Page 68 - Application Handbook - TOC

P. 68

Sum Parameter – Total Organic Carbon

TOC – Measurement principle

Catalytic combustion at 680°C

SCA-130-509

■TOC-Measurement principle Salt interference at the detection cell from the

The organic carbon compound is oxidized by salt melt products may impact the quality and

combustion to carbon dioxide. The carrier gas accuracy of the data. Maintenance time is

(transporting the CO 2) is cooled and also increased due to the extended cool

dehumidified and passed through a halogen down and reheating time required based on

scrubber into the cell of the NDIR (Non the higher combustion temperature.

Dispersive Infrared) detector where the CO 2

is detected. The NDIR outputs a detection ■ Shimadzu TOC method

signal which generates a peak. Shimadzu developed the catalytically

oxidation at 680°C and uses peak area for

integration. This temperature is lower as the

melting points of some salts:

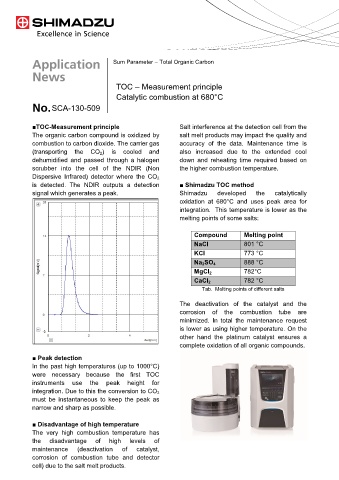

Compound Melting point

NaCl 801 °C

KCl 773 °C

Na 2SO 4 888 °C

MgCl 2 782°C

CaCl 2 782 °C

Tab. Melting points of different salts

The deactivation of the catalyst and the

corrosion of the combustion tube are

minimized. In total the maintenance request

is lower as using higher temperature. On the

other hand the platinum catalyst ensures a

complete oxidation of all organic compounds.

■ Peak detection

In the past high temperatures (up to 1000°C)

were necessary because the first TOC

instruments use the peak height for

integration. Due to this the conversion to CO 2

must be instantaneous to keep the peak as

narrow and sharp as possible.

■ Disadvantage of high temperature

The very high combustion temperature has

the disadvantage of high levels of

maintenance (deactivation of catalyst,

corrosion of combustion tube and detector

cell) due to the salt melt products.