Page 3 - Kratos AXIS Nova

P. 3

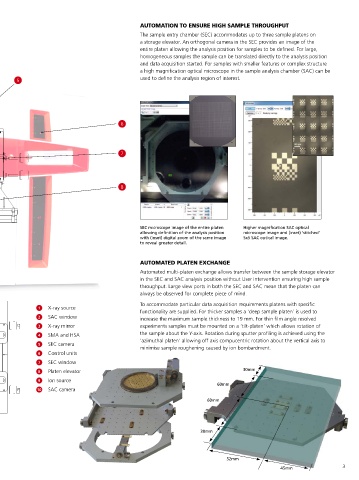

X-RAY PHOTOELECTRON 4 AUTOMATION TO ENSURE HIGH SAMPLE THROUGHPUT

SPECTROSCOPY The sample entry chamber (SEC) accommodates up to three sample platens on

a storage elevator. An orthogonal camera in the SEC provides an image of the

X-ray photoelectron spectroscopy (XPS), also known as entire platen allowing the analysis position for samples to be defined. For large,

electron spectroscopy for chemical analysis (ESCA), is

3 homogeneous samples the sample can be translated directly to the analysis position

a widely used surface analysis technique for materials and data acquisition started. For samples with smaller features or complex structure

characterisation. With a standard Al Ka excitation a high magnification optical microscope in the sample analysis chamber (SAC) can be

source, the technique provides quantitative elemental used to define the analysis region of interest.

and chemical state information from the upper most 5

10 nm of a material. XPS is used in diverse applications,

ranging from defect analysis on microelectronic bond-

pads to drug eluting thin films in the pharmaceutical

industry.

STATE-OF-THE-ART PERFORMANCE 6

2

The AXIS Nova combines XPS imaging and

spectroscopic capabilities with a highly automated,

large sample handling system and is the next 7

2

generation of AXIS Nova spectrometer. The AXIS Nova 2

provides enhanced performance over its predecessor

and is based on Kratos’ proven AXIS technology

comprising: magnetic and electrostatic transfer lenses;

co-axial electron-only charge neutralisation; spherical 8

mirror and hemispherical electron energy analysers.

Kratos developed innovations such as the delay-line

detector for spectroscopy and imaging modes and 1

high energy X-ray excitation sources ensure the AXIS

2

Nova is capable of performing in the most demanding

research and development environments. SEC microscope image of the entire platen Higher magnification SAC optical

allowing definition of the analysis position microscope image and (inset) ‘stitched’

with (inset) digital zoom of the same image 5x5 SAC optical image.

Designed for ease of use, the AXIS Nova has to reveal greater detail.

2

automated sample loading, orthogonal cameras for

easy sample positioning and intuitive data acquisition AUTOMATED PLATEN EXCHANGE

2

software. A unique capability of the AXIS Nova is the

110mm diameter sample platen allowing unrivalled Automated multi-platen exchange allows transfer between the sample storage elevator

large sample handling and high sample throughput. in the SEC and SAC analysis position without User intervention ensuring high sample

None of these attributes compromise the performance. throughput. Large view ports in both the SEC and SAC mean that the platen can

2

The AXIS Nova is capable of high sensitivity, excellent always be observed for complete piece of mind.

energy resolution and fast, high spatial resolution To accommodate particular data acquisition requirements platens with specific

imaging meeting the analysis needs of the most 1 X-ray source functionality are supplied. For thicker samples a ‘deep sample platen’ is used to

challenging applications. 2 SAC window increase the maximum sample thickness to 19 mm. For thin film angle resolved

3 X-ray mirror experiments samples must be mounted on a ‘tilt-platen’ which allows rotation of

COMPACT FOOTPRINT the sample about the Y-axis. Rotation during sputter profiling is achieved using the

4 SMA and HSA

The AXIS Nova is designed as a single unit with a 10 5 SEC camera ‘azimuthal platen’ allowing off axis compucentric rotation about the vertical axis to

2

compact footprint measuring 2.06 x 1.07m. Additional minimise sample roughening caused by ion bombardment.

space is required for a small closed loop water chiller 6 Control units

and computer desk. Services required include dry 7 SEC window

nitrogen vent gas, argon for ion sputtering and 8 Platen elevator 30mm

compressed air for pneumatic valves all of which are 9 Ion source

input via a discrete fluids panel at the rear of the 60mm

spectrometer. The vacuum chamber has integrated 3 10 SAC camera

heaters and baking covers for easy computer controlled 60mm

bake-out of the system when required.

9

30mm

Path of sample platens from the Sample Entry

Chamber (SEC) to the Sample Analysis Chamber

(SAC). Up to three platens can be stacked

vertically in the SEC, on a storage elevator. 52mm

2 45mm 3