Page 220 - Shimadu Consumables Catalog

P. 220

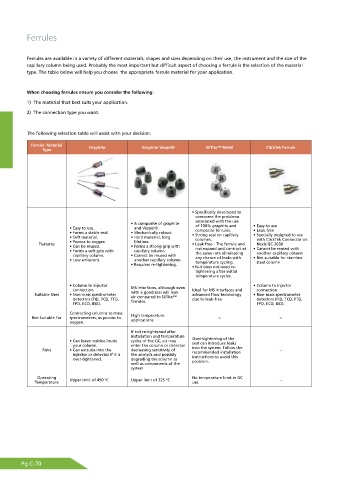

Ferrules

Ferrules are available in a variety of different materials, shapes and sizes depending on their use, the instrument and the size of the

capillary column being used. Probably the most important but difficult aspect of choosing a ferrule is the selection of the material

type. The table below will help you choose the appropriate ferrule material for your application.

When choosing ferrules ensure you consider the following:

1) The material that best suits your application.

2) The connection type you want.

The following selection table will assist with your decision.

Ferrule Material Graphite Graphite Vespel® SilTite™ Metal ClickTek Ferrule

Type

• Specifically developed to

overcome the problems

associated with the use

• A composite of graphite

• Easy to use. and Vespel®. of 100% graphite and • Easy to use

• Leak free

composite ferrules.

• Forms a stable seal. • Mechanically robust. • Strong seal on capillary • Specially designed to use

• Soft material. • Hard material, long columns. with ClickTek Connector on

• Porous to oxygen. lifetime.

Features • Leak free - The ferrule and Nexis GC-2030

• Can be reused. • Forms a strong grip with nut expand and contract at • Cannot be reused with

• Forms a soft grip with capillary column. the same rate eliminating another capillary column

capillary column. • Cannot be reused with

• Low emissions. another capillary column. any chance of leaks with • Not suitable for stainless

temperature cycling.

steel column

• Requires re-tightening.

• Nut does not need re-

tightening after initial

temperature cycles.

• Column to injector MS interfaces, although even • Column to injector

connection. Ideal for MS interfaces and connection

Suitable Uses • Non-mass spectrometer with a good seal will leak advanced flow technology • Non-mass spectrometer

air compared to SilTite™

detectors (FID, TCD, FTD, ferrules. due to leak-free detectors (FID, TCD, FTD,

FPD, ECD, BID). FPD, ECD, BID).

Connecting columns to mass

Not Suitable For spectrometers, as porous to High temperature − −

applications.

oxygen.

If not re-tightened after

installation and temperature

• Can leave residue inside cycles of the GC, air may Over-tightening of the

seal can introduce leaks

your column. enter the column or detector

Risks • Can extrude into the decreasing sensitivity of into the system. Follow the −

recommended installation

injector or detector if it is the analysis and possibly instructions to avoid this

over-tightened. degrading the column as problem.

well as components of the

system.

Operating No temperature limit in GC

Temperature Upper limit of 450 °C Upper limit of 325 °C use. −

Pg C-70