Page 15 - Shimadzu EZ Test

P. 15

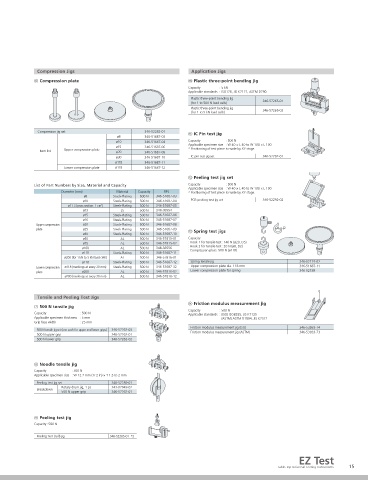

Jig Part Number List

*1 : 52 An upper adapter jig is necessary *2 : 53 A lower adapter jig is necessary *3 : 51 A jig platform is necessary

Probes Compression Jigs Application Jigs

Indentation elasticity test jig / Cylindrical press jig Piercing needle jig / Indentation test jig Compression plate Plastic three-point bending jig

Capacity : 5 kN

Applicable standards : ISO178, JIS K7171, ASTM D790

Plastic three-point bending jig

(for 1 to 500 N load cells) 346-57265-01

Plastic three-point bending jig 346-57265-02

(for 1 to 5 kN load cells)

40 mm

40 mm 40 mm 40 mm Angle 60°

Indentation elasticity test jig / cylindrical press jig Lower compression plate Piercing needle jig / indentation test jig Lower compression plate

Compression jig set 346-52282-01 IC Pin test jig

Indentation elasticity test jig set 346-52284-01 Indentation elasticity test jig set 346-52283-01 ø8 346-51687-03

Indentation elasticity test jig dia. 3 mm 346-51687-01 Indentation elasticity test jig dia. 3 mm 346-51813-01 ø10 346-51687-04 Capacity : 500 N

Item list Indentation elasticity test jig dia. 5 mm 346-51687-02 Item list Indentation elasticity test jig dia. 5 mm 346-51813-02 Upper compression plate ø15 346-51687-06 Applicable specimen size : W 40 × L 40 to W 100 × L 100

* Positioning of test piece is made by XY stage.

Lower compression plate dia. 118 mm 346-51687-12 Lower compression plate dia. 118 mm 346-51687-12 Item list ø20 346-51687-08

ø30 346-51687-10 IC pin test jig set 346-52292-01

ø118 346-51687-11

List of Part Numbers by Size, Material and Capacity List of Part Numbers by Size, Material and Capacity Lower compression plate ø118 346-51687-12

Diameter (mm) Material Capacity P/N Diameter (mm) Material Capacity P/N

ø1 SS 5 N 346-38590-02 ø1 (60° taper) SS 5 N 346-57829-01 *1 Peeling test jig set

ø2 SS 20 N 348-38504-02 ø2 (60° taper) SS 20 N 348-38503-02 *1 Capacity : 500 N

SS 50 N 348-38504-03 SS 50 N 348-38503-03 *1 List of Part Numbers by Size, Material and Capacity

ø3 ø3 (60° taper) Applicable specimen size : W 40 × L 40 to W 100 × L 100

Steel+Plating 50 N 346-51687-01 SS 50 N 348-38502-01 Diameter (mm) Material Capacity P/N * Positioning of test piece is made by XY stage.

ø4 SS 200 N 348-38504-04 SS 200 N 348-38503-04 *1 ø8 Steel+Plating 500 N 346-51687-03

ø5 SS 500 N 348-38505 ø4 (60° taper) SS 200 N 348-38502-02 ø10 Steel+Plating 500 N 346-51687-04 PCB peeling test jig set 346-52292-02

Steel+Plating 500 N 346-51687-02 SS 500 N 348-38503-05 *1 ø11.3 (cross section: 1 cm 2 ) Steel+Plating 500 N 346-51687-05

ø6 SS 500 N 348-38506-01 ø5 (60° taper) SS 500 N 348-38502-03 ø13 SS 500 N 348-38554

ø7 SS 500 N 348-38506-02 ø15 Steel+Plating 500 N 346-51687-06

ø8 SS 500 N 348-38506-03 ø16 Steel+Plating 500 N 346-51687-07

ø9 SS 500 N 348-38506-04 Spherical press jig / Viscosity test jig Upper compression ø20 Steel+Plating 500 N 346-51687-08

SS 500 N 348-38506-05 plate ø25 Steel+Plating 500 N 346-51687-09 ø D

ø10 Spring test jigs

acrylic 100 N 346-57801-04 ø30 Steel+Plating 500 N 346-51687-10

SS 100 N 346-57801-03 ø50 AL 500 N 346-57815-01 Capacity

ø11.3 (cross section: 1 cm 2 )

acrylic 100 N 346-57801-07 ø75 AL 500 N 346-57815-02 : Hook 1 for tensile test: 140 N (ø20, D5)

AL 100 N 346-57801-08 : Hook 2 for tensile test: 20 N (ø8, D2)

ø15 ø100 AL 500 N 348-38556

acrylic 100 N 346-57801-09 ø118 Steel+Plating 500 N 346-51687-11 : Compression plate: 500 N (ø118)

AL 100 N 346-57801-01 ø200 (for 1 kN to 5 kN load cells) AL 500 N 346-57816-01

acrylic 100 N 346-57801-05 List of Part Numbers by Size and Material Spring tensile jig 346-52174-02

ø20 ø118 Steel+Plating 500 N 346-51687-12

AL 500 N 346-57802-09 Diameter (mm) Material Capacity P/N ø118 (markings at every 20 mm) Steel+Plating 500 N 346-51687-32 Upper compression plate dia. 118 mm 346-51687-11

acrylic 500 N 346-57802-18 ø3 SS 100 N 348-38511-01 Lower compression ø200 AL 500 N 346-57816-02 Lower compression plate for spring 346-52189

AL 500 N 346-57802-01 plate

ø25 ø4 SS 100 N 348-38511-02 ø200 (markings at every 30 mm) AL 500 N 346-57816-12

acrylic 200 N 346-57802-11 ø5 SS 100 N 348-38511-03

AL 500 N 346-57802-20

ø30 ø6 SS 100 N 348-38511-04

acrylic 200 N 346-57802-21 ø7 SS 500 N 348-38511-05

AL 500 N 346-57802-02

ø35 ø8 SS 500 N 348-38511-06

acrylic 200 N 346-57802-12 ø9 SS 500 N 348-38511-07 Tensile and Peeling Test Jigs

346-57802-03

ø36 AL 500 N (AOAC, bread compression test) ø10 SS 500 N 348-38511-08 Friction modulus measurement jig

ø15 SS 500 N 348-38512-01 500 N tensile jig

AL 500 N 346-57802-04 Capacity : 500 N

ø40 ø20 SS 500 N 348-38512-02 Capacity : 500 N Applicable standards : (ISO) ISO8295, JIS K7125

acrylic 200 N 346-57802-13 Applicable specimen thickness : 5 mm

AL 500 N 346-57802-05 ø25 SS 500 N 348-38512-03 (ASTM) ASTM D1894, JIS K7312

ø45 ø3.2 (ø1/8”) SS 20 N 348-38511-09 Grip face width : 25 mm

acrylic 200 N 346-57802-14

AL 500 N 346-57802-06 ø6.4 (ø1/4”) SS 100 N 348-38511-10 500 N tensile jig set (one each for upper and lower grips) 346-57262-03 Friction modulus measurement jig (ISO) 346-53933-74

ø50 ø12.7 (ø1/2”) SS 500 N 348-38511-11 Friction modulus measurement jig (ASTM) 346-53933-73

acrylic 200 N 346-57802-15 500 N upper grip 346-57262-01

ø6.4 (ø1/4”) SS 500 N 348-38506-06 ø19.1 (ø3/4”) SS 500 N 348-38512-04 500 N lower grip 346-57262-02

AL 100 N 346-57801-02 acrylic 500 N 348-38555-01

ø12.7 (ø1/2”) 346-57801-06 SS 500 N 348-38512-05

acrylic 100 N ø25.4 (ø1”)

(JIS/ISO, gelatin test) acrylic 500 N 348-38555-02

AL 500 N 346-57802-07

ø25.4 (ø1”)

acrylic 200 N 346-57802-16

ø30 mm

ø30 mm

AL 500 N 346-57802-10 ø30 mm ø30 mm Noodle tensile jig

ø38.1 (ø3/2”)

acrylic 200 N 346-57802-19 Capacity : 500 N

AL 500 N 346-57802-08 Applicable specimen size : W 12.7 mm (1/ 2 in) × T 1.5 to 2 mm

ø50.8 mm (ø2”) Conical press jigs

acrylic 200 N 346-57802-17

SS 500 N 346-57803-01 Jig Diameter: ø30 mm Peeling test jig set 346-52289-01

ø1/2” (round tipped) Rotary drum jig, 1 pc 343-07949-02

acrylic 500 N 346-57803-11 Breakdown

SS 100 N 346-57803-02 500 N upper grip 346-57262-01

ø1” (round tipped) List of Part Numbers by Size and Material Angle

acrylic 100 N 346-57803-12

Angle Material Capacity P/N

90° acrylic 100 N 346-57806-01 *1

60° acrylic 100 N 346-57806-02 *1

Multi-piercing jig acrylic 100 N 346-57806-03 *1 Peeling test jig

45°

Capacity : 500 N SS 100 N 346-57806-04 *1 Capacity: 500 N

Each Prove : ø3 mm, Angle 15° (9 Proves) acrylic 100 N 346-57806-05 *1

40°

SS 100 N 346-57806-06 *1

Multi-piercing jig 346-57804 acrylic 100 N 346-57806-07 *1 Peeling test (cell) jig 346-52265-01 *2

30°

SS 100 N 346-57806-08 *1

EZ Test

14 Table-Top Universal Testing Instruments 15