Page 19 - Shimadzu MXF-2400

P. 19

Specifications Optional Accessories for Sample Preparation

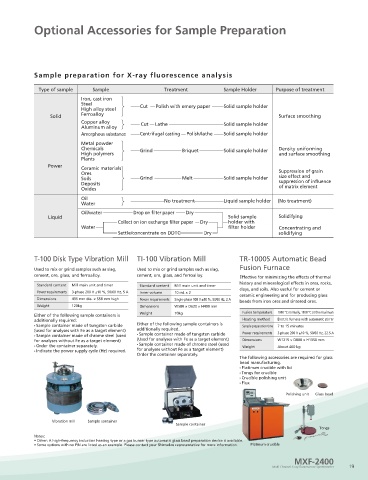

1. X-ray Fluorescence Spectrometer X-ray Protection Sample preparation for X-ray fluorescence analysis

Warning: Yellow lamp on the front panel and red lamp on the X-ray control panel.

Elements to be determined: 4Be ~ 92U Safety device: If the sample setter and the X-ray shutter are opened at the

Elements determined simultaneously: Up to 36 elements same time, the X-ray tube will be automatically turned off. Type of sample Sample Treatment Sample Holder Purpose of treatment

Mode of analysis: Simultaneous determination of many elements Also the moment the panel is opened the X-ray output is cutoff.

Atmosphere: Vacuum, air, helium (optional) Iron, cast iron

Steel Cut Polish with emery paper Solid sample holder

Spectrometer Unit X-ray Tube Cooling Unit (CWC-16, incorporated in the main body) High alloy steel

Ferroalloy

Fixed monochrometer: Converging method with curved crystal. Type: Circulation of distilled water (a 18-liter tank is attached.) Solid Surface smoothing

Vacuum type for all the elements. Method of heat exchange: Carried out in a dual tube between external Copper alloy Cut Lathe Solid sample holder

Crystal: SX, TAP, PET, Ge, NaCl, LiF cooling water and the distilled water. Aluminum alloy

Detector: Gas sealed detector for 11Na ~ 92U Heat exchange capacity: 4 kW (3.440 kcal / hour) Amorphous substance Centrifugal casting Polish/lathe Solid sample holder

Ne, Ar, Kr exatron Water purity maintenance: By ion exchange

Ne, Ar, Kr multitron Alarm: Temperature, flow rate, and electric conductivity Metal powder

FPC for 5B, 6C, 8O, 9F External cooling water: Necessary (Not necessary if using HYCOOL 30) Chemicals Grind Briquet Solid sample holder Density uniforming

Scanning monochrometer (optional): Parallel beam method with flat crystal. High polymers and surface smoothing

Used for heavy elements Plants

Crystal: LiF Power

Detector: Scintillation counter (SC) 2. Data Processing Unit Ceramic materials Suppression of grain

Elements to be determined: 22Ti ~ 92U (with crystal for heavy element Ores size effect and

determination) Hardware (IBM PC / AT compatible) Soils Grind Melt Solid sample holder suppression of influence

Present mechanism: Up to 30 elements may be preset OS: Windows XP Deposits of matrix element

Main Memory: 256MB or more Oxides

Measuring Electronics Keyboard: Full keyboard Oil

Floppy disk: 3.5"double-sided, double density (1.44 MB / disk). Single drive. No treatment Liquid sample holder (No treatment)

Type: Pulse counting system for all the elements controlled with a microprocessor Hard disk: 10GB or more Water

9

Counting capacity: 4 × 10 counts/element Printer: Laser printer

Counting method: integration for the preset time Oil/water Drop on filter paper Dry

Integration time: Adjustable for each group, from 1 to 999 seconds Liquid Solid sample Solidifying

High voltage supply for detector: 1,550 to 2,150 V Software Collect on ion exchange filter paper Dry holder with

Program for quantitative analysis Water Settle/concentrate on DDTC Dry filter holder Concentrating and

Maximum number of elements to be processed: Arbitrary number of elements solidifying

X-ray Generator

X-ray tube: End window type with Rh target. Maximum number of elements to be simultaneously determined: 36 per sample

Number of analysis groups: Arbitrary number of groups

X-ray window: Beryllium window (Thin Window) Repeated analysis: Arbitrary number of times

Maximum output: 4 kW Priority interrupt analysis: Possible, automatic return to sequential analysis

X-ray power controller Printout: Printout order can be specified for each group. Compound names and T-100 Disk Type Vibration Mill TI-100 Vibration Mill TR-1000S Automatic Bead

Rectification: Full wave rectification and smoothing with a capacitor element names may be printed out. Pass and fail marks may be printed

Control method: Secondary side detection, primary side control, control with the out. Used to mix or grind samples such as slag, Used to mix or grind samples such as slag, Fusion Furnace

CPU Number of calibration curves: Per each group, per each element cement, ore, glass, and ferroalloy. cement, ore, glass, and ferroalloy.

Maximum rating: 50 kV, 100 mA, 4 kW Type of calibration curve: Second-order polynomial Effective for minimizing the effects of thermal

Stability: ±0.01% (for 10% source fluctuation), both the current and voltage Correction for dead time Standard content Mill main unit and timer Standard content Mill main unit and timer history and mineralogical effects in ores, rocks,

Tube voltage setting: 5 kV steps from 20 to 50 kV Correction for absorption and enhancement: Per each group, per each element Power requirements 3-phase 200 V ±10 %, 50/60 Hz, 5 A clays, and soils. Also useful for cement or

Tube current setting: 50 kA steps form 5 to 100 mA Maximum number of elements to be corrected for absorption and enhancement: Inner volume 10 mL × 2 ceramic engineering and for producing glass

Safety circuit: Against overvoltage, overcurrent, overload, and abnormal cooling Arbitrary number of elements per equation Dimensions 435 mm dia. × 558 mm high Power requirements Single-phase 100 V ±10 %, 50/60 Hz, 2 A beads from iron ores and sintered ores.

water supply Weight 120kg

Correction for drift: 2-point method or 1-point method Dimensions W580 × D620 × H400 mm

Correction for overlapping: 2-point method or 1-point method Weight 70kg Fusion temperature 1000 °C normally, 1100 °C at the maximum

Sample Feeding Mechanism Internal standard method: Available for each group or each element Either of the following sample containers is Heating method Electric furnace with automatic stirrer

additionally required:

Type: Accurate sample positioning with a swing arm type sample feeder Chemical correction: 2-point method or 1-point method • Sample container made of tungsten carbide Either of the following sample containers is Sample preparation time 7 to 15 minutes

Turntable: Accepts 8 samples together Number of calculation formula: Arbitrary channels for concentration calculation (used for analyses with Fe as a target element) additionally required.

Spinner: 60 rpm (50/60 Hz) Program for scanner: Arbitrary number of elements • Sample container made of chrome steel (used • Sample container made of tungsten carbide Power requirements 3-phase 200 V ±10 %, 50/60 Hz, 22.5 A

Sample holder: 64 mmf, 43 mm high Program for qualitative analysis for analyses without Fe as a target element) (Used for analyses with Fe as a target element) Dimensions W1215 × D800 × H1350 mm

Max. sample size: 51 mmf, 38 mm high Scanner: For heavy element determination • Order the container separately. • Sample container made of chrome steel (used Weight About 460 kg

Method: Step scanning • Indicate the power supply cycle (Hz) required. for analyses without Fe as a target element)

Method of processing: Automatic peak search and automatic peak element Order the container separately.

Evacuation System determination The following accessories are required for glass

Oil rotary pump: Data output: 0n display and printer bead manufacturing.

Evacuation rate: About 130 L / 160 L /min. (50/60 Hz) Factor calculation • Platinum crucible with lid

Oil mist filter provided Calibration factor: By the method of least squares, up to second-order polynomial • Tongs for crucible

Vacuum gauge: Pirani gauge, constant temperature type Factor for correcting absorption and enhancement: By the method of multiple • Crucible polishing unit

Vacuum stabilizer: Controlled with a microcomputer. The degree of vacuum can regression (concentration correction and sensitivity correction) • Flux

be stabilized at an arbitrary point. Maintenance program

Pulse height distribution: Graphic display Polishing unit Glass bead

Monochromator alignment aid: Graphic display

Gas Supply System for Flow Proportional Counter Counter unit: Graphic display

Use: Used of determination of B, C, N, O, and F Alarm: Display of alarm number, cause, and measure.

Gas: PR gas (Ar 90% and CH4 10%) Manual instrument diagnosis: Parts by part check is possible.

Gas flow consumption: 10 to 15 mL /min. External transmission program: Analysis data may be transmitted externally, in Vibration mill Sample container

Gas density stabilizer: Controlled by a microcomputer qualitative analysis. Sample container

Flow control: Needle valve and flow meter External transmission (analysis results, errors, etc.) Tongs

Gas cylinder: A 6 Nm cylinder (If light elements (4Be~9F) are attached) LAN and RS-232C (optional) Notes:

3

Automatic notification via e-mail possible • Other: A high-frequency induction heating type or a gas burner type automatic glass bead preparation device is available.

• Some options with no P/N are listed as an example. Please contact your Shimadzu representative for more information. Platinum crucible

MXF-2400

18 Multi-Channel X-ray Fluorescence Spectrometer 19