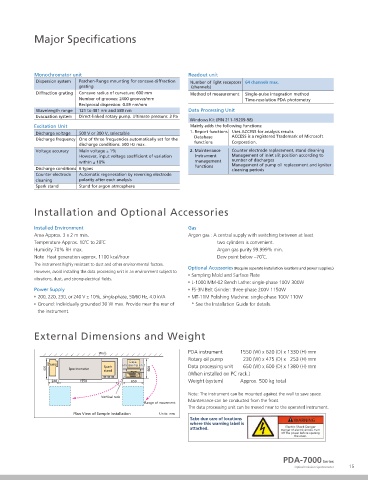

Options Major Specifications

Options for Sample Preparation Monochromator unit Readout unit

Dispersion system Paschen-Runge mounting for concave diffraction Number of light receptors 64 channels max.

grating (channels)

1. Sampling Mold and Surface Plate 2. FS-3N Belt Grinder 3. L-1000 MM-02 Bench Lathe Diffraction grating Concave radius of curvature: 600 mm Method of measurement Single-pulse integration method

Mold – P/N 210-00005 50Hz ɿ P/N 085-50206-15 P/N 085-50102-02 Number of grooves: 2400 grooves/mm Time-resolution PDA photometry

60Hz ɿ P/N 085-50206-16 Reciprocal dispersion: 0.69 nm/mm

Wavelength range 121 to 481 nm and 589 nm Data Processing Unit

Evacuation system Direct-linked rotary pump. Ultimate pressure: 2 Pa

Windows Kit (P/N 211-19209-98)

Excitation Unit Mainly adds the following functions:

Discharge voltage 500 V or 300 V, selectable 1. Report functions Uses ACCESS for analysis results

Discharge frequency One of three frequencies automatically set for the Database ACCESS is a registered Trademark of Microsoft

discharge conditions. 500 Hz max. functions Corporation.

Surface plate – P/N 210-00006 three-phase 200V 1150W single-phase 100V 300W Voltage accuracy Main voltage ± 1% 2. Maintenance Counter electrode replacement, stand cleaning

W300 x D300 x H100mm W420 x D680 x H830mm, 97kg W770 x D420 x H360mm, 75kg However, input voltage coefficient of variation Instrument Management of inlet slit position according to

within ± 10% management number of discharges

Items 1) and 2) below must be ordered functions Management of pump oil replacement and igniter

4. MT-11M Polishing Machine with the bench lathe. Discharge conditions 6 types cleaning periods

Consumables (for 6 mm dia. tungsten electrodes) 1) O.D. holder (Tip holder) P/N 085-50102-12 Counter electrode Automatic regeneration by reversing electrode

P/N 085-50802-01 TCGCR/L1010F-08 cleaning polarity after each analysis

2) Tip (for non-ferrous samples) P/N 085-50102-13 Spark stand Stand for argon atmosphere

1. Tungsten electrode P/N 211-74362 TCGT080202FR/L-U KW10

2. Brush P/N 211-74965 3) Bench lathe stand E-17 P/N 085-50102-11

3. Pump oil, 1 liter P/N 017-30159-03 Size: W1200 x D600 x H740mm

Installation and Optional Accessories

Tungsten electrode

single-phase 100V 110W

W120 x D210 x H150mm,3kg Installed Environment Gas

Grinding wheel P/N 085-50802-51 Area Approx. 3 x 2 m min. Argon gas : A central supply with switching between at least

Temperature Approx. 10˚C to 28˚C two cylinders is convenient.

Humidity 70% RH max. Argon gas purity 99.999% min.

Standard Samples for Analysis Note Heat generation approx. 1100 kcal/hour Dew point below –70˚C.

Contact your Shimadzu representative for information on the selection and preparation of standard samples The instrument highly resistant to dust and other environmental factors.

for each analysis purpose. Also consult Shimadzu if chemical analysis is required. However, avoid installing the data processing unit in an environment subject to Optional Accessories (Require separate installation locations and power supplies.)

˙Shapes of Cast Aluminum Standard Sampling Mold and Surface Plate

Samples vibrations, dust, and strong electrical fields.

L-1000 MM-02 Bench Lathe: single-phase 100V 300W

Power Supply FS-3N Belt Grinder: three-phase 200V 1150W

˙ Cast Aluminum Standard Samples

200, 220, 230, or 240 V ± 10%, single-phase, 50/60 Hz, 4.0 kVA MT-11M Polishing Machine: single-phase 100V 110W

Cast aluminum standard samples for standardization (disk type), set of 5 Ground: Individually grounded 30 W max. Provide near the rear of * See the Installation Guide for details.

(P/N 080-94801-21) the instrument.

Standard accessory with PDA-7000, Al base fixed channel. Disk type Pechiney type

˙ Cast Iron Standard Samples

˙Shapes of Cast Iron Standard External Dimensions and Weight

These standard samples are created using Shimadzu's many years of Samples

research and experience. They are white pig iron samples of alloy cast iron and normal cast iron, offering highly

reliable carbon analysis and an adequate concentration range of component elements for optical emission PDA instrument 1550 (W) x 620 (D) x 1330 (H) mm

spectrometry. Wall

ɾCast iron standard sample for standardization (disk type), set of 3 (P/N 211-72591-92) Data Rotary oil pump 230 (W) x 475 (D) x 253 (H) mm

Data

processing unit

One set of 3 supplied as standard accessory with PDA-7000, Fe base fixed channel. 620 Pump Spark processing unit Data processing unit 650 (W) x 600 (D) x 1380 (H) mm

ɾNo. 21 Cast iron standard sample for calibration curves (mushroom type), set of 10 (P/N 210-00004-21) Spectrometer stand 600

(When installed on PC rack.)

Disk type Mushroom type

240 1550 650 Weight (system) Approx. 500 kg total

˙ Low-alloy Steel Standard Samples Note: The instrument can be mounted against the wall to save space.

No. 5 Low-alloy Steel Standard No.14 Low-alloy Steel Standard Vertical rack

Samples for Calibration Curves Sample for Standardization Maintenance can be conducted from the front.

These standard samples contain many component elements in concentration ranges Range of movement

found in actual low-alloy steels. The concentrations are strictly controlled to ensure The data processing unit can be moved near to the operated instrument.

high reliability. Plan View of Sample Installation Units: mm

ɾNo. 14 Low-alloy steel standard sample for Take due care of locations WARNING

standardization (disk type), set of 3 (P/N 239-00100) where this warning label is Electric Shock Danger

attached.

Supplied as standard accessory with PDA-7000, Fe base fixed channel. Danger of electric shocks. Turn

off the power before opening

ɾNo. 5 Low-alloy steel standard sample for calibration curves (disk type), set of 10 the cover.

(P/N 210-00004-05) P/N 210-00004-05 P/N 239-00100

PDA-7000 Series

14 Optical Emission Spectrometer 15