Page 35 - Shimadzu Journal vol.10 Issue1

P. 35

MIV-X Ultrasonic Optical

Flaw Detector

Latest topics 5

Ultrasonic Optical Flaw Detector

Shimadzu Corporation announces the release of the MIV-X ultrasonic transportation equipment and machinery, raw materials, and construc-

optical flaw detector. This product visualizes and digitizes flaws, such tion, as well as research agencies engaged in the development of mul-

as peeling, cracks, and voids, in parts and multi-materials in aircraft, ti-materials and other new materials.

automobiles, and electrical and electronic equipment using our pro-

prietary ultrasonic optical flaw detection technology*, which captures *This technology is patented in Japan, China, and the United States.

images of the ultrasonic propagation on the surface of an object. While

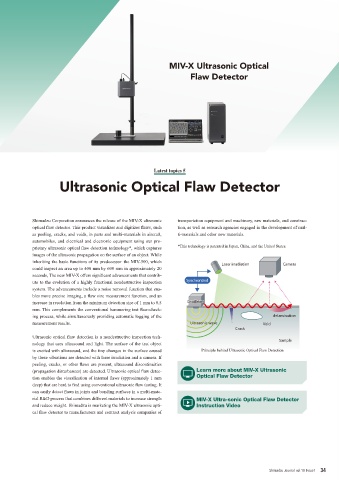

inheriting the basic functions of its predecessor–the MIV-500, which Laser irradiation Camera

could inspect an area up to 400 mm by 600 mm in approximately 20

seconds, The new MIV-X offers significant advancements that contrib-

ute to the evolution of a highly functional nondestructive inspection Synchronized

system. The advancements include a noise removal function that ena-

bles more precise imaging, a flaw size measurement function, and an

increase in resolution from the minimum detection size of 1 mm to 0.5 Oscillator

mm. This complements the conventional hammering test flaw-check-

ing process, while simultaneously providing automatic logging of the delamination

measurement results. Ultrasonic wave Void

Crack

Ultrasonic optical flaw detection is a nondestructive inspection tech-

nology that uses ultrasound and light. The surface of the test object Sample

is excited with ultrasound, and the tiny changes in the surface caused Principle behind Ultrasonic Optical Flaw Detection

by these vibrations are detected with laser irradiation and a camera. If

peeling, cracks, or other flaws are present, ultrasound discontinuities

(propagation disturbances) are detected. Ultrasonic optical flaw detec- Learn more about MIV-X Ultrasonic

tion enables the visualization of internal flaws (approximately 1 mm Optical Flaw Detector

deep) that are hard to find using conventional ultrasonic flaw testing. It

can easily detect flaws in joints and bonding surfaces in a multi-mate-

rial R&D process that combines different materials to increase strength MIV-X Ultra-sonic Optical Flaw Detector

and reduce weight. Shimadzu is marketing the MIV-X ultrasonic opti- Instruction Video

cal flaw detector to manufacturers and contract analysis companies of

Shimadzu Journal vol.10 Issue1 34