Page 32 - Automotive Solution for Automotive

P. 32

Reducing Weight Comfort/Convenience

Dynamic Tensile Testing Using a Three-Dimensional DIC Analysis System Evaluating the Performance of Suspension Parts

- Observation of Strain Distribution and Measurement of Strain in Polypropylene Just During travel, automotive suspension parts are subjected to loads from a variety of angles. To determine whether design results are good or bad, prototype

Prior to Fatigue Failure - performance is evaluated under simulated real-world travel conditions. However, simulating actual travel conditions requires simultaneously applying different

loads from multiple directions. The following shows a multi-axis system that simulates real-world travel conditions using a combination of multiple jacks.

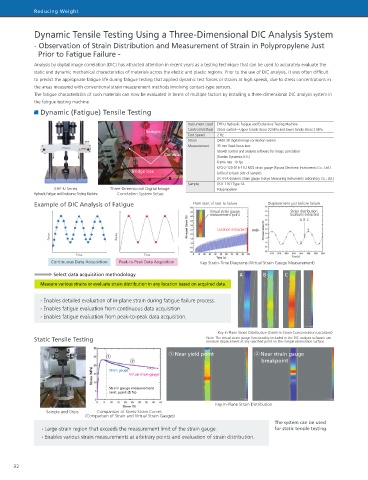

Analysis by digital image correlation (DIC) has attracted attention in recent years as a testing technique that can be used to accurately evaluate the

static and dynamic mechanical characteristics of materials across the elastic and plastic regions. Prior to the use of DIC analysis, it was often difficult Evaluating the Performance of Suspension Parts

to predict the appropriate fatigue life during fatigue testing that applied dynamic test forces or strains at high speeds, due to stress concentrations in

Sample Torque detector Torque actuator

Operating

the areas measured with conventional strain measurement methods involving contact-type sensors. Rubber Bushing Endurance Evaluation System Bearing Servo valve PC software

Lock nut Adjuster Lock nut Tie rod end

The fatigue characteristics of such materials can now be evaluated in terms of multiple factors by installing a three-dimensional DIC analysis system in Torque signal Tie rod

the fatigue testing machine. Driving signal

Controller

Angle signal

Dynamic (Fatigue) Tensile Testing Force signal

Force detector Driving signal

Displacement

Instrument Used EHF-U Hydraulic Fatigue and Endurance Testing Machine Actuator Servo valve signal

Sample Control Method Stress control—Upper tensile stress 20 MPa and lower tensile stress 2 MPa Accumulator Hydraulic power Tie rod

Test Speed 2 Hz Test frame source unit

Endurance Testing Machine with Thermostatic Lateral and Torsional Force Endurance

Strain Q400 3D digital image correlation system Chamber and Triaxial Loading Frame Testing Machine Note: Some interference may remain, depending on the sample

properties, test parameters, or other factors.

Measurement 35 mm fixed-focus lens

Istra4D control and analysis software for image correlation

Cameras

(Dantec Dynamics K.K.)

Frame rate: 10 fps

KFG-2-120-D16-11L1M2S strain gauge (Kyowa Electronic Instruments Co., Ltd.)

Bridge box (affixed to back side of sample)

DC-97A dynamic strain gauge (Tokyo Measuring Instruments Laboratory Co., Ltd.)

Sample JIS K 7161 Type 1A Wizard-driven easy setup. Setting confirmation screen. Confirm the result Performance wave reproduction test

EHF-U Series Three-Dimensional Digital Image Polypropylene in data viewer. is possible by correcting response

Hydraulic Fatigue and Endurance Testing Machine Correlation System Setup characteristics and mutual interference.

Example of DIC Analysis of Fatigue From start of test to failure Displacement just before failure

Virtual strain gauge Strain distribution

measurement point locations extracted · Iterations can correct for interference from other axes.

A B C

· Tests can simulate actual loading profiles by entering vibration waveforms measured during actual travel.

Location extracted

· Includes software that makes it easy to perform even complicated multi-axis testing.

Evaluating Shock Absorber Performance

Continuous Data Acquisition Peak-to-Peak Data Acquisition Key Strain-Time Diagrams (Virtual Strain Gauge Measurement)

The damping force vs. speed relationship is measured as test frequency is varied. Shock absorber performance can be confirmed by measuring

Select data acquisition methodology A B C the relationship between speed and damping force or the response to a Lissajous or other waveform. The input waveform is important for

evaluating slight differences in performance.

Measure various strains or evaluate strain distribution in any location based on acquired data.

· Enables detailed evaluation of in-plane strain during fatigue failure process. Shock Absorber Testing Software

Frequency sweep tests

· Enables fatigue evaluation from continuous data acquisition. Set half-amplitude and speed in stages. Test force (mm)

Includes auto-gain control (AGC) function

· Enables fatigue evaluation from peak-to-peak data acquisition. (amplitude correction function). Damping force (mm)

Can graph Lissajous and speed vs. damping

force waveforms.

Displacement (mm)

Key In-Plane Strain Distribution (Confirm Strain Concentration Locations) Lissajous Waveform

Static Tensile Testing Note: The virtual strain gauge functionality included in the DIC analysis software can • Settings can be configured easily via a wizard interface. Speed (mm/s)

measure displacement at any specified point on the sample observation surface.

• Lissajous and speed vs. damping force waveforms can be graphed easily. Speed vs. Damping Force Waveform

① ① Near yield point ② Near strain gauge

② breakpoint

Strain gauge

Virtual strain gauge

Frequency-sweep

AGC function

Strain gauge measurement Initial load adjustment cylinder

limit point (5 %) If tests are affected by servo valve frequency characteristics However, the frequency-sweep AGC function corrects

or PID control settings are inadequate, then the amplitude the amplitude to keep it constant at all frequency

Vertical load ±10 kN can vary depending on the frequency, as shown above. levels.

Key In-Plane Strain Distribution Piston stroke ±50 mm Servo Controller 4830

Sample and Grips Comparison of Stress-Strain Curves Max. speed 2 m/s • High-resolution 24-bit measurement • High-speed 10 kHz feedback loop achieves loading waveforms with high reproducibility.

• Frequency-sweep AGC function (amplitude correction function) controls amplitude to a constant level.

(Comparison of Strain and Virtual Strain Gauges)

The system can be used

· Large-strain region that exceeds the measurement limit of the strain gauge. for static tensile testing. · The high-speed response and high resolution provide faithful waveforms. Even slight performance differences can be

· Enables various strain measurements at arbitrary points and evaluation of strain distribution. expressed numerically.

32 33