Page 8 - Automotive2-Railroad Industry

P. 8

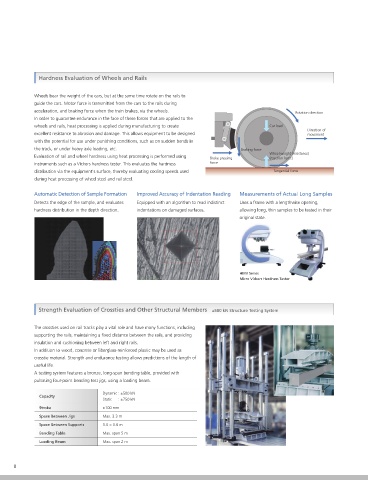

Hardness Evaluation of Wheels and Rails

Wheels bear the weight of the cars, but at the same time rotate on the rails to

guide the cars. Motor force is transmitted from the cars to the rails during

acceleration, and braking force when the train brakes, via the wheels. Rotation direction

In order to guarantee endurance in the face of these forces that are applied to the

wheels and rails, heat processing is applied during manufacturing to create Car load

Direction of

excellent resistance to abrasion and damage. This allows equipment to be designed movement

with the potential for use under punishing conditions, such as on sudden bends in

the track, or under heavy axle loading, etc. Braking force

Wheel weight (resistance)

Evaluation of rail and wheel hardness using heat processing is performed using Brake pressing (reaction force)

instruments such as a Vickers hardness tester. This evaluates the hardness force

distribution via the equipment's surface, thereby evaluating cooling speeds used Tangential force

during heat processing of wheel steel and rail steel.

Automatic Detection of Sample Formation Improved Accuracy of Indentation Reading Measurements of Actual Long Samples

Detects the edge of the sample, and evaluates Equipped with an algorithm to read indistinct Uses a frame with a lengthwise opening,

hardness distribution in the depth direction. indentations on damaged surfaces. allowing long, thin samples to be tested in their

original state.

HMV Series

Micro Vickers Hardness Tester

Strength Evaluation of Crossties and Other Structural Members ±500 kN Structure Testing System

The crossties used on rail tracks play a vital role and have many functions, including

supporting the rails, maintaining a fixed distance between the rails, and providing

insulation and cushioning between left and right rails.

In addition to wood, concrete or fiberglass-reinforced plastic may be used as

crosstie material. Strength and endurance testing allows predictions of the length of

useful life.

A testing system features a bronze, long-span bending table, provided with

pulsating four-point bending test jigs, using a loading beam.

Dynamic : ±500 kN

Capacity

Static : ±750 kN

Stroke ±100 mm

Space Between Jigs Max. 3.3 m

Space Between Supports 1.0 × 0.6 m

Bending Table Max. span 5 m

Loading Beam Max. span 2 m

8