Page 27 - Shimadzu AGX-V2 Series

P. 27

• Up to 5 optional units listed below can be installed.

Sensor amplifier (load cell, SG displacement meter, LVDT displacement meter), analog input amplifier (4CH), analog output amplifier (4CH),

Optional Functions strain amplifier (2CH), counter unit (4CH), PIO unit (16 inputs and 16 outputs), insulated PIO unit (16 inputs and 16 outputs), analog recorder unit

• Pneumatic or hydraulic grips interlocking operation

Standard Accessories Load cell, CAL cable, Tool set, Power supply cable, Rotating rod, Hexagon wrench, Instruction manual, Safety caution sheet (1 each)

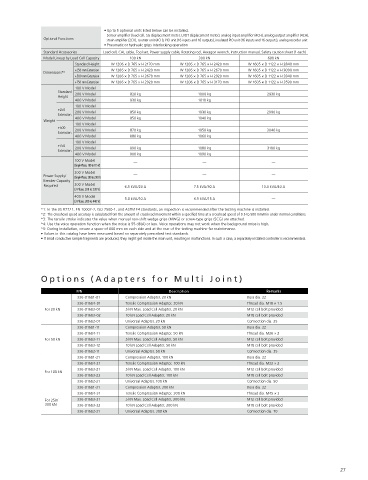

Model Lineup by Load Cell Capacity 100 kN 300 kN 600 kN

Standard Height W 1206 × D 765 × H 2170 mm W 1206 × D 765 × H 2420 mm W 1605 × D 1122 × H 2840 mm

+250 mm Extension W 1206 × D 765 × H 2420 mm W 1206 × D 765 × H 2670 mm W 1605 × D 1122 × H 3090 mm

Dimensions* 5

+500 mm Extension W 1206 × D 765 × H 2670 mm W 1206 × D 765 × H 2920 mm W 1605 × D 1122 × H 3340 mm

+750 mm Extension W 1206 × D 765 × H 2920 mm W 1206 × D 765 × H 3170 mm W 1605 × D 1122 × H 3590 mm

100 V Model — — —

Standard 200 V Model 820 kg 1000 kg 2930 kg

Height

400 V Model 830 kg 1010 kg —

AGX-100kNV2 AGX-300kNV2 AGX-600kNV2 100 V Model — — —

+250 200 V Model 850 kg 1030 kg 2990 kg

System Specifications Extension 400 V Model 850 kg 1040 kg —

Weight

100 V Model — — —

+500

Model Name AGX-100kNV2 AGX-300kNV2 AGX-600kNV2 200 V Model 870 kg 1050 kg 3040 kg

Extension

Max. Loading Capacity 100 kN 300 kN 600 kN 400 V Model 880 kg 1060 kg —

Loading Method AC servomotor drive 100 V Model — — —

+750

Within ±0.5% error of the indicated test force (in a range from 1/1000 to 1/100 of the load cell rated capacity) Within ±0.5 error % of the indicated test force Extension 200 V Model 890 kg 1080 kg 3100 kg

Within ±0.3 % error of the indicated test force (in a range from 1/100 to 1/1 of the load cell rated capacity) Compatible with JIS (in a range from 1/500 to 1/1 of the load cell rated capacity) 400 V Model 900 kg 1090 kg —

High-Accuracy Type

Compatible with JIS B7721 Class 0.5, EN 10002-2 Grade 0.5, ISO 7500-1 Class 0.5, BS 1610 Class 0.5, Compatible with JIS B7721 Class 0.5, EN 10002-2 Grade 0.5, ISO 7500-1 Class 0.5, 100 V Model

DIN 51221 Class 0.5, and ASTM E4 BS 1610 Class 0.5, DIN 51221 Class 0.5, and ASTM E4 — — —

(Single-Phase, 100 to 115 V)

Test Force Within ±1 % error of the indicated test force (in a range from 1/2000 to 1/1000 of the load cell rated capacity) 200 V Model

Measuring Within ±0.5 % error of the indicated test force (in a range from 1/1000 to 1/100 of the load cell rated capacity) Power Supply/ (Single-Phase, 200 to 230 V) — — —

Range* 1 Wide Ranging Type Within ±0.3 % error of the indicated test force (in a range from 1/100 to 1/1 of the load cell rated capacity) — Breaker Capacity

Compatible with JIS B7721 Class 1, EN 10002-2 Grade 1, ISO 7500-1 Class 1, BS 1610 Class 1, Required 200 V Model 6.5 kVA/20 A 7.5 kVA/30 A 13.0 kVA/40 A

DIN 51221 Class 1, and ASTM E4 (3-Phase, 200 to 230 V)

400 V Model

Within ±1 % error of the indicated test force 5.0 kVA/10 A 6.5 kVA/15 A —

(in a range from 1/1000 to 1/1 of the load cell rated capacity) (3-Phase, 380 to 440 V)

Compatible with JIS B7721 Class 1, EN 10002-2 Grade 1, Within ±1 % error of the indicated test force *1: In the JIS B7721, EN 10002-2, ISO 7500-1, and ASTM E4 standards, an inspection is recommended after the testing machine is installed.

ISO 7500-1 Class 1, BS 1610 Class 1, DIN 51221 Class 1, and ASTM E4

Standard- (in a range from 1/500 to 1/1 of the load cell rated capacity) *2: The crosshead speed accuracy is calculated from the amount of crosshead movement within a specified time at a crosshead speed of 0.5 to 500 mm/min under normal conditions.

Accuracy Type Within ±1 % error of the indicated test force Compatible with JIS B7721 Class 1, EN 10002-2 Grade 1, *3: The tensile stroke indicates the value when manual non-shift wedge grips (MWG) or screw-type grips (SCG) are attached.

(in a range from 1/500 to 1/1 of the load cell rated capacity) ISO 7500-1 Class 1, BS 1610 Class 1, DIN 51221 Class 1, and ASTM E4 *4: Use the voice operation function when the noise is 55 dB(A) or less. Voice operations may not work when the background noise is high.

Compatible with JIS B7721 Class 1, EN 10002-2 Grade 1, *5: During installation, ensure a space of 600 mm on each side and at the rear of the testing machine for maintenance.

ISO 7500-1 Class 1, BS 1610 Class 1, DIN 51221 Class 1, and ASTM E4 • Values in this catalog have been measured based on separately prescribed test standards.

• If small conductive sample fragments are produced, they might get inside the main unit, resulting in malfunctions. In such a case, a separately installed controller is recommended.

Crosshead Speed Range* 2 0.00005 to 1500 mm/min 0.00005 to 720 mm/min 0.00005 to 540 mm/min

Maximum Crosshead Return Speed 1800 mm/min 720 mm/min 540 mm/min

Crosshead Speed Accuracy ±0.1 %

Crosshead Speed and Permitted Test Force Up to the maximum load capacity for all speed ranges

Crosshead Position Measurement System Battery-less multi-turn absolute encoder

Detection Positional Accuracy Within ±0.05 % of the indicated value, but ±0.01 mm when the indicated value is below 20 mm

Crosshead Position Control Resolution 8.33 nm 3.33 nm 2.50 nm Options (Adapters for Multi Joint)

Standard 215 to 1250 215 to 1440 215 to 1650

Height (0 to 760) (0 to 630) (0 to 850) P/N Description Remarks

+250 mm 215 to 1475 215 to 1665 215 to 1875 336-01661-01 Compression Adapter, 20 kN Boss dia. 22

Crosshead-Table Extension (0 to 985) (0 to 855) (0 to 1075)

Clearance (mm) 336-01664-01 Tensile Compression Adapter, 20 kN Thread dia. M18 × 1.5

(Tensile Stroke)* 3 +500 mm 215 to 1700 215 to 1890 215 to 2100 For 20 kN 336-01663-01 5 kN Max. Load Cell Adapter, 20 kN M12 cell bolt provided

Extension (0 to 1210) (0 to 1080) (0 to 1300) 336-01663-02 10 kN Load Cell Adapter, 20 kN M18 cell bolt provided

+750 mm 215 to 1925 215 to 2115 215 to 2325 336-01662-01 Universal Adapter, 20 kN Connection dia. 25

Extension (0 to 1435) (0 to 1305) (0 to 1525) 336-01661-11 Compression Adapter, 50 kN Boss dia. 22

Effective Test Width 600 mm 790 mm 336-01664-11 Tensile Compression Adapter, 50 kN Thread dia. M26 × 2

Data Capture Rate 10 kHz max. For 50 kN 336-01663-11 5 kN Max. Load Cell Adapter, 50 kN M12 cell bolt provided

Direction of Tension 300 kN/mm 400 kN/mm 700 kN/mm 336-01663-12 10 kN Load Cell Adapter, 50 kN M18 cell bolt provided

Frame Rigidity

Direction of Compression 300 kN/mm 400 kN/mm 600 kN/mm 336-01662-11 Universal Adapter, 50 kN Connection dia. 35

• Test force/stress value display • Touch load detection • Test piece protection 336-01661-21 Compression Adapter, 100 kN Boss dia. 22

• Stroke display • Switching display languages to • Timer 336-01664-21 Tensile Compression Adapter, 100 kN Thread dia. M32 × 2

• Test force auto zero Japanese/English/Chinese language • Calculator 336-01663-21 5 kN Max. Load Cell Adapter, 100 kN M12 cell bolt provided

• Test force auto calibration • Switching display unit • Light For 100 kN 336-01663-22 10 kN Load Cell Adapter, 100 kN M18 cell bolt provided

• Automatic loading of load cell characteristic values • Standby Power Savings • Sound (Choose between standard and clear) 336-01662-21 Universal Adapter, 100 kN Connection dia. 50

• Fine adjustment of crosshead position (Button/Dial) • Self-check • Audio Output (Japanese/English/Chinese)

Standard Functions • Interlock function (Safety cover) • Auto return • 6 internal unit ports 336-01661-31 Compression Adapter, 300 kN Boss dia. 22

When the displacement gauge is connected • Setting Jig distance (One of the ports is dedicated to testing power.) 336-01664-31 Tensile Compression Adapter, 300 kN Thread dia. M45 × 3

• Displacement/strain value display function • Voice operation function *4 For 250/ 336-01663-31 5 kN Max. Load Cell Adapter, 300 kN M12 cell bolt provided

• Displacement auto zero When the operation controller is connected 300 kN 336-01663-32 10 kN Load Cell Adapter, 300 kN M18 cell bolt provided

• Displacement auto-calibration • Single test control function • Cycle test control function 336-01662-31 Universal Adapter, 300 kN Connection dia. 70

(Displacement gauge input amplifier only) • Stress automatic test control function

• Automatic test force/strain control (with autotuning function)

• Breakage detection • Soft limit detection

• Peak value/breakage value display • Crosshead speed preset function

• Test condition internal memory file function (25 files) • S-S curve display function

• USB flash drive connection function (window capture/real-time data sampling)

26 27