Page 12 - Shimadzu EZ Test

P. 12

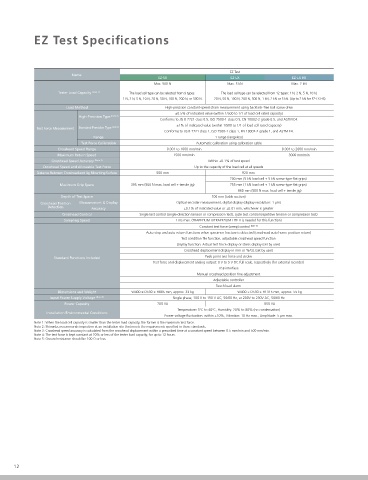

EZ Test Speci cations Options

EZ Test Tester Options

Name

EZ-SX EZ-LX EZ-LX HS

Max. 500 N Max. 5 kN Max. 2 kN Jog Controller Safety Cover

346-55922-01 EZ-SX: 346-57107-01

Tester Load Capacity (note 1) The load cell type can be selected from 9 types: The load cell type can be selected from 12 types: 1 N, 2 N, 5 N, 10 N, The jog dial is provided to allow nger-tip EZ-LX: 346-57107-02

1 N, 2 N, 5 N, 10 N, 20 N, 50 N, 100 N, 200 N, or 500 N. 20 N, 50 N, 100 N, 200 N, 500 N, 1 kN, 2 kN or 5 kN. (Up to 2 kN for EZ-LX HS) operation of the crosshead position. This is used to prevent injury when sample

fragments are scattered due to fracture.

Load Method High-precision constant-speed strain measurement using backlash-free ball screw drive

±0.5% of indicated value (within 1/500 to 1/1 of load cell rated capacity)

High-Precision Type (note 2)

Conforms to JIS B 7721 class 0.5, ISO 7500-1 class 0.5, EN 10002-2 grade 0.5, and ASTM E4.

±1% of indicated value (within 1/500 to 1/1 of load cell rated capacity) Control I/O Expansion Box Analog Recorder

Test Force Measurement Standard-Precision Type (note 2) 346-55920-01

Conforms to JIS B 7721 class 1, ISO 7500-1 class 1, EN 10002-2 grade 1, and ASTM E4. Increases the number of control I/O ports to X-T type: 346-59210-01

Range 1 range (rangeless) four. Multiple optional accessories can be Plots test force - time curves.

Test Force Calibration Automatic calibration using calibration cable simultaneously connected to the control I/O X-YT type: 346-51736-01

ports. Plots test force – time curves and test force –

Crosshead Speed Range 0.001 to 1000 mm/min 0.001 to 2000 mm/min

stroke curves.

Maximum Return Speed 1500 mm/min 3000 mm/min

Crosshead Speed Accuracy (Note 3) Within ±0.1% of test speed

Crosshead Speed and Allowable Test Force Up to the capacity of the load cell at all speeds Sensor I/O Expansion Box Power Cable

346-55920-02 For EU (VDE standard)

Distance Between Crosshead and Jig Mounting Surface 500 mm 920 mm Increases the number of tester sensor I/O 348-34063-03

700 mm (5 kN load cell + 5 kN screw type at grips) ports to two. Multiple optional accessories

Maximum Grip Space 395 mm (500 N max. load cell + tensile jig) 755 mm (1 kN load cell + 1 kN screw type at grips) can be simultaneously connected to the For China (GB standard)

348-34063-02

sensor I/O ports. BNC cables can be

860 mm (500 N max. load cell + tensile jig) connected to the analog I/O ports. For Japan and North America (UL, CSA, PSE standards)

Depth of Test Space 100 mm (table section) 348-34063-01 is provided as standard.

Crosshead Position Measurement & Display Optical encoder measurement, digital display (display resolution: 1 µm) A variety of other options are also available. For details, refer to the separate catalog "Optional Accessories for Autograph".

Detection Accuracy ±0.1% of indicated value or ±0.01 mm, whichever is greater

Crosshead Control Single test control (single-direction tension or compression test), cycle test control (repetitive tension or compression test)

Sampling Speed 1 ms max. (TRAPEZIUM X/TRAPEZIUM LITE X is needed for this function)

Constant test force (creep) control (note 4) Additional Load Cell Kits

Auto-stop and auto-return functions when specimen fracture is detected (crosshead auto home-position return)

Test condition le function, adjustable crosshead speed function Select a load cell kit if load cells are to be added to the tester unit kit. The additional load cell kit comprises a cell set (load cell and

Display function: Actual test force display or stress display (set by user) calibration cable), cell bolt (if required), and upper joint jig (if required).

Crosshead displacement display in mm or %/GL (set by user)

Standard Functions Included Peak point test force and stroke LOAD CELL SET (Load cell, calibration cable and calibration)

Test force and displacement analog output: 0 V to 5 V DC full scale, respectively (for external recorder)

USB interface EZ-LX

Manual crosshead position ne adjustment CLASS EZ-TEST - EZ-LX HS

Adjustable controller - EZ-SX

Touch load alarm P/N 5 kN 2 kN 1 kN 500 N 200 N 100 N 50 N 20 N 10 N 5 N 2 N 1 N

Dimensions and Weight W400 × D530 × H885 mm, approx. 33 kg W400 × D530 × H1315 mm, approx. 55 kg 1 346-55939-XX 10 14 9 13 12 07 06 05 04 03 02 01

Input Power Supply Voltage (Note 5) Single phase, 100 V to 150 V AC, 50/60 Hz, or 200V to 230V AC, 50/60 Hz 0.5 346-55942-XX 10 14 9 13 12 07 06 05 04 03 02 01

Power Capacity 700 VA 850 VA

Temperature: 5°C to 40°C, Humidity: 20% to 80% (no condensation)

Installation Environmental Conditions

Power voltage uctuation: within ±10%, Vibration: 10 Hz max., Amplitude: 5 m max.

Note 1: When the load cell capacity is smaller than the tester load capacity, the former is the maximum test force. Thermostatic Chamber Installation Space

Note 2: Shimadzu recommends inspection at an installation site that meets the requirements speci ed in these standards.

Note 3: Crosshead speed accuracy is calculated from the crosshead displacement within a prescribed time at a constant speed between 0.5 mm/min and 500 mm/min. Allows testing within an ambient

Note 4: The test force is kept constant at 70% or less of the tester load capacity, for up to 12 hours. (unit: mm)

Note 5: Ground resistance should be 100 or less. temperature range of -70°C to 250°C. Wall surface

Thermostatic chambers are available only

for EZ-L type testers. Power supply input

The chambers are special-order items. For Anti-topple attachment (710 mm above oor) 600 Worktable

(When a worktable of

(included in the tester

details, please make a separate inquiry. unit kit) height 650 mm is used) (optional)

Other Options 250

Description P/N Remarks 125

Worktable 340-48580-02 Worktable for EZ Test 38

600 400 485

346-55037-12 Secures the tester unit to the worktable.

Anti-topple attachment 420 475

for EZ-SX/EZ-LX 346-55037-11 Secures the tester unit to the worktable,

or the worktable to the oor.

Note: A similar installation space is required for both EZ-SX and EZ-LX.

EZ Test

12 Table-Top Universal Testing Instruments 13