Page 9 - Shimadzu GCMS-TQ8040 NX

P. 9

Smart Productivity

The GC/MS is now a standard system for analysts, and a system can be used for a wide variety of applications. The Time Management for Continuous Analysis

active time management feature appropriately manages times when the system requires maintenance, or when system

changes are being made, or the waiting time for a user when multiple users are waiting to use the system. This ensures By displaying the time required for continuous analysis in real time, the time when the current continuous analysis will finish

more efficient use of the system and greater uptime. can be accurately confirmed. This increases the instrument operating time (active time) by reducing standby time required

during continuous analysis or while switching between different users. In addition, because this function makes it easier to

schedule the timing for analysis preparations, such as sample preparation and pretreatment, based on the finish time of the

™

Active-Time Management That Accurately Determines Operation Time previous analysis, it enables analytical processes to be performed more efficiently, which can help improve work-life balance.

Time Management during Instrument Startup/Shutdown

The mass spectrometer has to be operated in a vacuum condition, the startup and stopping of the system takes time depend-

ing on the condition. Determining this can be a challenge. Since the amount of time that the system takes when starting up or

stopping is displayed in real time, it is easy to accurately determine when maintenance of the ion source or analysis is possible.

Moreover, tasks that until now needed to be performed by the user, such as leak checks upon system startup and auto tuning,

are now performed automatically.

Auto Startup and Shutdown

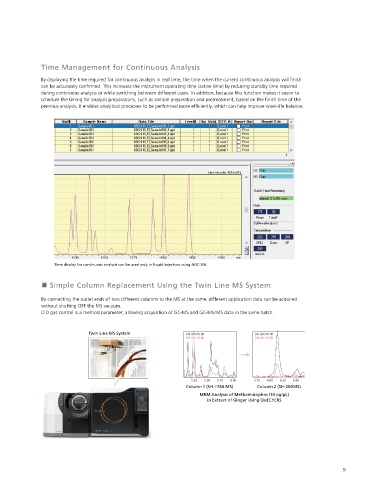

Time display for continuous analysis can be used only in liquid injection using AOC-20i.

Auto Tuning Check Result

Simple Column Replacement Using the Twin Line MS System

By connecting the outlet ends of two different columns to the MS at the same, different application data can be acquired

Time Management during Injection Port Maintenance without shutting OFF the MS vacuum.

CID gas control is a method parameter, allowing acquisition of GC-MS and GC-MS/MS data in the same batch.

The Easy sTop function, used to safely maintain the sample injection port without releasing the vacuum, displays the remaining

time (cooling-down time) when the septum or the insert can be replaced in real time. Maintenance time can be minimized by

understanding the accurate remaining time. Twin Line MS System 141.00>95.00 141.00>95.00

Furthermore, by using a ClickTek nut on the top of the sample injection port, the port can be opened or closed without tools, 141.00>79.00 141.00>79.00

by simply using fingers to twist a lever. That enables faster and easier insert replacement than ever before.

5.25 5.50 5.75 6.00 5.75 6.00 6.25 6.50

Column 1 (SH-I-5Sil MS) Column 2 (SH-200MS)

MRM Analysis of Methamidophos (10 pg/µL)

in Extract of Ginger Using QuEChERS

Easy sTop Function ClickTek Nut

8 9