Page 10 - Shimadzu SMV-301/301RT

P. 10

Speci cations and System Con guration Options

Speci cations 400 M Capability Graphic Printer (Printer cable provided) A

347-20931-11 (60 Hz) 347-20928-02 (For 120 V)

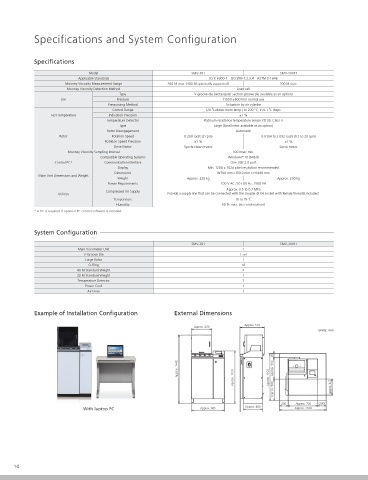

Model SMV-301 SMV-301RT

Applicable Standards JIS K 6300-1 ISO 289-1,2,3,4 ASTM D 1646 347-20931-12 (50 Hz) 347-20928-03 (For 230 V)

Mooney Viscosity Measurement Range 200 M max. (400 M optionally supported) 200 M max.

Mooney Viscosity Detection Method Load cell Mooney viscosities up to 400 M can be measured. Graphic printer for printing measurement data, test conditions,

Type V-groove die (rectangular section groove die available as an option)

Die Pressure 11500 ±500 N in normal use (Only compatible with SMV-301) statistical calculation results, graphs, and so on, on 110 mm

Pressurizing Method Actuation by air cylinder wide paper.

Control Range (20 ℃above room temp.) to 200 °C, in 0.1 ℃ steps

Test Temperature Indication Precision ±1 % Smaller and faster than an inkjet printer.

Temperature Detector Platinum resistance temperature sensor Pt100, Class A Small Rotor

Type Large (Small rotor available as an option) Cannot be used at the same time as the A4 size inkjet printer.

Rotor Disengagement Automatic 347-21104-11 Cannot be used in combination with the PC control software.

Rotor Rotation Speed 0.209 rad/s (2 rpm) 0.0104 to 2.092 rad/s (0.1 to 20 rpm) Articles of consumption: paper (10 rolls) 078-15031-21

Rotation Speed Precision ±1 % ±1 % Used for samples with high viscosity.

Drive Motor Synchronous motor Servo motor (Results in different values from those using the large rotor)

Mooney Viscosity Sampling Interval 100 msec min.

Compatible Operating Systems Windows 10 (64bit) Signal Tower B

®

Control PC* Communication Interface One USB 2.0 port

Display Min. 1280 × 1024 pixel resolution recommended 347-21260-10

Dimensions W700 mm x D510 mm x H1440 mm Rectangular-Section Groove Die

Main Unit Dimensions and Weight

Weight Approx. 220 kg Approx. 230 kg 347-20927-30 (Set of upper and lower dies) Allows the user to con rm the instrument power ON, testing,

Power Requirements 100 V AC, 50 / 60 Hz, 1500 VA

347-21109-10 (Upper die) and error status from a distance.

Approx. 0.5 to 0.7 MPa

Compressed Air Supply

Utilities Provide a supply line that can be connected with the coupler (R1/4 socket with female threads) included. 347-21107-30 (Lower die)

Temperature 10 to 35 ℃

Humidity 60 % max. (no condensation) Die with rectangular section grooves compliant with JIS K 6300 (1994) Anti-tip Bracket

* A PC is required if optional PC control software is included.

to JIS K 6300-1 (2001). 347-25913

B

Bracket used for preventing

System Con guration SMV-301 main unit from tipping to

PC Control Software (USB cable provided)

the concrete oor.

SMV-301 SMV-301RT 347-26080-02 (English)

Main Viscometer Unit 1 347-26080-03 (Chinese)

V-Groove Die 1 set

Large Rotor 1

O-Ring 10 Allows SMV-301/301RT units to be connected to a PC for con gur-

40 M Standard Weight 2 ing test conditions, displaying data, and analyzing data.

20 M Standard Weight 1

Temperature Detector 2

Power Cord 1 A

Air Hose 1

Automatic Calibration Unit (Automatic Weight Calibration Unit)

347-20926-01

Example of Installation Con guration External Dimensions Allows using simple operations via the touch panel to calibrate actual

weights and check weights quickly after calibration.

Approx. 510

Approx. 420

Units: mm

Casters

344-87850-12

(95)

Approx. 1440 Approx. 1100 Approx. 1100 Approx. 510 The casters make moving the instrument easy.

Approx. 500 Approx. 345 Anti-topple Attachment

200 Approx. 700 (200) 347-24975-03

Approx. 400

With laptop PC Approx. 685 Approx. 1100 Installed on both sides of the unit to prevent tipping.

With laptop PC

SMV-301/301RT

10 Mooney Viscometer 11