Page 10 - Shimadzu DUH-211/

P. 10

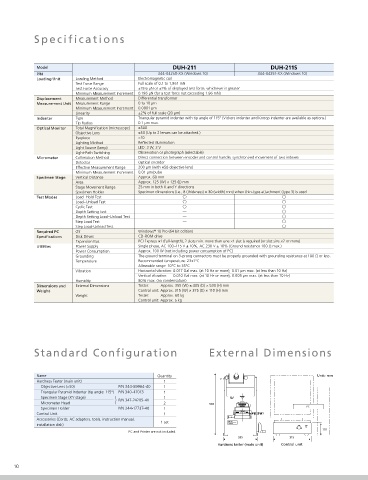

Specifications Optional Accessories

Model DUH-211 DUH-211S Length Measurement Kit BK7 (Glass Test Piece) P/N 339-89207-14 Slender Specimen Holder P/N 344-82943-40

(Color or Monochrome)

P/N 344-04250-XX (Windows 10) 344-04251-XX (Windows 10) Used to obtain the correction factors required for the This attachment is used to firmly hold thin specimens

Loading Unit Loading Method Electromagnetic coil Length measurement kit, color: P/N 347-24778-44 with an outer diameter of 0.15 mm to 1.6 mm, such as

Test Force Range Full scale of 0.1 to 1,961 mN Length measurement kit, monochrome: P/N 347-24778-43 indenter when measuring the elastic modulus. sewing machine needles, watch shafts, thin-shaped

Test Force Accuracy ±19.6 µN or ±1% of displayed test force, whichever is greater Microscope images of the specimen surface can be

Minimum Measurement Increment 0.196 µN (for a test force not exceeding 1.96 mN) displayed on the PC screen. Measure the size of medical equipment, wires, sintered wires, and nonferrous

Displacement Measurement Method Differential transformer indentations on the screen and save the images. Triangular Pyramid Indenter wires.

Measurement Unit Measurement Range 0 to 10 µm Maximum magnification factor is ×2400 (when using a with 100° Tip Angle

Minimum Measurement Increment 0.0001 µm 17″ monitor and an objective lens with a magnification P/N 340-47011

Linearity ±2% of full scale (20 µm) factor of 50). This accessory can be used with computers This indenter, with a tip

Indenter Type Triangular pyramid indenter with tip angle of 115° (Vickers indenter and Knoop indenter are available as options.) designated by Shimadzu. angle of 100°, has a Shape of indenter tip

Tip Radius 0.1 µm max. smaller tip radius and

Optical Monitor Total Magnification (microscope) ×500 makes smaller indentations γ

Objective Lens ×50 (Up to 2 lenses can be attached.) than an indenter with a tip α β

Eyepiece ×10 α = β = γ = 100°

Lighting Method Reflected illumination angle of 115°. Used for

Light Source (lamp) LED: 3 W, 3 V testing small-size

Light-Path Switching Observation or photograph (selectable) specimens.

Micrometer Collimation Method Direct connection between encoder and control handle; synchronized movement of two indexes

Detector Optical encoder

Effective Measurement Range 200 µm (with ×50 objective lens) Measurement Kit for Vickers Hardness Disk-Type Vacuum Suction Unit

Minimum Measurement Increment 0.01 µm/pulse P/N 347-24449-01 P/N 344-86201-42

Specimen Stage Vertical Distance Approx. 60 mm (Contents: Vickers Indenter 1 pc, Inspection Report 1 pc) Used for 5″, 6″, and 8″ wafers.

Area Approx. 125 (W) × 125 (L) mm The verification in accordance with standard (ISO (Air supply for suction must be separately prepared.)

Stage Movement Range 25 mm in both X and Y directions Objective Lens 6507-2) is done at the factory.

Specimen Holder Specimen dimensions (i.e., 8 (thickness) × 30 (width) mm) when thin-type attachment (type 3) is used Factory verified for compliance with Vickers hardness

Test Modes Load–Hold Test ×100 objective lens P/N 344-89977-40 test standards. Micrometer Head (Digital Display)

Load–Unload Test ×40 objective lens P/N 347-25400 Please order simultaneously with the DUH. P/N 347-25447-12 (2 unit)

Cyclic Test ×20 objective lens P/N 344-89924-40 Used to digitally display the amount of stage movement

Depth Setting Test ×10 objective lens P/N 344-89941-40 (up to a maximum of 25 mm) in the front/back or

Depth Setting Load–Unload Test ×40 objective lens with ultra-long operating distance Measurement Kit for Knoop Hardness

Step Load Test P/N 344-89300-41 P/N 347-24449-11 left/right directions in 1 µm increments. (Photo shows

Step Load-Unload Test 40× objective lens with ultra-long operating distance. this head attached to a stage.)

Required PC OS Windows 10 Pro (64 bit edition) Improves contrast in the field-of-view. (Contents: Knoop Indenter 1 pc, Inspection Report 1 pc)

®

Specifications Disk Drives CD-ROM drive The verification in accordance with standard (ISO

Expansion Bus PCI Express ×1 (full-length), 2 slots min. more than one ×1 slot is reguired (or slot size ×2 or more) 4545-2) is done at the factory.

Utilities Power Supply Single phase, AC 100–115 V ± 10%, AC 230 V ± 10% (Ground resistance 100 max.) Factory verified for compliance with Vickers hardness

Power Consumption Approx. 100 W (not including power consumption of PC) Windbreak test standards.

Grounding The ground terminal on 3-prong connectors must be properly grounded with grounding resistance at 100 or less. P/N 347-24400-01 Please order simultaneously with the DUH.

Temperature Recommended temperature: 23±1°C This case minimizes the influence of air disturbances,

Allowable range: 10°C to 35°C such as due to DUH tester exposure to air flow or sound.

Vibration Horizontal vibration: 0.017 Gal max. (at 10 Hz or more), 0.01 µm max. (at less than 10 Hz) W700 × D650 × H750 (mm) Desk-Type Vibration Absorbing Bench

Vertical vibration: 0.010 Gal max. (at 10 Hz or more), 0.005 µm max. (at less than 10 Hz) P/N 344-04193-06

Humidity 80% max. (no condensation) This bench with desk-type coil springs is recommended

Dimensions and External Dimensions Tester: Approx. 355 (W) × 405 (D) × 530 (H) mm Windbreak (Large type) if the DUH-211/211S tester is used in areas that are

Weight Control unit: Approx. 315 (W) × 375 (D) × 110 (H) mm P/N 347-24400-02 subject to strong vibrations.

Weight Tester: Approx. 60 kg In the case that Active Vibration-Absorbing Bench is used Rotation Stage

Control unit: Approx. 5 kg this is select. P/N 344-82857-01

W700 × D650 × H950 (mm) Active Vibration-Absorbing Bench This stage has a diameter of 125 mm and can rotate in

P/N 344-04211-11: AC 120 V the range ±5°.

P/N 344-04211-12: AC 230 V

Vickers Hardness Standard Block This bench is used together with a special mount and

P/N 340-06619-07 performs active vibration absorption over a wide range, Objective Micrometer

Used for measuring hardness with the 700HMV micro from 0.7 Hz to 100 Hz. P/N 046-60201-02

Vickers. Used as a rough guide for Vickers hardness Used to adjust the microscope's magnification factor.

measurement. Marked with scale graduations at 10 µm intervals.

Standard Configuration External Dimensions

Installation Precautions Consider the following points when deciding on the installation location of the tester.

Name Quantity Unit: mm

Hardness Tester (main unit) 1 1. To minimize vibration: 2. To minimize air drafts and sounds: 3. To ensure testing accuracy:

Objective Lens (×50) P/N 344-89964-40 1 1) Install the tester in a location where floor 1) Do not install the tester in locations that are Be especially careful when performing the following

Triangular Pyramid Indenter (tip angle: 115°) P/N 340-47013 1 vibration is minimal. Normally, place the tester on directly or indirectly subject to streams of air from types of tests:

• Tests involving test forces of 1 mN or less

air-conditioning equipment.

a vibration-absorbing bench.

Specimen Stage (XY stage) ) 1 2) Do not install the tester in a location where 2) Use a windbreak during testing. • Tests involving the measurement of changes for

Micrometer Head P/N 347-24205-41 2 530 people requently walk by. 3) Do not open or close nearby doors during testing. indentation depths of 0.05 µm or less

Specimen Holder P/N 344-17737-40 1 PC 3) Do not install the tester near equipment that 4) Do not install the tester near sound-generating In these cases, be sure to maintain the following

Control Unit 1 generates vibrations. equipment (e.g., telephones). conditions:

Accessories (Cords, AC adapters, tools, instruction manual, 4) If possible, install the tester on the first floor of a • Temperature: No fluctuations greater than ±1°C.

building.

• Vibration: Refer to specification table.

installation disk) 1 set 5) Install the tester as far away as possible from

PC and Printer are not included. 110 streets, roads and railway tracks.

355 315 6) Do not perform testing if vibration-generating

equipment (e.g., a crane) is being used nearby.

Hardness tester (main unit) Control unit

DUH-211/211S

10 Dynamic Ultra Micro Hardness Testers 11