Page 22 - Shimadzu EPMA-8050G

P. 22

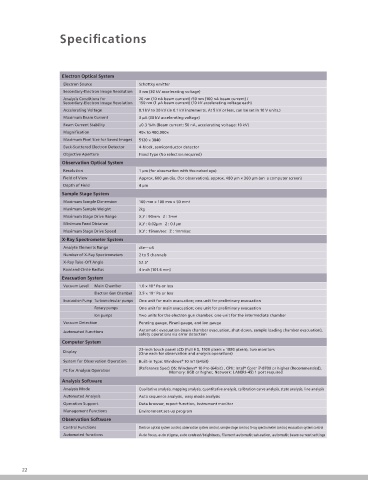

Specifications Installation Requirements

Electron Optical System Ambient Conditions Gas

• Temperature 18 °C to 28 °C • PR Gas Mixture of Ar (Argon) + CH4 (Methane) 10vol%.

Electron Source Schottky emitter

(Provide an air conditioning system to control temperature fluctuation within ±1 °C.) Pressure: 1 kPa to 3 kPa

Secondary-Electron Image Resolution 3 nm (30 kV accelerating voltage) • Humidity 30%RH to 60%RH Flow rate: 10 mL/min to 14 mL/min

Analysis Conditions for 20 nm (10 nA beam current) /50 nm (100 nA beam current) / • Heat Generation Rate When used with natural cooling water discharged: Connection port: Connect a gas cylinder filled to the following specifications.

Secondary-Electron Image Resolution 150 nm (1 A beam current) (10 kV accelerating voltage each) Gas filling pressure: 15 MPa max.

Approx. 2.5 kW

Accelerating Voltage 0.1 kV to 30 kV (in 0.1 kV increments. At 5 kV or less, can be set in 10 V units.) When used with cooling water circulation unit: Cylinder port : W22 - 14 right-handed male screw

Approx. 3.3 kW (including heat generated by that unit)

Maximum Beam Current 3 A (30 kV accelerating voltage)

Installation Room • Compressed Air Prepare the following compressed air sources for driving

Beam Current Stability ±0.3 %/h (Beam current: 50 nA, accelerating voltage: 10 kV) the air valves and air dampers. (Two systems)

• Floor Area W4m min.×D3.5m min.×H2.5m min.

Magnification 40× to 400,000× Pressure: 0.45 MPa to 0.6 MPa; connection port: Rc 1/4

• Door Width: 1.25 m min., height: 1.8 m min.

Maximum Pixel Size for Saved Images 5120 × 3840 Power Requirements • Dry Nitrogen Gas (EPMA-1720H only. Recommended for purging electron gun when using CeB6.)

Back-Scattered Electron Detector 4-block, semiconductor detector • Analyzer Single phase 200 V AC ±10%, 30 A, 50/60 Hz, 1 circuit Pressure : 0.08 MPa to 0.1 MPa

Objective Aperture Fixed Type (No selection required) • PC Single phase 100 to 240V AC±10%,5A 50/60Hz,1 circuit Connection port: Joint for tube with 6 mm diameter

Observation Optical System • Ion Pump Backup Power Supply Vibration and Stray Magnetic Fields

Single phase 200 V AC ±10%, 30 A, 50/60 Hz, 1 circuit Indicated in the Pre-Installation Requirements. For more information, contact your Shimadzu representative.

Resolution 1 m (for observation with the naked eye)

Grounding Resistance

Field of View Approx. 600 m dia. (for observation), approx. 480 m × 360 m (on a computer screen) • 100 max. Laws and Regulations

Depth of Field 4 m Cooling Water To prevent X-ray radiation accidents, safety regulations and standards

Sample Stage System • Water Supply Water pressure: 0.08 MPa to 0.18 MPa for devices equipped with X-ray generators have been established in

Water temperature: 20 °C to 25 °C each country. Observe the laws and regulations for X-ray generators that

Maximum Sample Dimension 100 mm × 100 mm × 50 mm t Flow rate: 0.7 L/min are applicable in the country where the product is used. For notifications

Maximum Sample Weight 2kg Faucet outer diameter: 11mm. on installation and safety controls, follow the necessary procedures in

Maximum Stage Drive Range X,Y : 90mm Z : 7mm • Water Drainage Natural drainage (same height as floor) compliance with the laws and regulations applicable in the country

where the product is used.

Minimum Feed Distance X,Y : 0.02 m Z : 0.1 m

Maximum Stage Drive Speed X,Y : 15mm/sec Z : 1mm/sec (1) Rated output: 30 kV, 1 mA max.

(2) Dose rate:1 Sv/h or less.

X-Ray Spectrometer System

Analyte Elements Range 4Beʙ92U Layout Example

Number of X-Ray Spectrometers 2 to 5 channels

400 min.

X-Ray Take-Off Angle 52.5° 4000 min. Unit: mm

Rowland Circle Radius 4 inch (101.6 mm) 1300

Evacuation System

Electrical Air compressor

Vacuum Level Main Chamber 1.0 × 10 Pa or less Distribution panel Cooling water

-3

Electron Gun Chamber 3.5 × 10 Pa or less circulation unit

-7

Evacuation Pump Turbomolecular pumps One unit for main evacuation; one unit for preliminary evacuation

Control Unit

Rotary pumps One unit for main evacuation; one unit for preliminary evacuation Height 750 Power

Ion pumps Two units for the electron gun chamber; one unit for the intermediate chamber 860 220 kg Supply Rack RP

200 kg

Vacuum Detection Penning gauge, Pirani gauge, and ion gauge Flow Switch Box

Automated Functions Automatic evacuation (main chamber evacuation, shut-down, sample loading chamber evacuation),

safety operations via error detection

RP Weight

Computer System

Main Unit 3500 min.

23-inch touch panel LCD (Full HD, 1920 pixels × 1080 pixels), two monitors

Display (One each for observation and analysis operations) Height 1910 1260

Interior of Room 800 kg IP

System for Observation Operation Built-in Type: Windows 10 IoT (64bit) Height 2500 min. Rack

®

®

®

(Reference Spec) OS: Windows 10 Pro (64bit) , CPU: Intel Core i7-8700 or higher (Recommended), 70 kg

™

PC for Analysis Operation Memory: 8GB or higher, Network: LAN(RJ-45) 1 port required

Analysis Software

Dry

Analysis Mode Qualitative analysis, mapping analysis, quantitative analysis, calibration curve analysis, state analysis, line analysis nitrogen

gas

Automated Analysis Auto sequence analysis, easy mode analysis 900 min.

Operation Support Data browser, report function, instrument monitor PR gas

Management Functions Environment set-up program

Observation Software Entrance

Width 1250 min. 1260 800 min.

Control Functions Electron optical system control, observation system control, sample stage control, X-ray spectrometer control, evacuation system control Height 1800 min.

Automated functions Auto focus, auto stigma, auto contrast/brightness, filament automatic saturation, automatic beam current settings

Note) Parts shown in broken lines are not included in the standard configuration.

EPMA-8050G

Electron Probe Microanalyzer

22 23