Page 7 - Automotive2-Railroad Industry

P. 7

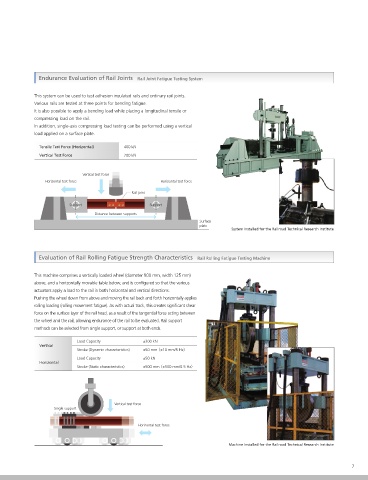

Endurance Evaluation of Rail Joints Rail Joint Fatigue Testing System

This system can be used to test adhesion insulated rails and ordinary rail joints.

Various rails are tested at three points for bending fatigue.

It is also possible to apply a bending load while placing a longitudinal tensile or

compressing load on the rail.

In addition, single-axis compressing load testing can be performed using a vertical

load applied on a surface plate.

Tensile Test Force (Horizontal) 400 kN

Vertical Test Force 200 kN

Vertical test force

Horizontal test force Horizontal test force

Rail joint

Support Support

Support

Distance between supports

Surface

plate

System Installed for the Railroad Technical Research Institute

Evaluation of Rail Rolling Fatigue Strength Characteristics Rail Rolling Fatigue Testing Machine

This machine comprises a vertically loaded wheel (diameter 900 mm, width 125 mm)

above, and a horizontally movable table below, and is configured so that the various

actuators apply a load to the rail in both horizontal and vertical directions.

Pushing the wheel down from above and moving the rail back and forth horizontally applies

rolling loading (rolling movement fatigue). As with actual track, this creates significant shear

force on the surface layer of the rail head, as a result of the tangential force acting between

the wheel and the rail, allowing endurance of the rail to be evaluated. Rail support

methods can be selected from single support, or support at both ends.

Load Capacity ±300 kN

Vertical

Stroke (Dynamic characteristics) ±50 mm ʢ±10 mm/5 Hzʣ

Load Capacity ±50 kN

Horizontal

Stroke (Static characteristics) ±500 mm ʢ±500 mm/0.5 Hzʣ

Vertical test force

Single support

Horizontal test force

Machine Installed for the Railroad Technical Research Institute

7