Page 20 - Shimadzu UH-X-FX Series

P. 20

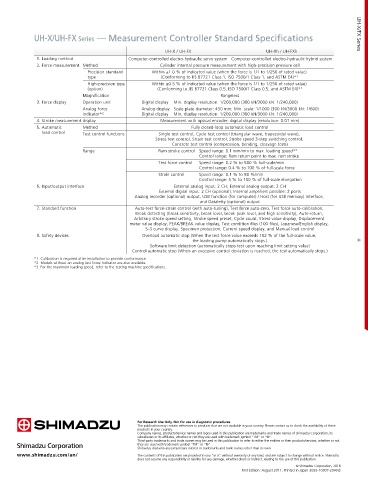

UH-X/UH-FX Series — Measurement Controller Standard Specifications UH-X/FX Series

UH-X / UH-FX UH-Xh / UH-FXh

1. Loading method Computer-controlled electro-hydraulic servo system Computer-controlled electro-hydraulic hybrid system

2. Force measurement Method Cylinder internal pressure measurement with high-precision pressure cell

Precision standard Within ±1.0 % of indicated value (when the force is 1/1 to 1/250 of rated value)

type (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and ASTM E4)* 1

High-precision type Within ±0.5 % of indicated value (when the force is 1/1 to 1/250 of rated value)

(option) (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, and ASTM E4)* 1

Magnification Rangeless

3. Force display Operation unit Digital display Min. display resolution: 1/200,000 (300 kN/3000 kN: 1/240,000)

Analog force Analog display Scale plate diameter: 450 mm; Min. scale: 1/1000 (300 kN/3000 kN: 1/600)

indicator* 2 Digital display Min. display resolution: 1/200,000 (300 kN/3000 kN: 1/240,000)

4. Stroke measurement display Measurement with optical encoder; digital display (resolution: 0.01 mm)

5. Automatic Method Fully closed-loop automatic load control

load control Test control functions Single test control, Cycle test control (triangular wave, trapezoidal wave),

Stress test control, Strain test control, Stroke speed 3-step switching control,

Concrete test control (compression, bending, cleavage tests)

Range Ram stroke control Speed range: 0.1 mm/min to max. loading speed* 3

Control range: Ram return point to max. ram stroke

Test force control Speed range: 0.2 % to 500 % full-scale/min

Control range: 0.4 % to 100 % of full-scale force

Strain control Speed range: 0.1 % to 80 %/min

Control range: 5 % to 100 % of full-scale elongation

6. Input/output interface External analog input: 2 CH; External analog output: 2 CH

External digital input: 2 CH (optional); Internal amplifiers possible: 2 ports

Analog recorder (optional) output, USB function (for computer) / Host (for USB memory) interface,

and Dataletty (optional) output

7. Standard function Auto-test force-strain control (with auto-tuning), Test force auto-zero, Test force auto-calibration,

Break detecting (break sensitivity, break level, break peak level, and high sensitivity), Auto-return,

Arbitrary stroke speed setting, Stroke speed preset, Cycle count, Stress value display, Displacement

meter value display, PEAK/BREAK value display, Test condition files (100 files), Japanese/English display,

S–S curve display, Specimen protection, Current speed display, and Manual load control

8. Safety devices Overload automatic stop (When the test force value exceeds 102 % of the full-scale value,

the loading pump automatically stops.)

Software limit detection (automatically stops test upon reaching limit setting value)

Control automatic stop (When an excessive control deviation is reached, the test automatically stops.)

*1 Calibration is required after installation to provide conformance.

*2 Models without an analog test force indicator are also available.

*3 For the maximum loading speed, refer to the testing machine specifications.

For Research Use Only. Not for use in diagnostic procedures.

This publication may contain references to products that are not available in your country. Please contact us to check the availability of these

products in your country.

Company names, products/service names and logos used in this publication are trademarks and trade names of Shimadzu Corporation, its

subsidiaries or its af liates, whether or not they are used with trademark symbol “TM” or “®”.

Third-party trademarks and trade names may be used in this publication to refer to either the entities or their products/services, whether or not

they are used with trademark symbol “TM” or “®”.

Shimadzu disclaims any proprietary interest in trademarks and trade names other than its own.

www.shimadzu.com/an/ The contents of this publication are provided to you “as is” without warranty of any kind, and are subject to change without notice. Shimadzu

does not assume any responsibility or liability for any damage, whether direct or indirect, relating to the use of this publication.

© Shimadzu Corporation, 2018

First Edition: August 2011, Printed in Japan 3655-10807-20ANS