Page 7 - Shimadzu Axis Supra+

P. 7

INTO THE BULK – ION SPUTTER SOURCES

+

The AXIS Supra is configured with the Minibeam 4, cluster ions. A unique capability of the Minibeam 6 to generate

high flux Ar monatomic ion source or the 20 keV Ar n + cluster ions has allowed the successful etching of

+

Minibeam 6 Ar n + gas cluster ion source (GCIS). inorganic materials such as titanium dioxide with significantly less

Both ion sources are fully integrated into the ESCApe ion induced chemical damage.

acquisition software for sputter cleaning or depth profile

experiments. Gas handling is fully automated for sputter Where cluster ion depth profiling is not required the Minibeam 4

profiling and includes pump/purge sequences to facilitate ion source is supplied. This ion source operates with continuously

changing to Helium gas for ion scattering spectroscopy (ISS). variable beam energies between 500 eV and 4 keV. The design

produces a high ion flux at low energy for improved interface

The Minibeam 6 is a multi-mode ion source which can operate resolution whilst retaining a high sputter rate.

+

+

in Ar n + cluster mode and Ar / He monatomic ion mode as

required. Recent development of gas cluster ion sources has • Choice of monatomic or multi-mode gas cluster ion sources.

opened up the possibility of depth profiling organic materials • Automated gas introduction and pressure regulation.

with retention of chemistry throughout the profile. Depth

+

profiles through complex multi-layer materials such as organic • Both sources capable of operating with He ions for optional

LEDs and flexible electronic devices are now possible with Ar n + ISS mode.

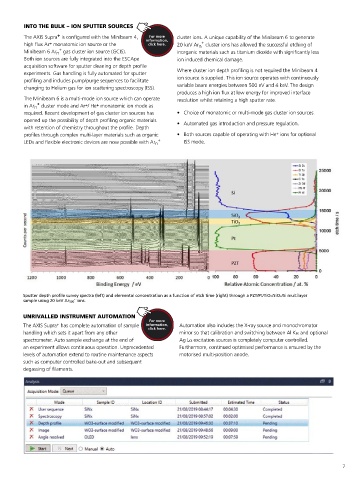

Sputter depth profile survey spectra (left) and elemental concentration as a function of etch time (right) through a PZT/Pt/TiO2/SiO2/Si multilayer

+

sample using 20 keV Ar 500 ions.

UNRIVALLED INSTRUMENT AUTOMATION

The AXIS Supra has complete automation of sample Automation also includes the X-ray source and monochromator

+

handling which sets it apart from any other mirror so that calibration and switching between Al Ka and optional

spectrometer. Auto sample exchange at the end of Ag La excitation sources is completely computer controlled.

an experiment allows continuous operation. Unprecedented Furthermore, continued optimised performance is ensured by the

levels of automation extend to routine maintenance aspects motorised multi-position anode.

such as computer controlled bake-out and subsequent

degassing of filaments.

7