Page 17 - Automotive Aerospace

P. 17

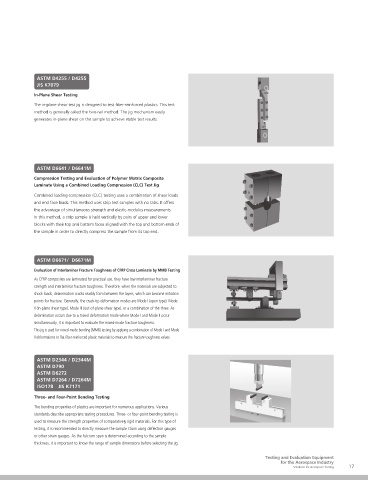

ASTM D4255 / D4255

JIS K7079

In-Plane Shear Testing

The in-plane shear test jig is designed to test fiber-reinforced plastics. This test

method is generally called the two-rail method. The jig mechanism easily

generates in-plane shear on the sample to achieve stable test results.

ASTM D6641 / D6641M

Compression Testing and Evaluation of Polymer Matrix Composite

Laminate Using a Combined Loading Compression (CLC) Test Jig

Combined loading compression (CLC) testing uses a combination of shear loads

and end face loads. This method uses strip test samples with no tabs. It offers

the advantage of simultaneous strength and elastic-modulus measurements.

In this method, a strip sample is held vertically by pairs of upper and lower

blocks with their top and bottom faces aligned with the top and bottom ends of

the sample in order to directly compress the sample from its top end.

ASTM D6671/ D6671M

Evaluation of Interlaminar Fracture Toughness of CFRP Cross Laminate by MMB Testing

As CFRP composites are laminated for practical use, they have low interlaminar fracture

strength and interlaminar fracture toughness. Therefore, when the materials are subjected to

shock loads, delamination cracks readily form between the layers, which can become initiation

points for fracture. Generally, the crack-tip deformation modes are Mode I (open type), Mode

II (in-plane shear type), Mode III (out-of-plane shear type), or a combination of the three. As

delamination occurs due to a mixed deformation mode where Mode I and Mode II occur

simultaneously, it is important to evaluate the mixed-mode fracture toughness.

This jig is used for mixed-mode bending (MMB) testing by applying a combination of Mode I and Mode

II deformations to flat fiber-reinforced plastic materials to measure the fracture toughness values.

ASTM D2344 / D2344M

ASTM D790

ASTM D6272

ASTM D7264 / D7264M

ISO178ɹJIS K7171

Three- and Four-Point Bending Testing

The bending properties of plastics are important for numerous applications. Various

standards describe appropriate testing procedures. Three- or four-point bending testing is

used to measure the strength properties of comparatively rigid materials. For this type of

testing, it is recommended to directly measure the sample strain using deflection gauges

or other strain gauges. As the fulcrum span is determined according to the sample

thickness, it is important to know the range of sample dimensions before selecting the jig.

Testing and Evaluation Equipment

for the Aerospace Industry

Solutions for Aerospace Testing 17