Page 14 - Shimadzu CFT-EX Series

P. 14

global w430×h280

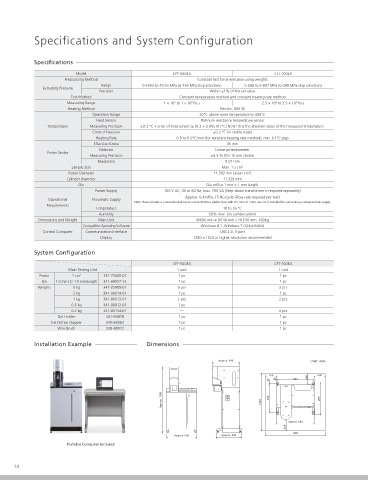

Specifications and System Configuration Options

Specifications Optional Additional Dies (Nozzles)

Model CFT-500EX CFT-100EX Die Orifice I.D. × Length (mm) Shape and Material P/N

Pressurizing Method Constant test force extrusion using weights 0.3 × 1.0 341-69057-02 Viscosity 10 6

(Pa·s)

Range 0.4903 to 49.03 MPa (0.493 MPa step selection) 0.098 to 9.807 MPa (0.098 MPa step selection) 0.5 × 0.5 341-69057-03

Extruding Pressure

Precision Within ±1% of the set value 0.5 × 1.0 341-69057-04 10 5

Flat

Test Method Constant temperature method and constant heating rate method 0.5 × 2.0 (high speed tool steel: 341-69057-06

Measuring Range 1 × 10 to 1 × 10 Pa·s 2.5 × 10 to 2.5 × 10 Pa·s 0.5 × 2.5 SKH material) 341-69057-07 10 4

0

5

1

6

Heating Method Electric, 500 W 1.0 × 1.0 (Included as standard) 341-69057-12

Operation Range 20°C above room temperature to 400°C 1.0 × 2.0 341-69057-13

Heat Sensor Platinum resistance temperature sensor 0.3 × 1.0 341-69057-22 10 3

Temperature Measuring Precision ±0.3 °C + error of heat sensor (± (0.3 + 0.005 |t|) °C) Note: |t| is the absolute value of the measured temperature. 0.5 × 0.5 341-69057-23

0.5 × 1.0 341-69057-24

Control Precision ±0.2 °C (in stable state) 10 2

Heating Rate 0.5 to 6.0°C/min (for constant heating rate method), min. 0.1°C step 0.5 × 1.5 341-69057-25

0.5 × 2.0 341-69057-26

Effective Stroke 15 mm

0.5 × 2.5 341-69057-27

Detector Linear potentiometer 10 1

Piston Stroke 0.5 × 5.0 341-69057-28

Measuring Precision ±0.5 % (for 15 mm stroke)

0.5 × 10.0 341-69057-29

Resolution 0.01 mm

1.0 × 5.0 Flat (stainless steel) 341-69057-34 10 0

Sample Size Max. 1.5 cm 3

1.0 × 10.0 341-69057-35

Piston Diameter 11.282 mm (area1 cm ) 2

2.0 × 2.0 341-69057-15

Cylinder Diameter 11.329 mm 10 -1

2.0 × 5.0 341-69057-17

Die Die orifice 1 mm × 1 mm length 2.0 × 10.0 341-69057-18 ø1 × 1

Power Supply 100 V AC, 50 or 60 Hz, max. 700 VA (Step-down transformer is required separately) ø1 × 10

3.0 × 3.0 341-69057-43

Approx. 0.4 MPa, 15 NL/cycle (Flow rate required per test) 3.0 × 6.0 341-69057-45 ø0.5 × 1

Operational Pneumatic Supply

Note: Please provide a connection that can be connected to a rubber hose with 9.5 mm I.D. (18.5 mm O.D.) included for connecting a compressed air supply. 341-69057-51

Requirements 2.095 × 8.0 Test Pressure

Temperature 10 to 35 °C No orifice 341-69057-52 0.098 0.98 1.96 9.8 49 (MPa)

Humidity 60% max. (no condensation) 0.5 × 10.0 Split type nozzle 341-68997-07

Dimensions and Weight Main Unit W690 mm × D640 mm × H1540 mm 160kg 1.0 × 10.0 (ultra-hard alloy) 341-68997 Reading the Graph

Compatible Operating Software Windows 8.1 ,Windows 7 (32bit/64bit) 0.5 × 10.0 Split type nozzle 341-68997-02

Control Computer Communication Interface USB 2.0, 1 port 1.0 × 10.0 (stainless steel) 341-68997-01 Given a die with a 1 mm diameter and 1 mm long orifice, for example, and a test pressure of 1.96 MPa

selected, then viscosities from 50 to 50,000 Pa·s can be measured.

Display 1280 × 1024 or higher resolution recommended Split type nozzle 341-69024 If the orifice length is 5 mm, then viscosity values would be 1/5 those above.

disassembly tool

System Configuration

Test Temperature and Pressure Range Extension Options

CFT-500EX CFT-100EX

Main Testing Unit 1 unit 1 unit Low Temperature Test Attachment High Temperature Heating Attachment Large Sample Heating Attachment

Piston 1 cm 2 347-25000-01 1 pc 1 pc (P/N 344-04024-11, 50 Hz; 344-04024-12, with a Piston (1 cm2) (P/N 347-25001-11)

60 Hz (with a transformer)) (P/N 344-81960-01) This heating attachment cylinder has a large

Die 1.0 mm I.D. 1.0 mm Length 341-69057-12 1 pc 1 pc

Weights 5 kg 347-25909-01 9 pcs 3 pcs Used for testing at low temperatures. Used for testing at high temperatures. cross-sectional area to decrease the test pressure to 1/4

2 kg 341-00014-01 1 pc 1 pc Temperature range: 0 to +90°C Temperature range: of the regular level.

1 kg 341-00013-01 2 pcs 2 pcs CHW-1 heating attachment included 20°C above room temperature to 500°C Model: CH-4P 2

0.5 kg 341-00012-01 1 pc Cylinder cross sectional area: 4 cm

Breakdown: Large heating attachment

0.2 kg 341-00134-01 4 pcs Piston 4 cm 2

Die Holder 341-69878 1 pc 1 pc

Die Orifice Stopper 341-69883 1 pc 1 pc Cylinder Cooling Options (Cool the cylinder with forced air to improve efficiency of constant heating rate tests)

Wire Brush 339-89172 1 pc 1 pc

Cylinder Cooling Fan (P/N 347-26025) Cylinder Cooling Piston (P/N 341-69997-02)

Installation Example Dimensions Cylinders must be cooled rapidly after constant heating Cylinders must be cooled rapidly after constant heating rate tests to

rate tests to prepare for the next test. The cooling fan prepare for the next test. This piston blows air on the cylinder to enable

attaches to the bottom of the heating attachment to rapid cooling.

Approx. 640 Unit: mm directly cool the heating attachment. Breakdown: Cylinder cooling piston and air hose

Note: Cannot be used with low-temperature test attachments. Note: Cannot be used with large sample heating attachments.

200 645

20 645 200

20 Sampling Options Utility Options

Preforming Die Unit and Hand Press (P/N 347-25008-01) Air Compressor (P/N 042-70040-01)

Approx. 1540 1040 200 200 Powdered samples can be difficult to insert in the cylinder. Molding Provide for sites without a compressed air supply.

1. Rated pressure

0.5 MPa

the samples in advance can make insertion easier.

Breakdown: · Preforming die unit (P/N 347-25009-01) 2. Discharge air volume 50 Hz: 20 L/min, 60 Hz: 24 L/min

Solid sample dimensions: Approx. I.D.11 × L13 mm 3. Tank capacity 30 L

· Hand press (P/N 347-25011)

Approx. 690

200 Press force: Max. approx. 1200 N

1085

Approx. 690 Approx. 590

Electronic Balance

Portable Computer Included Used to measure sample mass

CFT-EX Series

14 Capillary Rheometer Flowtester 15